A Method of On-line Identifying Deviated State of Incident Laser

A state, laser technology, applied in laser welding equipment, welding equipment, metal processing and other directions, can solve the problems of limited application, high price, weakening the mechanical properties of sandwich structures, etc., to achieve the effect of wide application and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below the embodiment of the present invention is described in detail, present embodiment implements under the premise of technical solution of the present invention, has provided detailed embodiment and specific operation process, but protection scope of the present invention is not limited to following embodiment.

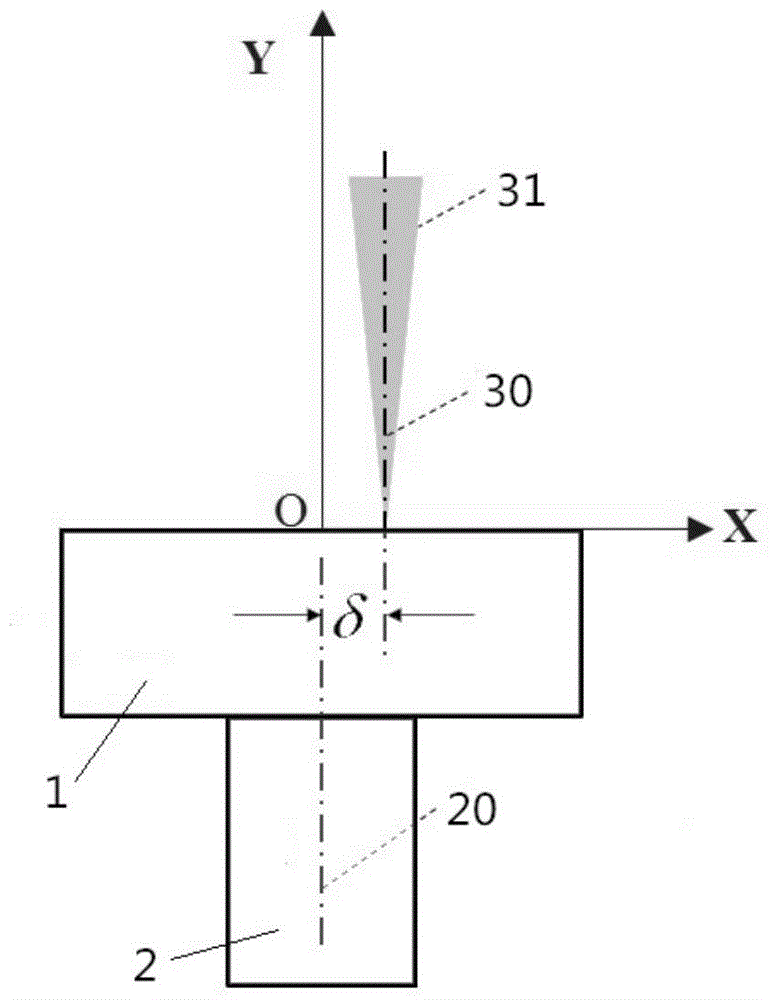

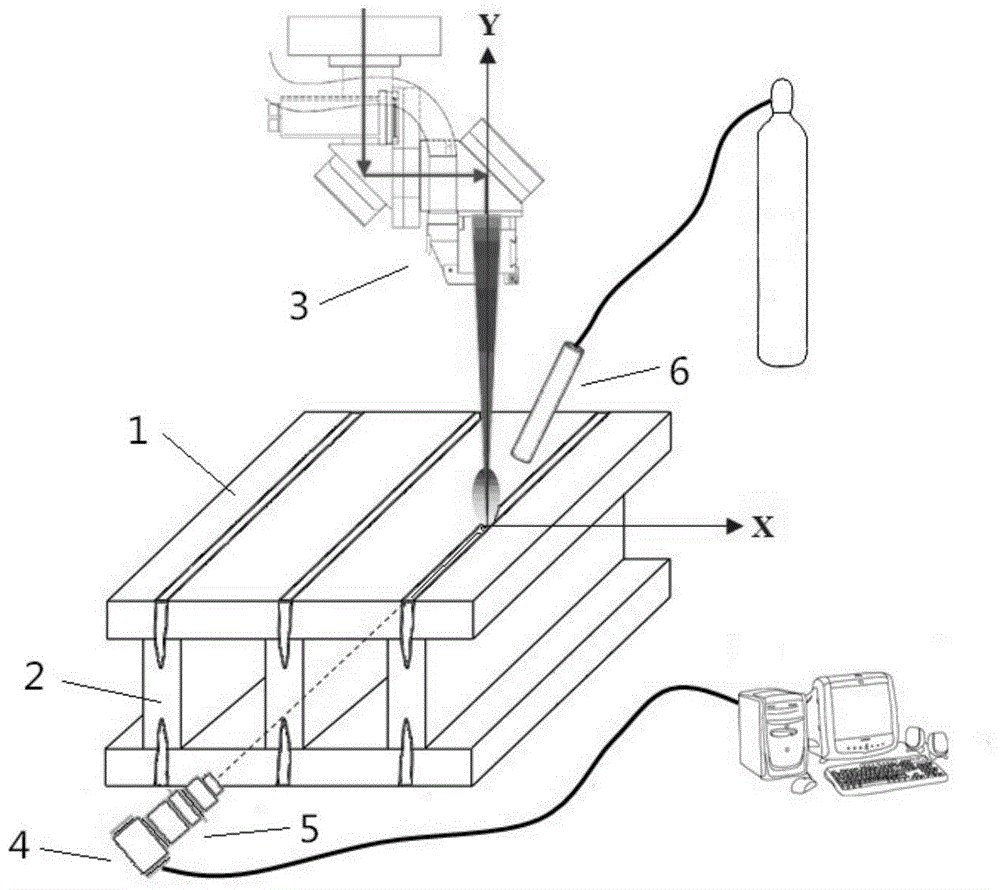

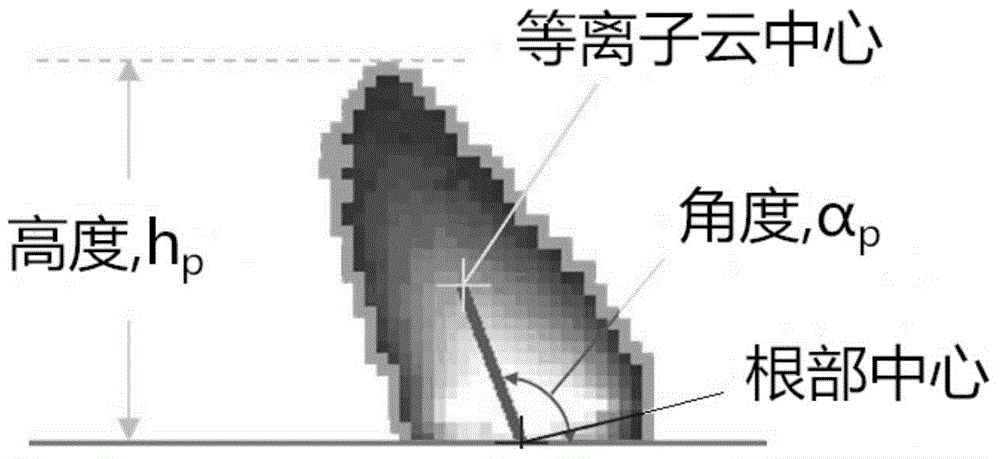

[0034] The invention discloses a method for on-line identifying the deviation state of incident laser light, which is used for carbon dioxide laser welding of metal plates with sandwich structure. like figure 1 As shown, X represents the abscissa, and Y represents the ordinate. The incident laser 31 is emitted from the laser working head and projected onto the panel 1. The so-called deviation state refers to the distance δ between the incident laser centerline 30 and the core plate centerline 20. In the process of high-power carbon dioxide laser welding, if the deviation exceeds a certain range, the connection strength between the face plate 1 and the core ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com