Integrated A/O/MBBR (Moving Bed Biofilm Reactor) reactor

A technology for reactors and anoxic zones, applied in the field of integrated A/O/MBBR reactors, which can solve the problems of large footprint, scattered layout, and complicated process, and achieve small footprint, reduced disturbance, and low noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

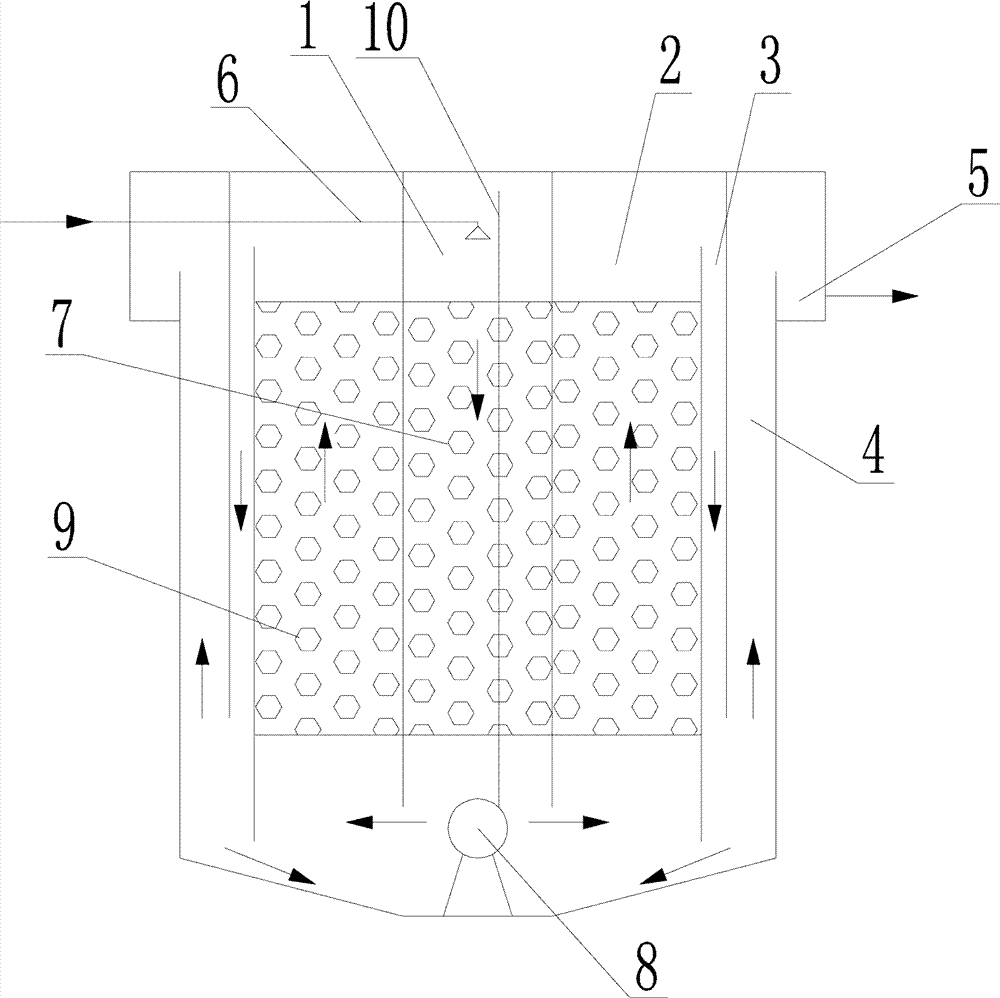

[0008] The specific embodiment: the present invention will be further described below in conjunction with the specific embodiment of accompanying drawing, figure 1 The structure shown is one of the preferred structures of the present invention. It is an integrated A / O / MBBR reactor, which mainly includes anoxic zone 1, aerobic zone 2, and guide zone separated by several concentric cylindrical partitions. The circular cylinder of the flow area 3, the mud-water separation area 4 and the water collection area 5, the water inlet and distribution device 6 arranged on the upper part of the anoxic area 1, the suspended filler 7 arranged in the middle of the anoxic area 1, and the The submersible centrifugal aerator 8 at the bottom of zone 1, the suspended filler 9 arranged in the middle of the aerobic zone 2, and the air inlet pipe 10 connected to the inlet of the submersible centrifugal aerator 8. The anoxic zone 1 communicates with the bottom of the aerobic zone 2, the aerobic zone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com