Method for monitoring durability of electronic belt scale

An electronic belt scale and durability technology, which is applied in the field of electronic belt scale durability monitoring, can solve the problems of time-consuming, inability to adjust measurement deviation in time, poor measurement accuracy and durability, and achieve the effect of ensuring measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

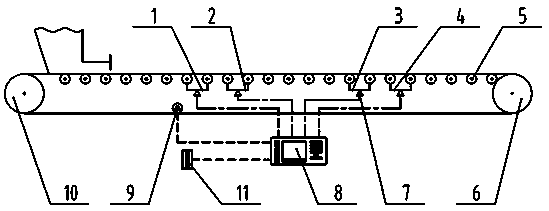

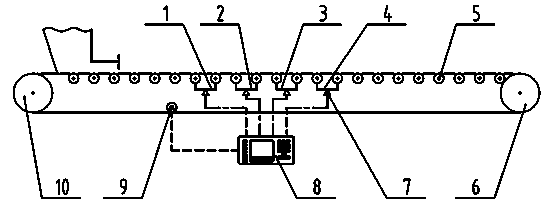

[0026] Embodiment: Test conditions: belt width: 1800mm; belt speed: 3.5 m / s; flow rate: 3800t / h

[0027] Under the operating condition of material flow rate of 3800t / h, 4 sets of independent weighing loaders measure the weight value:

[0028] Rear weighing loader 1: Material weight value 710.1kg

[0029] Rear A weighing load carrier 2: material weight value 708.5kg

[0030] Front A weighing load carrier 3: material weight value 706.9.1kg

[0031] Front weighing load carrier 4: Material weight value 705.3kg

[0032] Difference = Rear weighing loader 1 - Front weighing loader 4 = 710.1-705.3 = 4.8kg

[0033] Difference rate=4.8 / 710.1=0.67%, at this time the number of span calibration is A.

[0034] When the external environment changes, the belt scale instrument 8 detects that the difference rate exceeds B% of the obtained difference rate, and the belt scale instrument 8 uses B% to correct the range calibration number A to obtain the corrected range calibration n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com