Double-sided molding grinding machine

A double-sided forming and grinding machine technology, applied in grinding machines, grinding machine parts, machine tools suitable for grinding workpiece planes, etc., can solve the problems of low processing efficiency, increasing the manufacturing cost of forming grinding machines, and inability to guarantee processing accuracy, etc. Achieve the effect of improving processing efficiency and ensuring forming processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

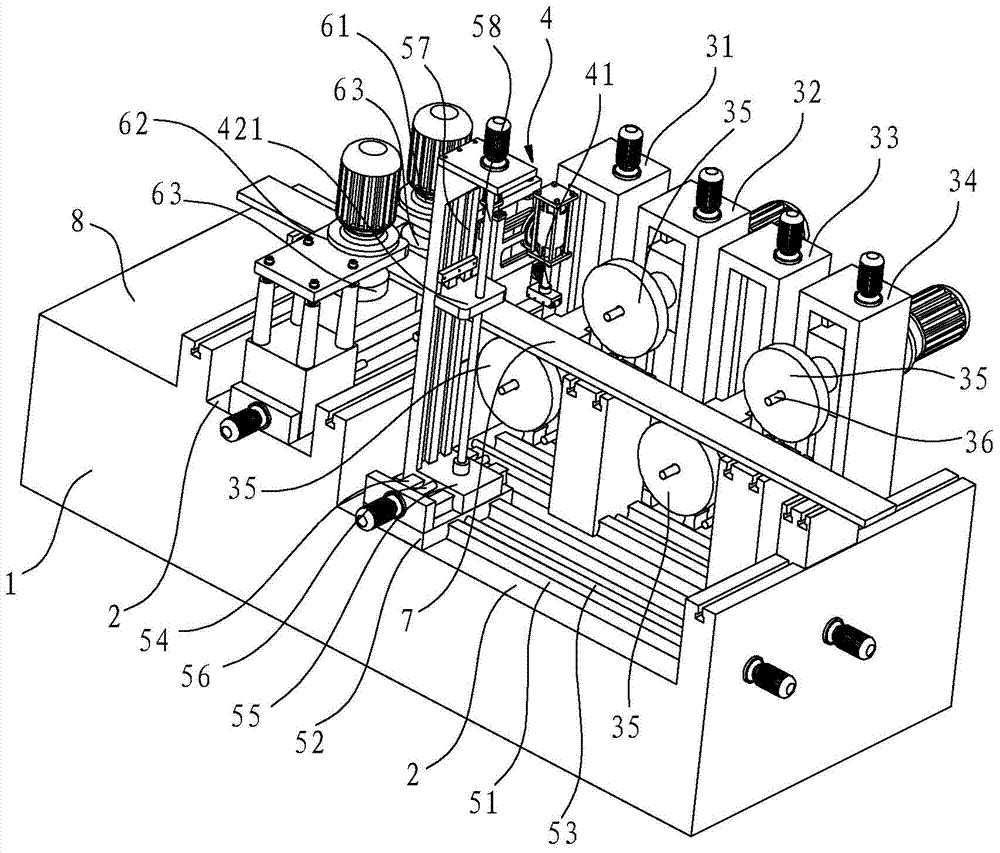

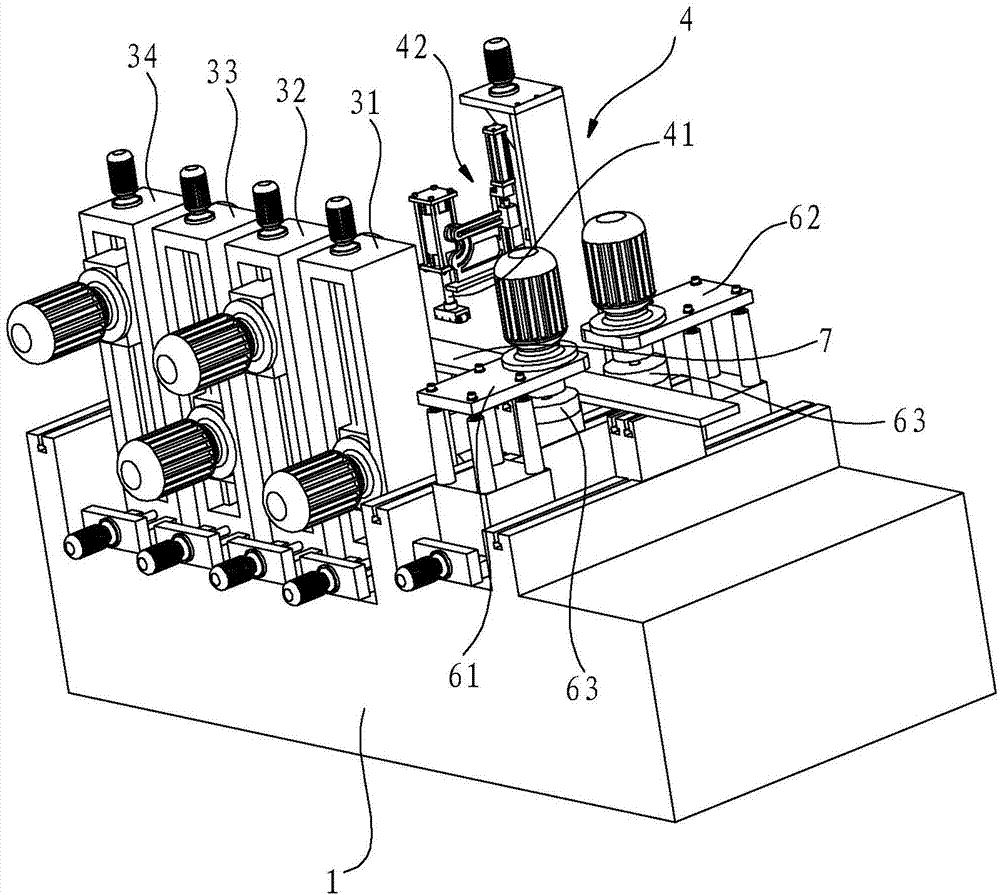

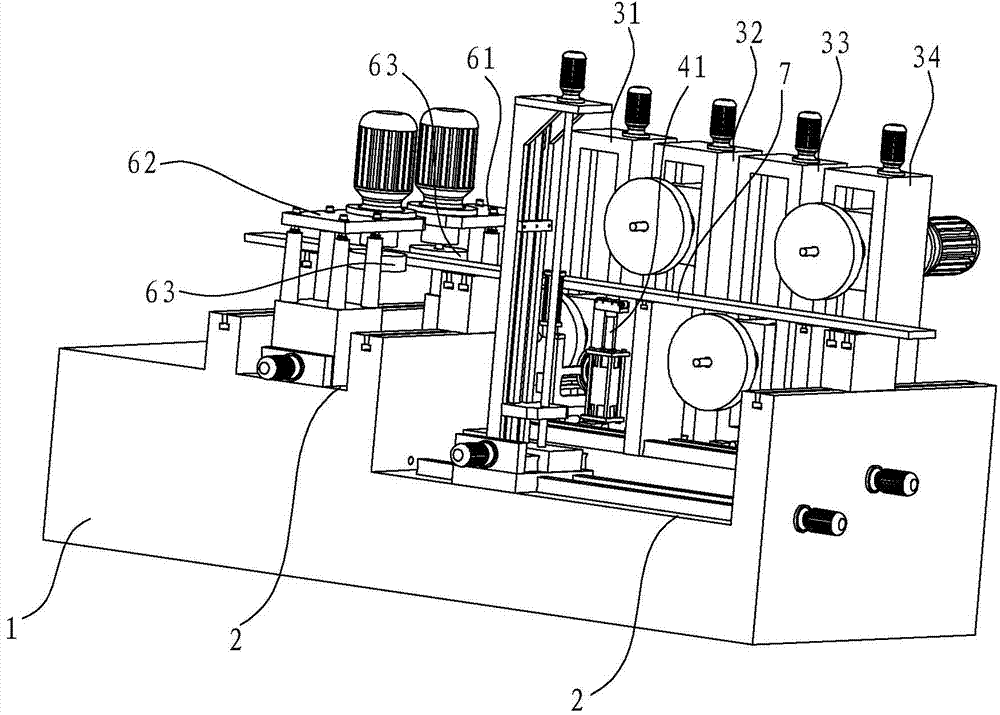

[0035] like Figure 1 to Figure 3 As shown, the double-sided forming grinding machine in this embodiment includes a machine tool base 1 and a machine tool feed table 8 and a workpiece grinding table 2 installed on the machine base 1. The feeding direction of the workpiece 7 is the horizontal direction. Four groups of grinding mechanisms are arranged in sequence along the workpiece feeding direction on the grinding table 2, and the four groups of grinding mechanisms are arranged side by side on one side of the workpiece feeding direction, and the axes of the grinding wheel rotating spindles 36 of each group of grinding mechanisms are mutually horizontal. Distributed in parallel and perpendicular to the feed direction of the workpiece. When the grinding mechanism is in working condition, the positions of the grinding wheels 35 of the four group...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap