Gears and Transmission Mechanisms

A technology of gears and rims, which is applied in the field of gears and transmission mechanisms, can solve problems such as the inability to ensure uniform load on the tooth surface under working conditions, increase the amount of grinding modification, and reduce the hardness of the tooth surface, so as to reduce the amount of design modification and improve The strength and life of gears, and the effect of ensuring load balancing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

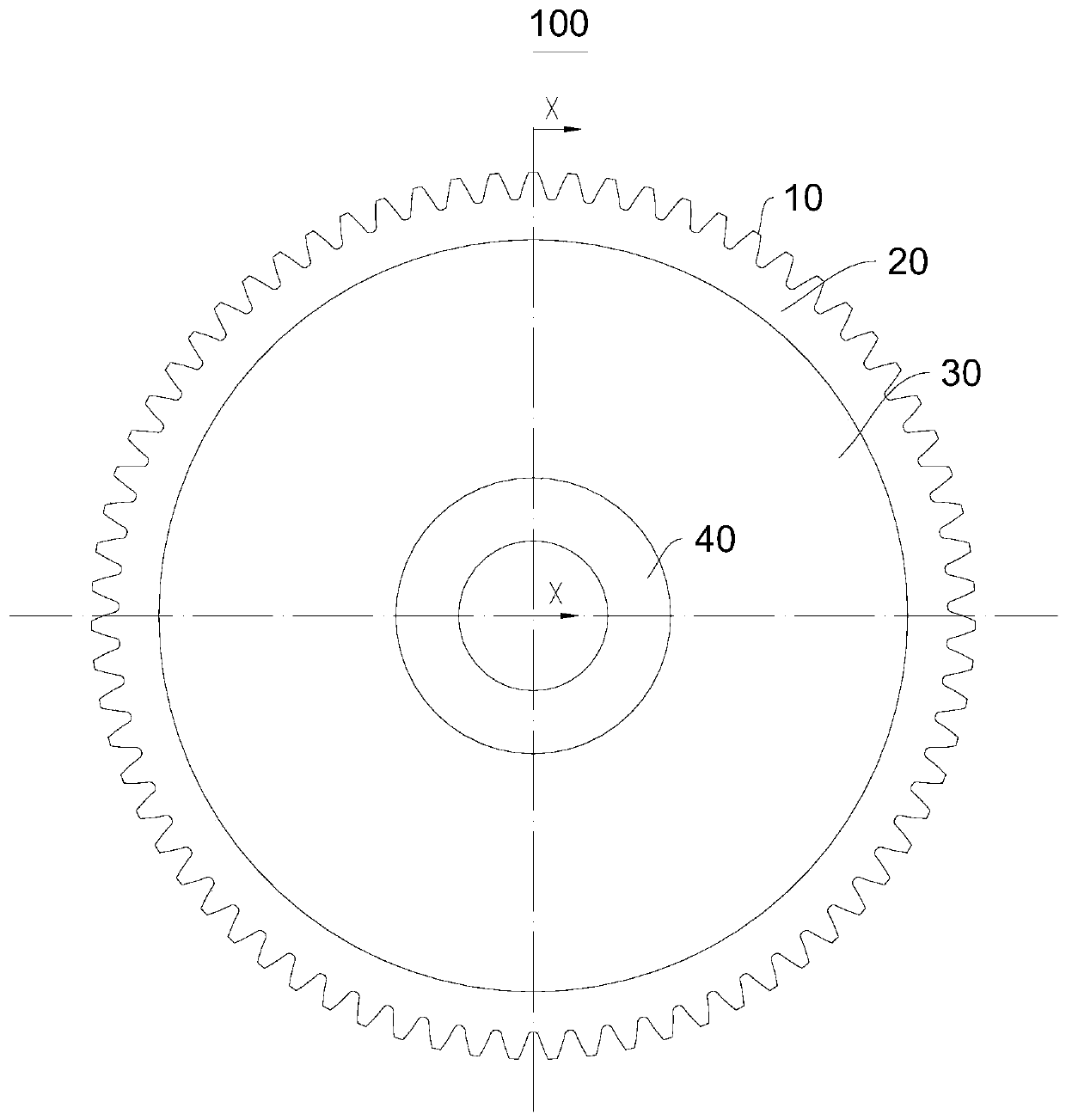

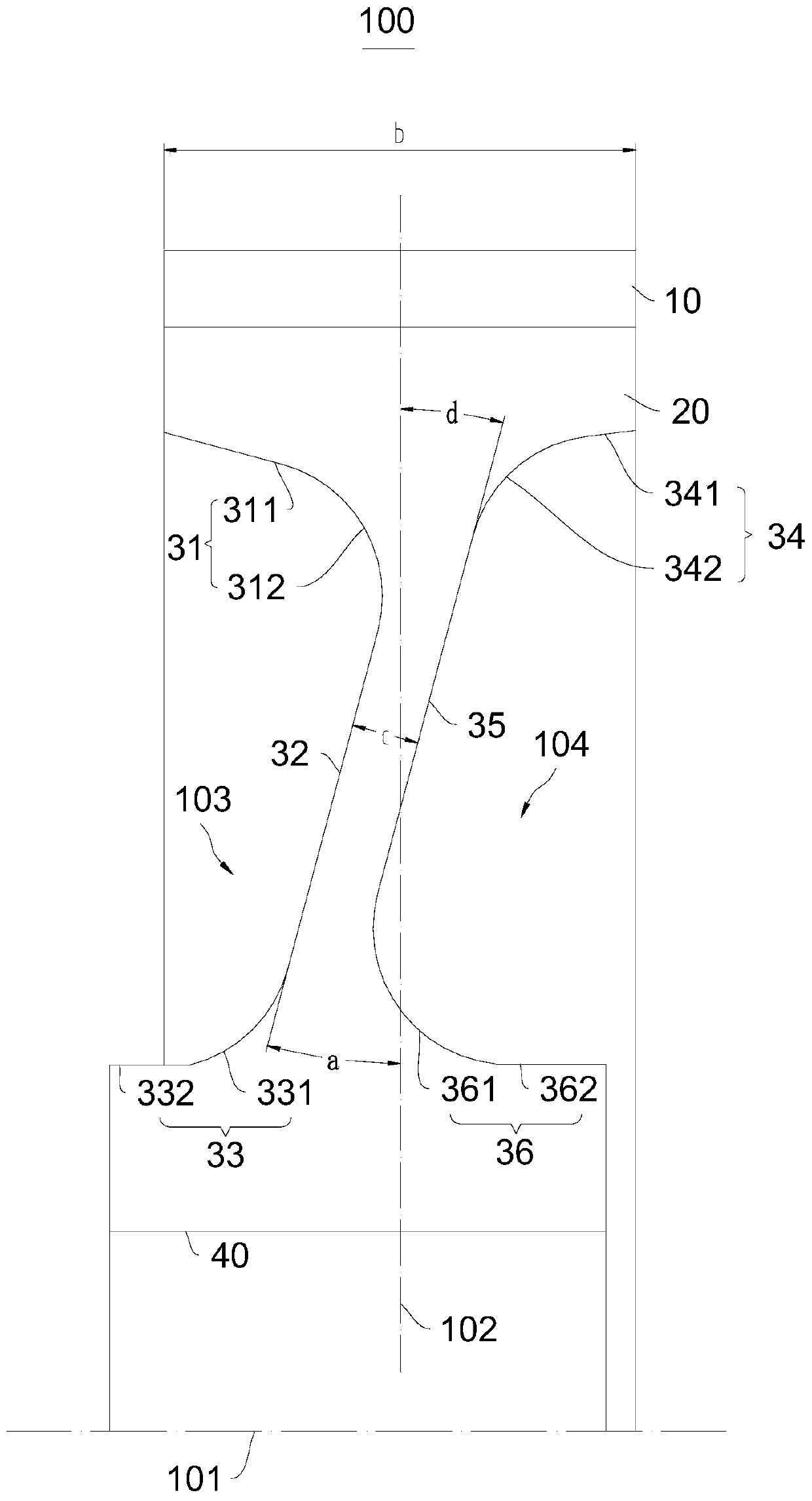

[0037] Please refer to figure 1 and figure 2 , the present embodiment provides a gear 100, which includes sequentially connected gear teeth 10, rim 20, web 30 and hub 40, with the plane perpendicular to the rotational axis 101 of the gear 100 as the reference plane 102, the web The plate 30 is inclined relative to the reference plane 102 .

[0038] The gear teeth 10, the wheel rim 20, the web 30 and the wheel hub 40 are fixedly connected or integrally formed.

[0039] The web 30 is arranged obliquely, and the web 30 of the gear 100 can be deformed under a load so as to have a certain degree of flexibility.

[0040] When the gear 100 is meshed and loaded, the web 30 can be deformed under force, reducing the amount of meshing misalignment of the gear 100, thereby reducing the amount of modification designed for the gear 100. Since the deformation of the flexible web 30 is related to the load of the working condition, that is, the load The greater the displacement, the greate...

Embodiment 2

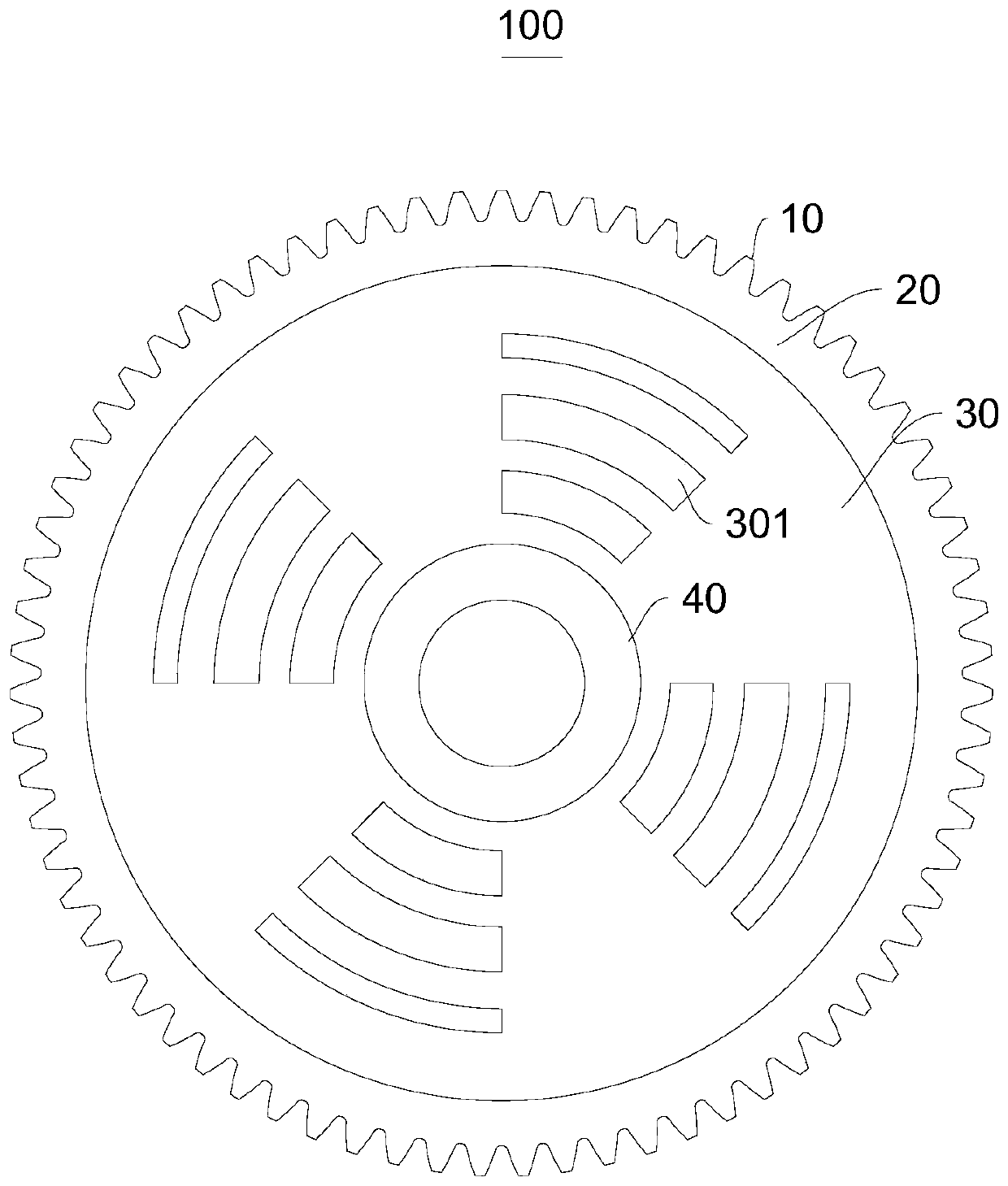

[0094] Please refer to image 3 , this embodiment also provides a gear 100, the technical solution described in embodiment 1 is also applicable to this embodiment, and the disclosed technical solution in embodiment 1 will not be described again.

[0095] Specifically, the difference between this embodiment and Embodiment 1 is that the web 30 is provided with a plurality of through-hole groups, each through-hole group includes a plurality of through-holes 301, and the opening of the through-holes 301 is arc-shaped, and each through-hole A plurality of through holes 301 in the group are sequentially distributed in the direction from the hub 40 to the rim 20, the central angles corresponding to the plurality of through holes 301 in each through hole group are the same, and the plurality of through holes in each through hole group Through hole 301 is on the direction from wheel hub 40 to rim 20, and the width of through hole 301 gradually reduces, and in each through hole group, t...

Embodiment 3

[0104] This embodiment also provides a transmission mechanism, which includes the aforementioned gear 100 and has all the functions of the gear 100 .

[0105] The structure of the gear 100 can refer to Embodiment 1 or 2.

[0106] The transmission mechanism can use one of the above-mentioned gears 100, or two or more of the above-mentioned gears 100 can be selected.

[0107] The transmission mechanism has a better use effect under the conditions of heavy load, variable working conditions, and large meshing misalignment of the paired gears.

[0108] To sum up, the present invention provides a gear 100, which can deform under load, reduce the meshing misalignment and misalignment difference in each working condition, and reduce the design modification amount of the gear 100, thereby ensuring that the gear 100 The tooth surface is evenly loaded, and the strength and life of the gear 100 are improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com