A Stamping Automatic Line Turnover Mechanism

A flipping mechanism and automatic line technology, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve problems such as high coordination of actions and parts of the mechanism, complicated circuit control, and restrictions on the efficiency of the production line, etc., to achieve structural Streamlined, perfect action, accurate flipping process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

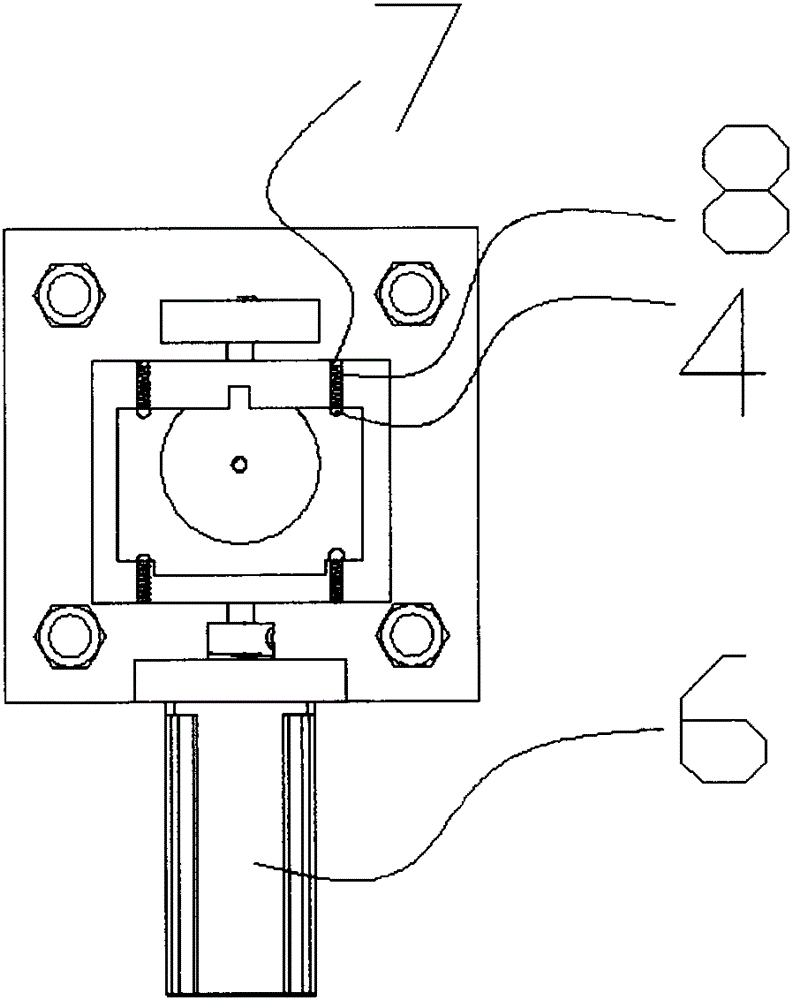

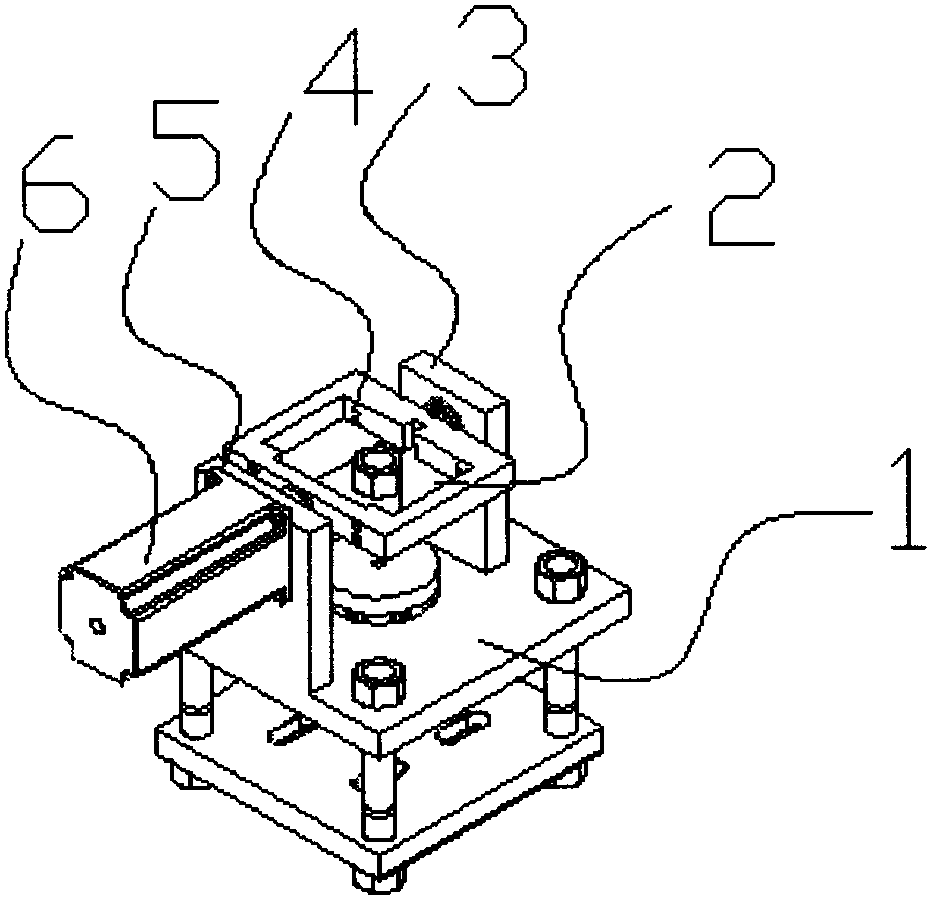

[0017] Such as figure 1 , 2 As shown, a stamping automatic line turning mechanism includes a body 1. A fixed plate 3 and a motor plate 5 are installed on the body 1. A rotating frame 2 is placed between the fixed plate 3 and the motor plate 5. The rotating frame 2 and the fixed plate 3 Through bolt connection, the rotating frame 2 and the motor plate 5 are connected by a motor 6 mounted on the motor plate 5. The motor 6 is connected to the PLC system. The rotating frame 2 is provided with a mold cavity 8 in which a limit mechanism is placed , The limit mechanism includes a spring 7 and a ball 4, the spring 7 is installed in the mold cavity 8, and the ball 4 is installed at the top of the spring 7. There are 4 groups of the limit mechanism, and each group of limit mechanisms includes 2 limit mechanisms, The two limit mechanisms are vertically arranged side by side, and the motor 6 is a stepping motor.

[0018] When the vacuum sucker puts the product into the rotating frame 2, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com