Purity and turbidity separation collection method of printing and dyeing wastewater with conductivity as index

A technology for wastewater collection, printing and dyeing wastewater, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. problems, to achieve the effect of improving production efficiency, high accuracy, and reducing process load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

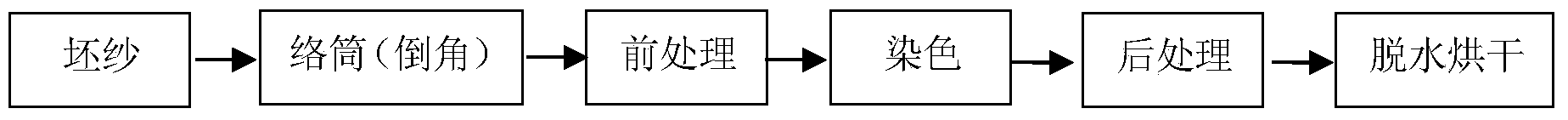

[0029] Step 1: Research on the use of dyes and auxiliaries in the dyeing workshop and the production process.

[0030] The following table shows the research results of the corresponding dyeing process and the use of dyes and auxiliaries:

[0031] Table 1 The use of dyes and auxiliaries for yarn package dyeing

[0032]

[0033] Step two:

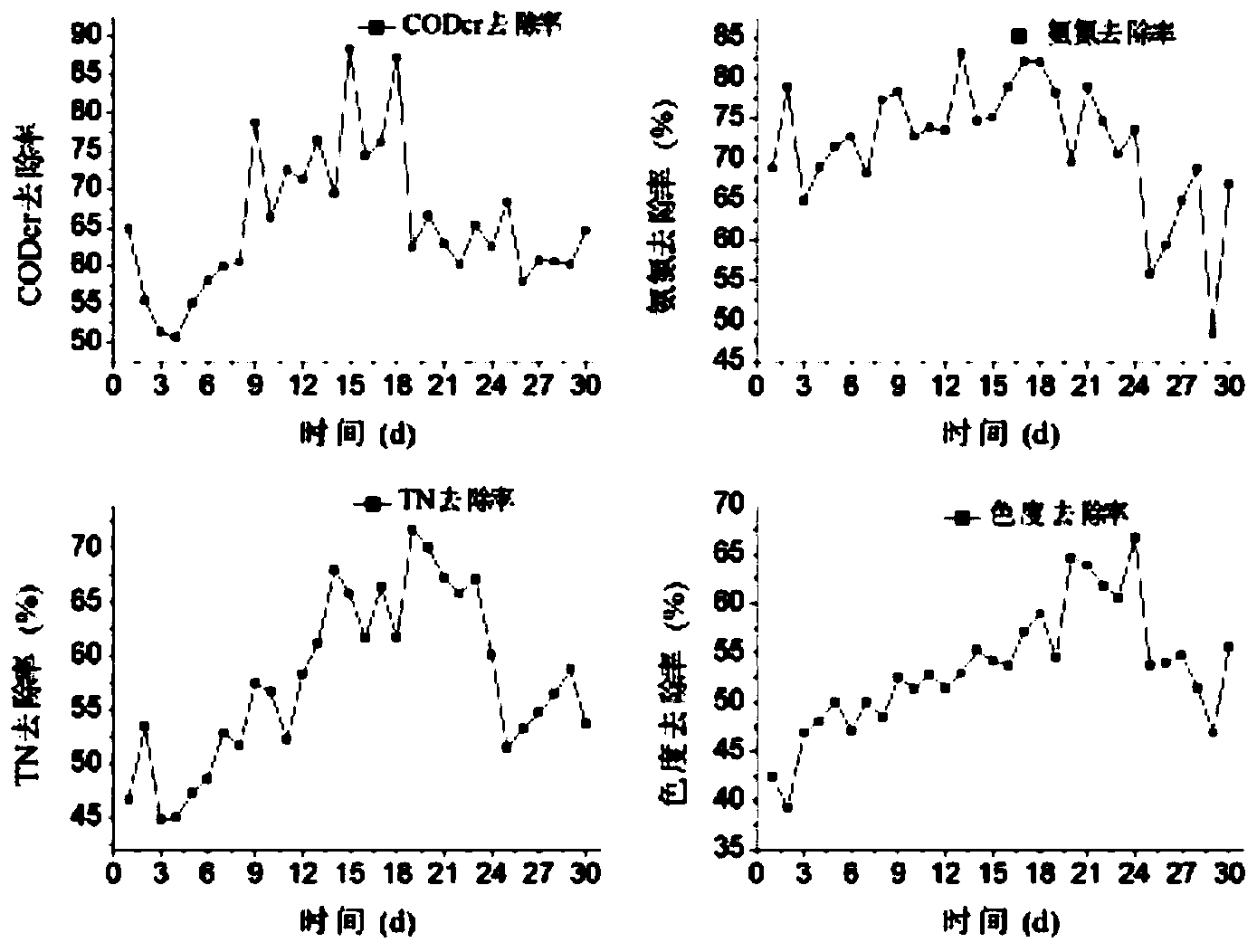

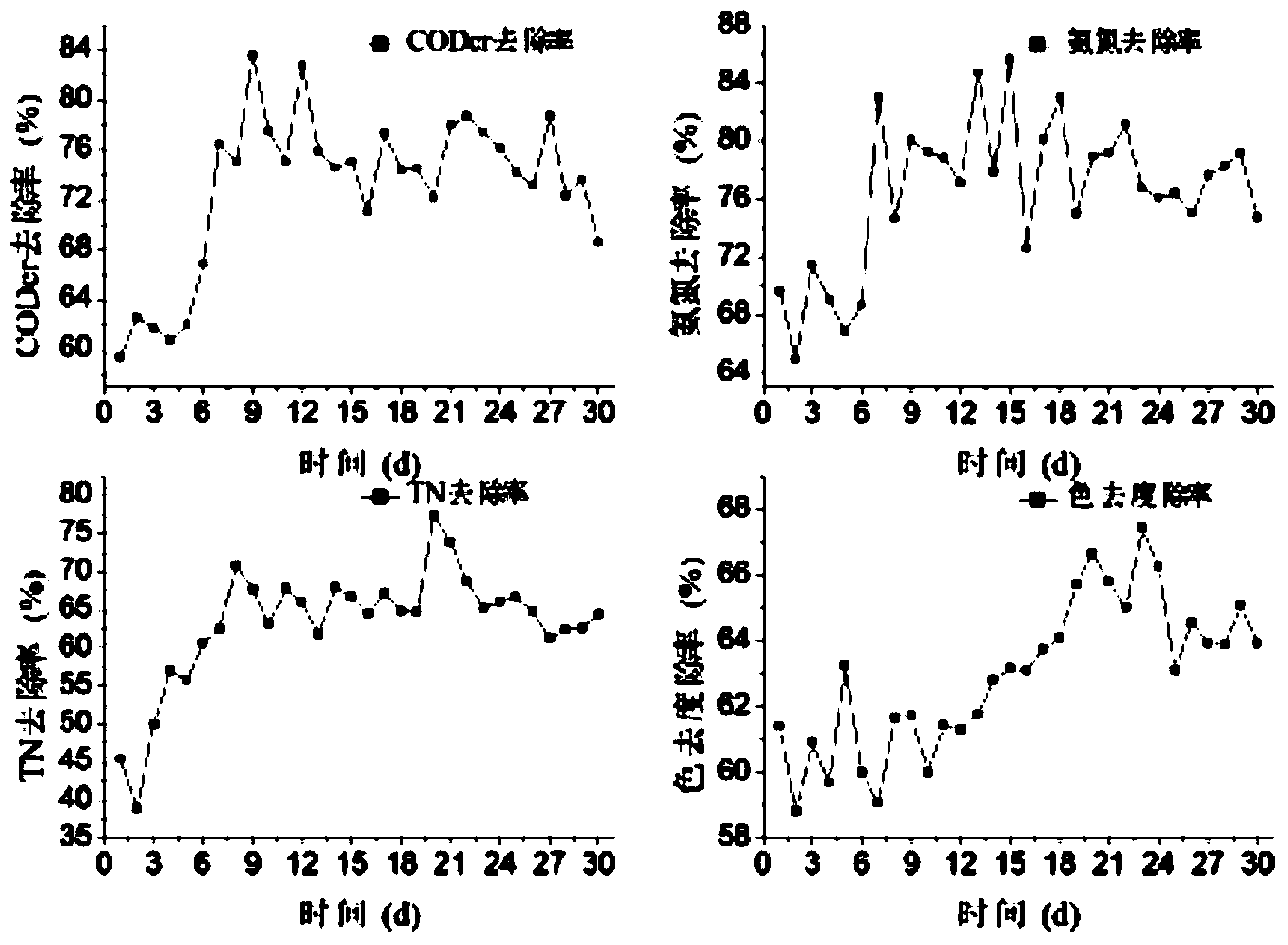

[0034] The water quality of the wastewater discharged from each dyeing process section of the dyeing workshop is tracked and monitored. Due to the dyeing of dark and light-colored yarns, the specific operating procedures are not the same. Now it is divided into beige (light color) and dark blue (dark color) to analyze the specific water quality.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com