An improvement of a tractor planetary end drive

A technology of tractors and planets, applied in the direction of transmission, transmission parts, gear transmission, etc., can solve problems such as uneven load, and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

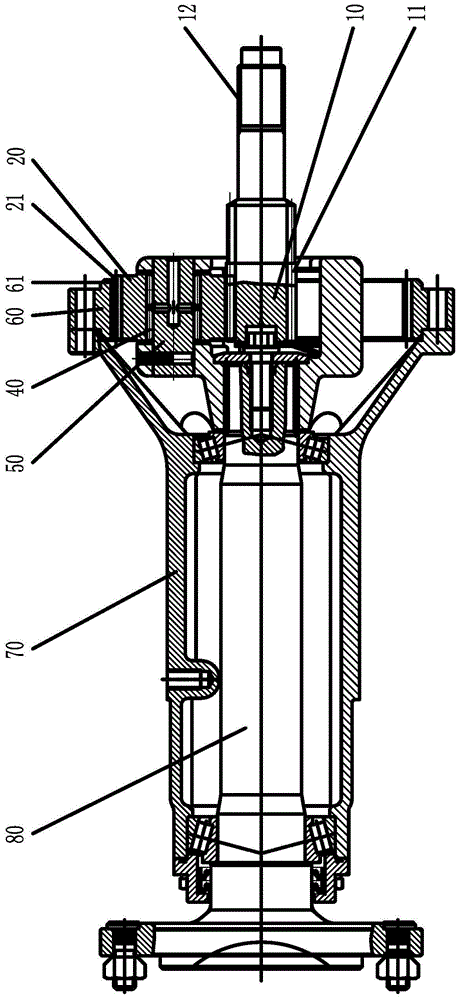

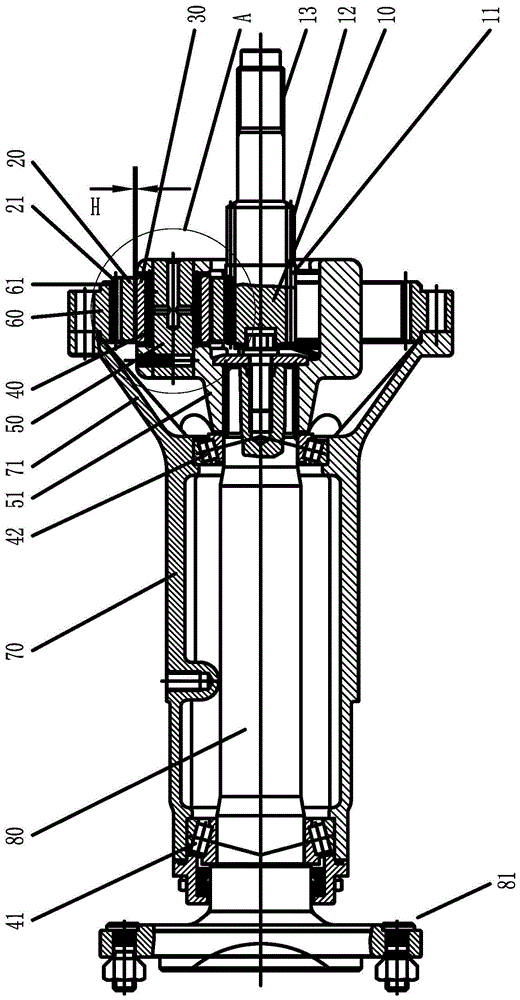

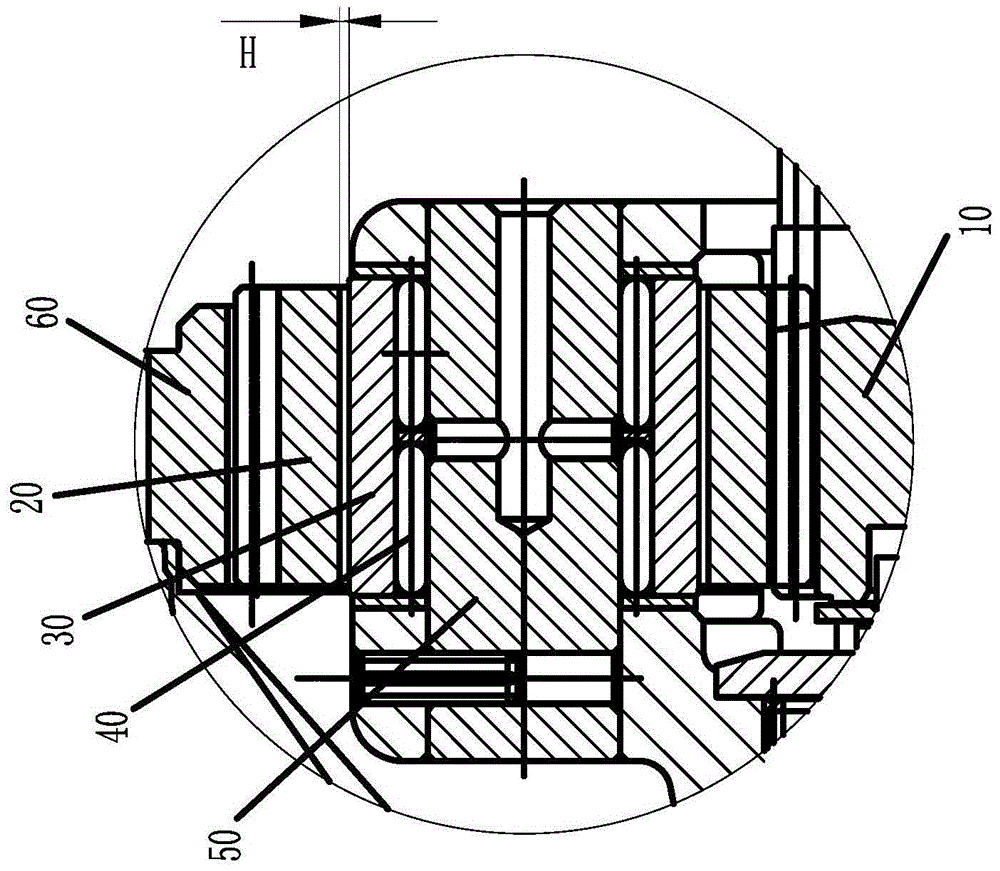

[0018] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 2 — Figure 4 :

[0019] An improvement of a tractor planetary end drive, including an output shaft 80 and a drive shaft 10 arranged on coaxial lines, a shaft sleeve 70 is set on the output shaft 80, a sun gear 11 is set at one end of the drive shaft 10, and a The planetary gear 20 which meshes with the sun gear 11 is installed on the planetary shaft 50, and the ring gear 60 with internal teeth 61 provided on the bushing 70 is engaged with the external teeth 21 of the planetary gear 20 for transmission. A bearing 40 and an intermediate ring 30 are sequentially fitted between the planetary wheel shaft 50 and the planetary wheel 20 from inside to outside, and a radial floating gap H is provided between the planetary wheel 20 and the intermediate ring 30 .

[0020] The above planetary shaft 50 and the bearings 40 , the intermediate ring 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com