Parallel cross-connection communication pipe fitting

A cross-connection, parallel technology, applied in the direction of pipes/pipe joints/fittings, pipe elements, pipes, etc., can solve the problems of inconvenient setting of bridge bends, damage to the ground structure and waterproof layer, etc., to achieve a single structure and increase safety. The effect of performance, design science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

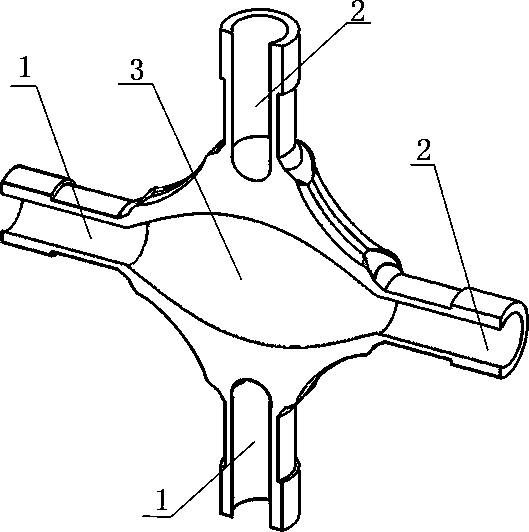

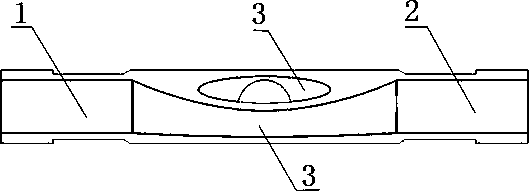

[0013] Embodiment 1: A parallel cross-connection conduit fitting, including inlet 1 and outlet 2, inlet 1 and outlet 2 are respectively connected to pipelines, inlet 1 and outlet 2 are set in a one-to-one correspondence, and the connection conduit fitting is set inside There is a conduction layer 3, and the inlet 1 and the outlet 2 are connected through the conduction layer 3. There are two sets of inlet 1 and outlet 2, two layers of conduction layer 3, arranged in parallel, respectively connected with each set of inlet 1 and outlet 2, and the adjacent two layers of conduction layer 3 are arranged in cross conduction. The internal height of the conduction layer 3 is smaller than the inner diameter of the pipe, and the width is greater than the inner diameter of the pipe. The cross-sectional area of the conduction layer 3 is equal to the cross-sectional area of the inner diameter of the pipe, so as to ensure that the flow rate of the liquid or gas entering the conduction lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com