Bending machine die for nine-bend workpiece and machining method of nine-bend workpiece

A bending machine and mold technology, applied in the field of molds and bending, can solve the problem that a special nine-fold workpiece cannot be used, and achieve the effects of low processing cost, stable performance and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

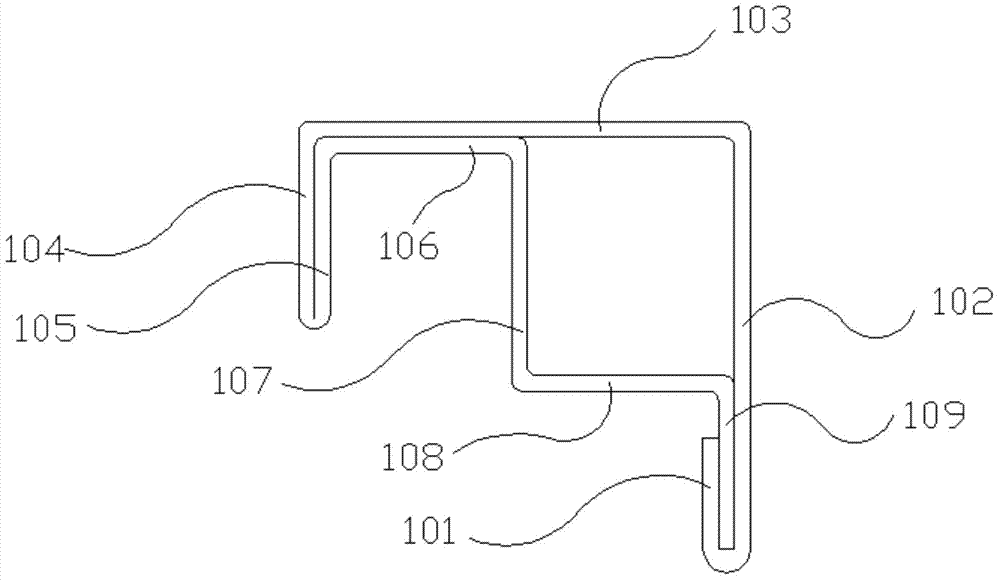

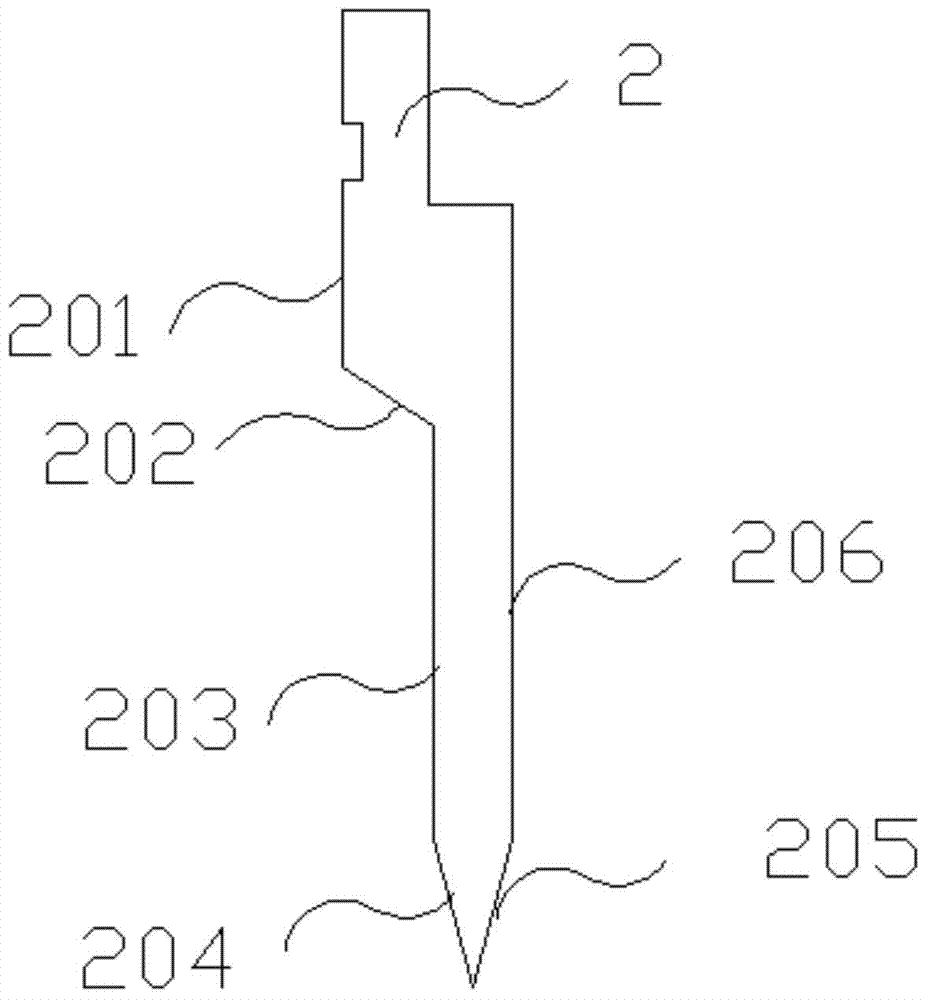

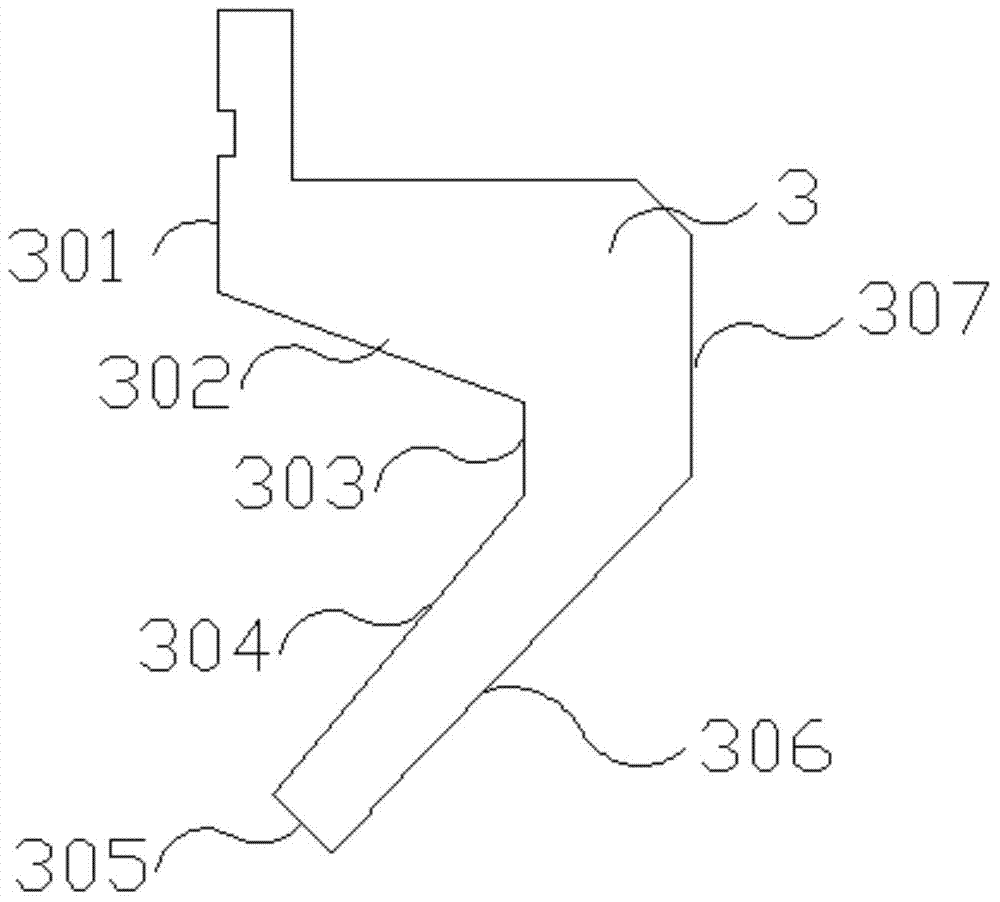

[0050] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, a bending machine mold for a nine-fold workpiece includes a lower mold and an upper mold, and the upper mold includes a first upper mold 2, a second upper mold 3, a third upper mold 4 and a fourth upper mold 5;

[0051] The lower part of the first upper mold 2 is composed of the first upper mold first vertical surface 201, the first upper mold first inclined surface 202, the first upper mold second vertical surface 203, the first upper mold second inclined surface 204, the first upper mold second inclined surface 204, A third upper mold inclined plane 205 and a first upper mold third vertical plane 206 are sequentially connected to form; the included angle between the first upper mold second vertical plane 203 and the first upper mold second inclined plane 204 is 165°; the angle between the second inclined surface 204 of the first upper mold and the third inclined surface 205 of ...

Embodiment 2

[0065] Same as Example 1, the difference is that the order of step (7) and step (6) is reversed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com