Device for rapidly disassembling and assembling toilet bowl cover plate assembly

A technology of plate components and toilet lids, which is applied in the field of quick disassembly and assembly devices, and can solve problems such as increasing the difficulty of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

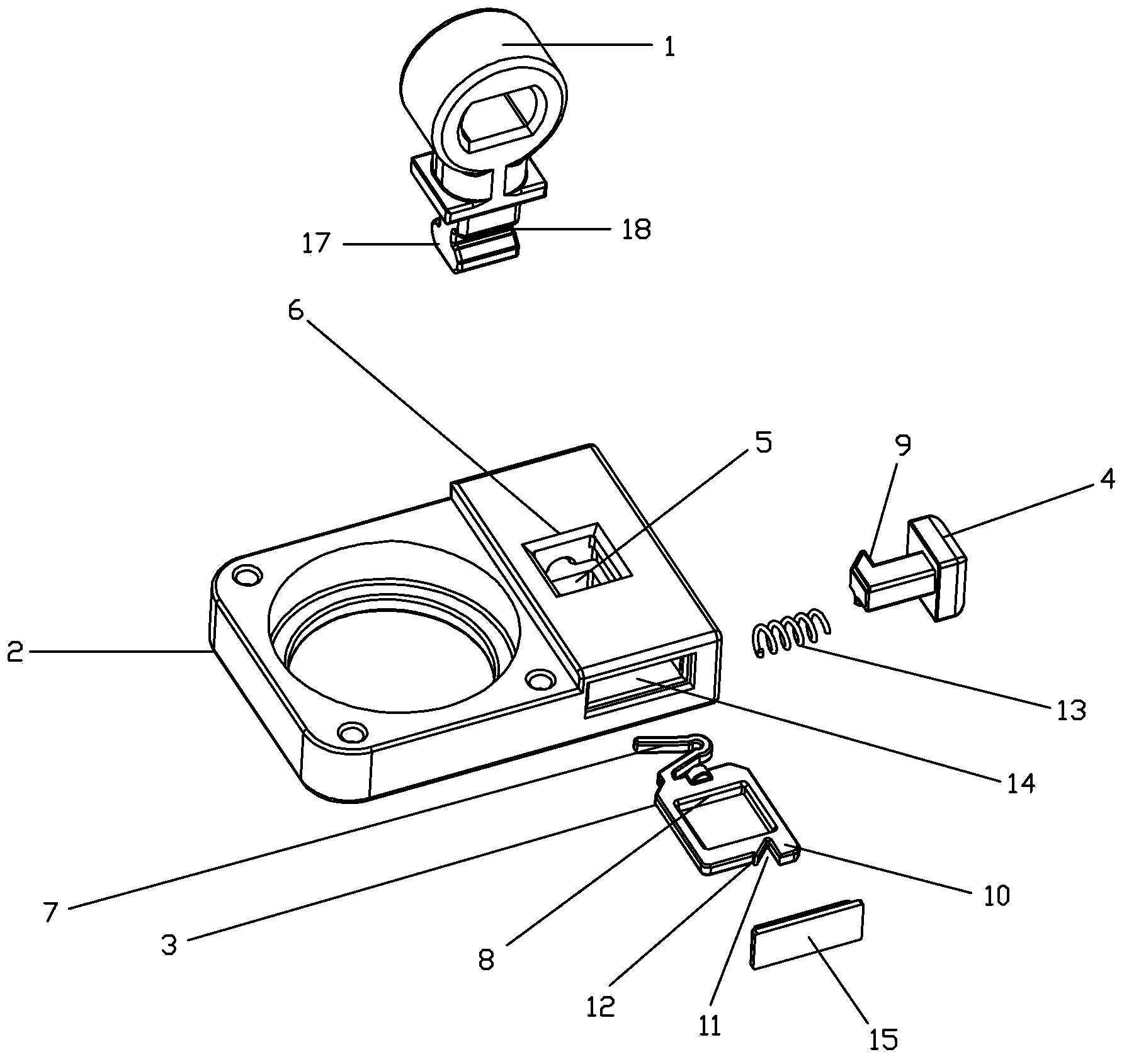

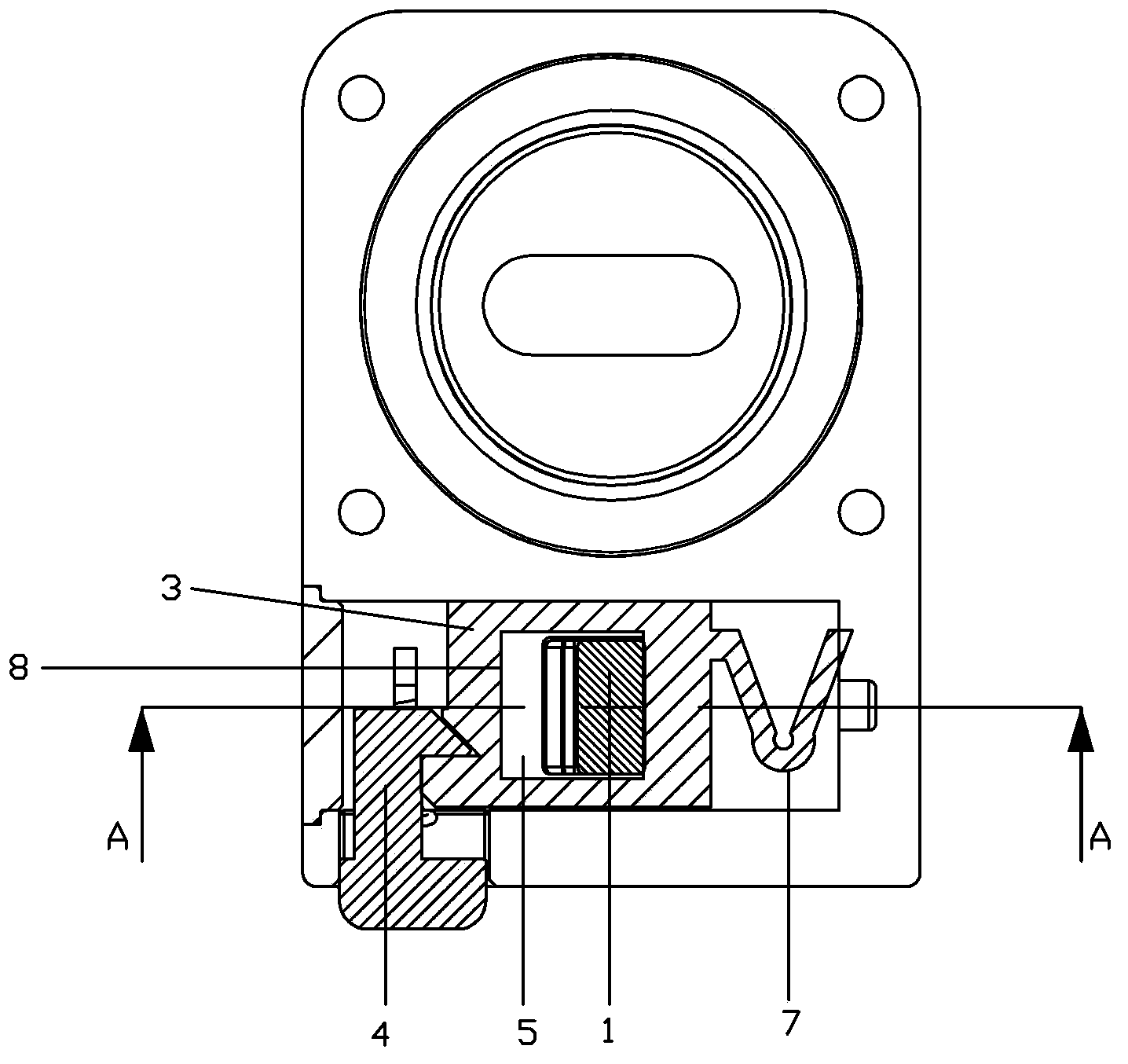

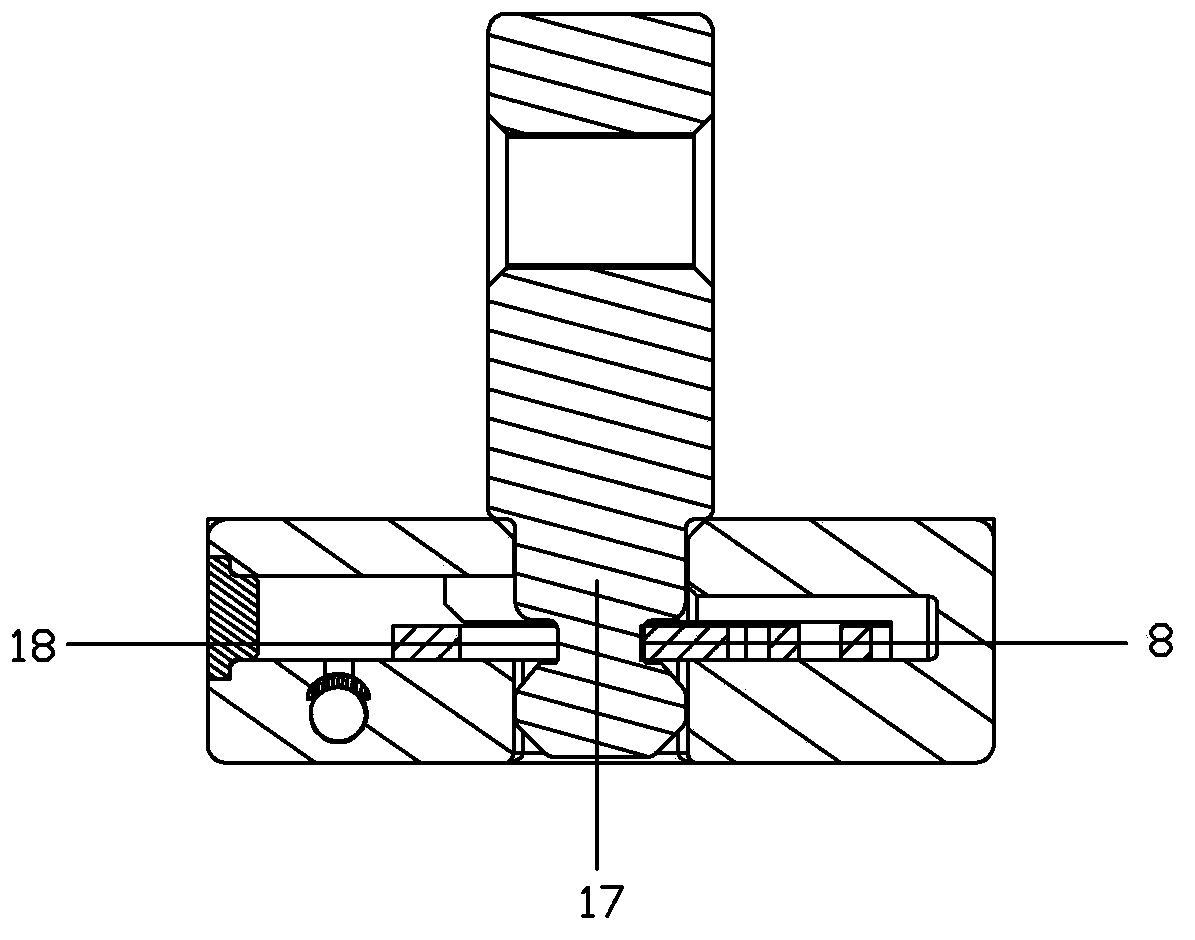

[0051] Such as figure 1As shown, a quick disassembly device for a toilet cover assembly includes a pillar 1 , a base 2 , a locking piece 3 , a switch, and a first elastic member 7 ; the switch in this embodiment is a button 4 . The base 2 is provided with an accommodating cavity 5, and the accommodating cavity 5 is provided with an insertion hole 6 on the top surface of the base 2; the locking piece 3 is installed in the accommodating cavity 5 through the first elastic member 7, and the locking piece 3 is provided with a card hole 8; the depth of the insertion hole 6 reaches below the plane of the lock piece 3; the button 4 is installed on the end of the lock piece 3 opposite to the first elastic member 7, and is used for locking the lock piece. 3 to limit and drive; the above-mentioned pillar 1 is inserted into the insertion hole 6 and fixed through the clamping hole 8 . The button 4 is installed in the accommodating chamber 5 through the second elastic member 13 , and the m...

Embodiment 2

[0071] Such as Figure 11 , Figure 12 As shown, a quick disassembly device for a toilet cover assembly includes a pillar 1, a base 2, a locking plate 3, a switch, and a decorative cover 26. The switch in this embodiment is a knob 19. The base 2 is provided with an accommodating cavity 5 , and the accommodating cavity 5 is provided with an insertion hole 6 on the top surface of the base 2 ; the depth of the insertion hole 6 reaches below the plane of the locking piece 3 . The locking plate 3 is provided with a clamping hole 8 for inserting the pillar 1 into the insertion hole 6; the clamping hole 8 may be closed or not closed, and in this embodiment, the clamping hole 8 is A U-shaped mouth that is not closed on one side. The locking piece 3 and the switch are installed in the accommodation cavity 5; the switch drives the locking piece 3 to move, and the pillar 1 is fastened and fixed through the clamping hole 8.

[0072] One end of the knob 19 has a protruding part 21; one ...

Embodiment 3

[0082] A quick disassembly and assembly device for a toilet cover assembly, comprising a pillar 1, a base 2, and a locking piece 3, the base 2 is provided with a housing chamber 5, and the housing chamber 5 is provided with an insertion hole on the top surface of the base 2 6. It is used to insert the pillar 1 into the insertion hole 6. One end of the lock piece 3 is the operation part, and the other end is provided with a lock hole 28. The operation part of the lock piece 3 extends out of the base 2, and the lock hole 28 is installed In the accommodating chamber 5 of the base 2, it is used to clamp or release the pillar.

[0083] In the present embodiment, the locking plate 3 is a knob, the operating part at one end of the knob is a driving lever 22, the other end is a locking lever 29, and the locking hole 28 is an unclosed locking opening arranged on the locking lever 29; The rod 22 can drive the knob to rotate, and then drive the lock rod 29 to move; the base 2 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com