An automatic glue spraying mechanism

A glue-spraying and automatic technology, which is applied in the direction of coating and liquid-coating devices on the surface, can solve the problems of inaccurate lamination position and high labor intensity, and achieve high bonding strength, high degree of automation and labor saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

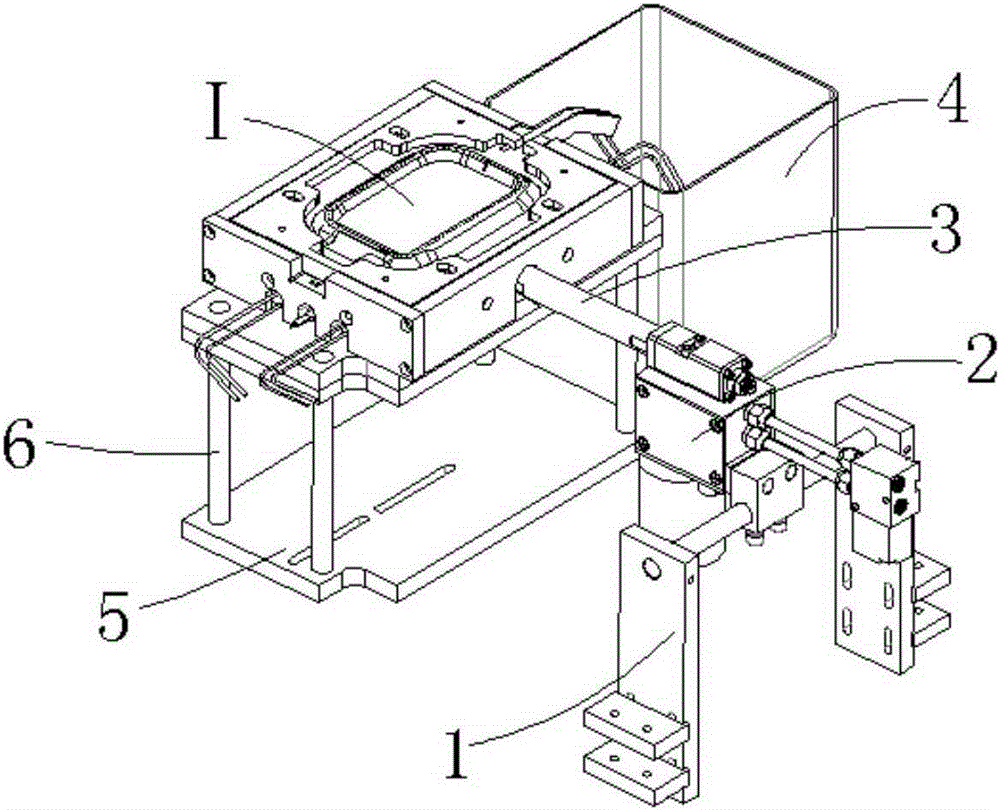

[0022] Examples, see attached Figure 1-5 , an automatic glue spraying mechanism, which includes a glue gun base 1, a glue gun 2, a rubber hose 3, a waste bucket 4, a bottom plate 5, a support column 6 and a glue discharge mechanism I, and the glue gun is installed on the glue gun base; The glue gun is connected with a rubber hose; four support columns are installed on the base plate, the glue outlet mechanism is installed on the four support columns, and the waste barrel is located on the right side of the glue outlet mechanism; the glue hose is connected with the glue outlet The mechanism is connected, and the glue outlet mechanism is connected with the waste barrel.

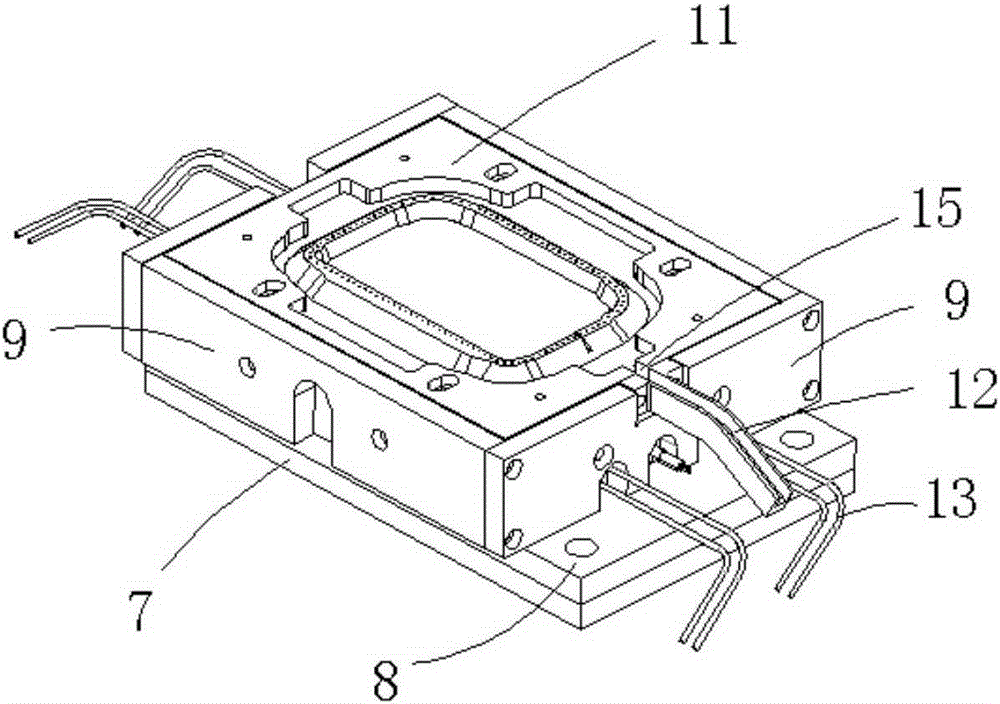

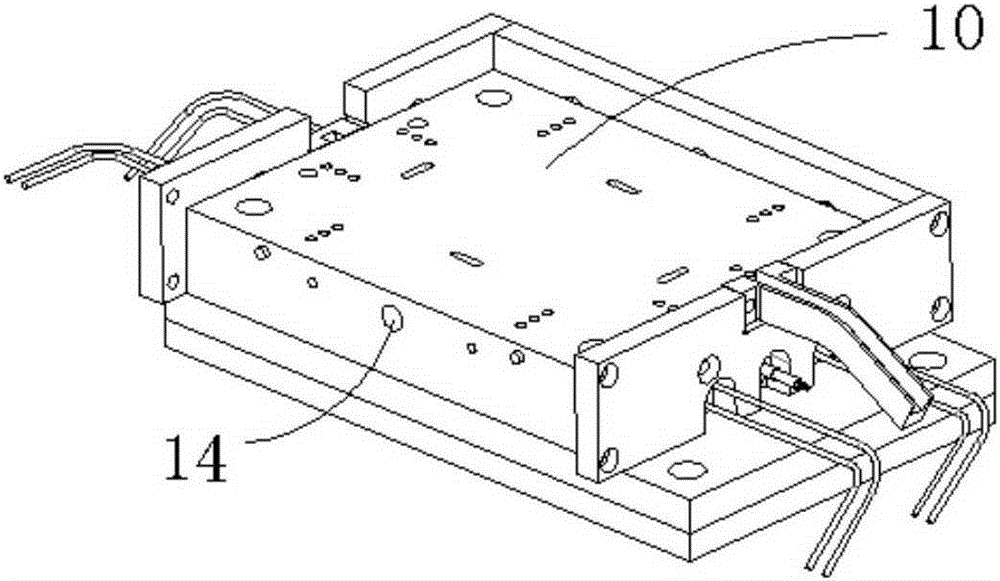

[0023] The glue outlet mechanism includes a connection plate 7, a heating base plate 8, a glue outlet plate block 9, a glue outlet heating plate 10, a glue outlet plate 11, a waste channel 12 and a heating rod 13, and the connection plate is fixed to four supporting columns Connected together; the heating bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com