Self-locking rail connection part

A connecting part and self-locking technology, which is applied in the field of self-locking fence connecting parts, can solve the problems that the overall protection performance of the fence is difficult to be guaranteed, the fence is difficult to recycle, and the connection strength is not enough, so as to achieve the improvement of firmness and stability, Avoid damage and increase the overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

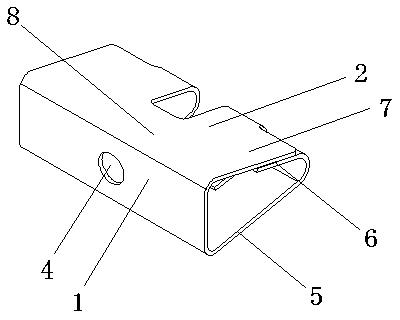

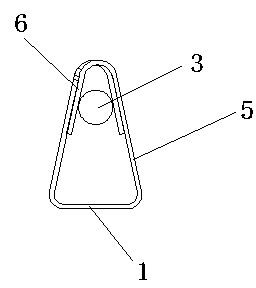

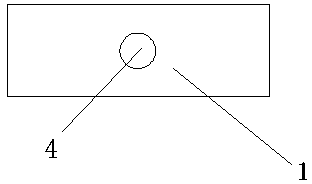

[0027] like figure 1 , figure 2 and image 3A self-locking fence connecting part is shown, which includes a position determining part, and a fence fixing part connected with the position determining part. The position determination part is composed of a position determination end 1 that includes a connecting device, and the connection device is a threaded connection hole 4 that is arranged at the center of the position determination end 1; the fence fixing part includes a plurality of position determination ends. 1 extended fence fixed end; the contact mode between multiple fence fixed ends and the fence 3 adopts line contact; the fence fixed end is composed of two pairs of fence self-locking fixed ends 2, and the same pair of fence self-locking fixed ends The contact lines between the two fence self-locking fixed ends 2 and the fence 3 in 2 are respectively located on both sides of the vertical plane passing through the fence axis and perpendicular to the position determin...

Embodiment 2

[0043] As a further improvement of the present invention, in the same pair of fence self-locking fixed ends, the contact line between one fence self-locking fixed end 2 and the fence 3, and the plane of the fence axis are the same as the plane passing through the same pair of fence self-locking fixed ends. The contact line between the self-locking fixed end 2 of a fence and the fence 3 and the plane of the fence axis form an included angle range of 170°. With the above-mentioned design, it makes the contact line between the two self-locking fixed ends of the fence and the fence, and the axis of the fence almost in the same plane, so that the bearing of the fence in the connecting part of the fence The supporting force can be basically kept balanced, thereby realizing the improvement of its connection stability.

[0044] The remaining features and advantages of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com