Preparation method of textile hot-melt size for polyester-cotton

A textile heating and melting technology, applied in textiles and papermaking, fiber type, fiber treatment, etc., can solve the problems of high temperature and high viscosity, achieve fast sizing speed, save energy consumption, and improve production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

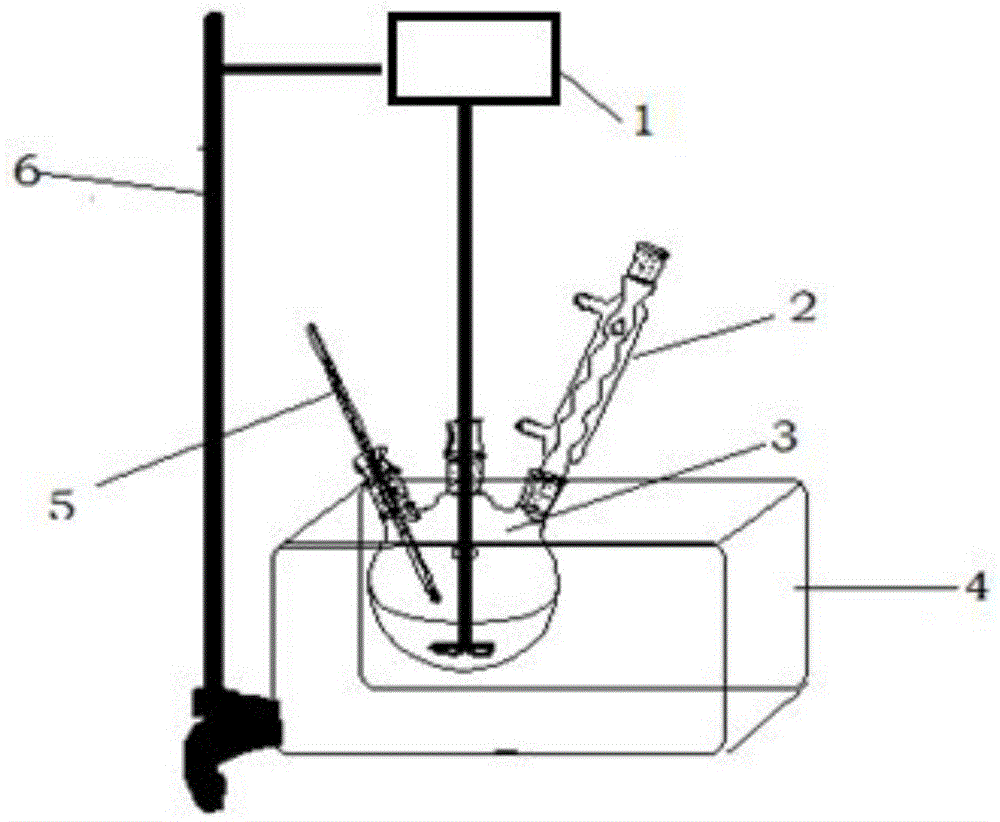

[0038] The preparation device adopted in the preparation method of polyester-cotton textile hot-melt size of the present invention, its structure is as follows figure 1 As shown, the iron frame platform 6 is included, and the iron frame platform 6 is composed of a vertically arranged first support rod and a horizontally arranged second support rod, the upper end of the first support rod is connected with the second support rod, and the second support rod is connected There is an electric stirrer 1, and the stirring rod of the electric stirrer 1 vertically extends into the three-necked flask 3 through one mouth of the three-necked flask 3, and the other two bottlenecks of the three-necked flask 3 are respectively connected with a spherical condenser tube 2, a thermometer 5, and a three-necked flask. The flask 3 is placed in a constant temperature water bath 4.

[0039] The preparation method of polyester-cotton textile hot-melt size material of the present invention, concretely...

Embodiment 1

[0054] Weigh maleic anhydride, vinyl acetate, methyl methacrylate, and acrylamide respectively according to the ratio of substances of 0.8:0.7:0.7:1.2; wherein, maleic anhydride 0.08mol (7.06g), acetic acid Vinyl ester 0.07mol (6.69g), methyl methacrylate 0.07mol (7.00g), acrylamide 0.12mol (8.52g), the maleic anhydride, vinyl acetate, methyl methacrylate, Add acrylamide into a three-necked flask, insert the stirring rod of the electric stirrer into one mouth of the three-necked flask, then insert a thermometer and a spherical condenser into the other two necks of the three-necked flask, and finally place the three-necked flask at a constant temperature In the water bath; the condensed water is passed through the spherical condenser tube, and the temperature of the constant temperature water bath is adjusted to 70°C. During this period, the actual temperature in the three-necked flask is constantly monitored by a thermometer; when the temperature of the constant temperature wat...

Embodiment 2

[0057] Weigh maleic anhydride, vinyl acetate, methyl methacrylate, and acrylamide respectively according to the ratio of substances of 1:0.9:0.9:1.5; among them, 0.1mol (8.82g) of maleic anhydride, acetic acid Vinyl ester 0.09mol (8.60g), methyl methacrylate 0.09mol (9.00g), acrylamide 0.15mol (10.65g), the maleic anhydride, vinyl acetate, methyl methacrylate, Add acrylamide into a three-necked flask, insert the stirring rod of the electric stirrer into one mouth of the three-necked flask, then insert a thermometer and a spherical condenser into the other two necks of the three-necked flask, and finally place the three-necked flask at a constant temperature In the water bath; the condensed water is passed through the spherical condenser tube, and the temperature of the constant temperature water bath is adjusted to 75°C. During this period, the actual temperature in the three-necked flask is constantly monitored by a thermometer; when the temperature of the constant temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com