Electric wrench

A technology of electric wrench and swinging parts, which is applied in the direction of wrench, motor tool, wrench, etc. It can solve the problems of inconvenient operation, too long bolts, and unusability, etc., and achieve the effect of simple and convenient operation, high work efficiency and low work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

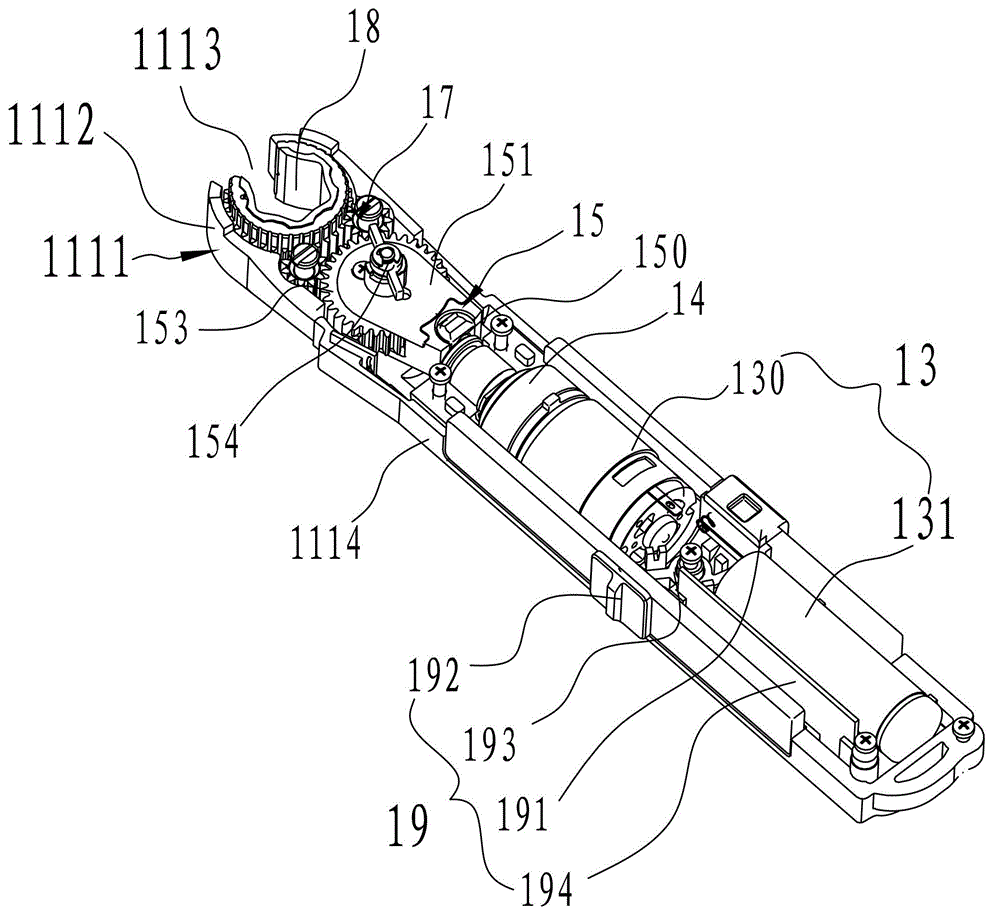

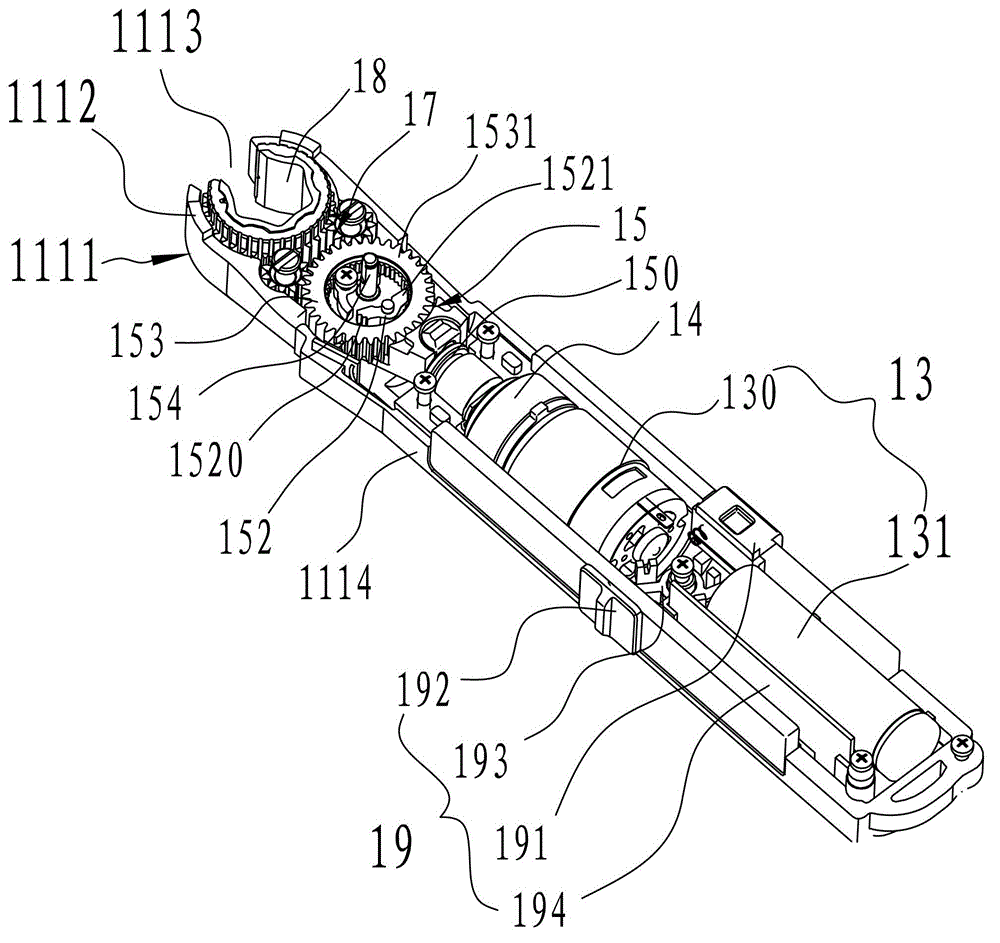

[0029] In order to better understand the technical content of the present invention, specific embodiments are given and described as follows in conjunction with the accompanying drawings.

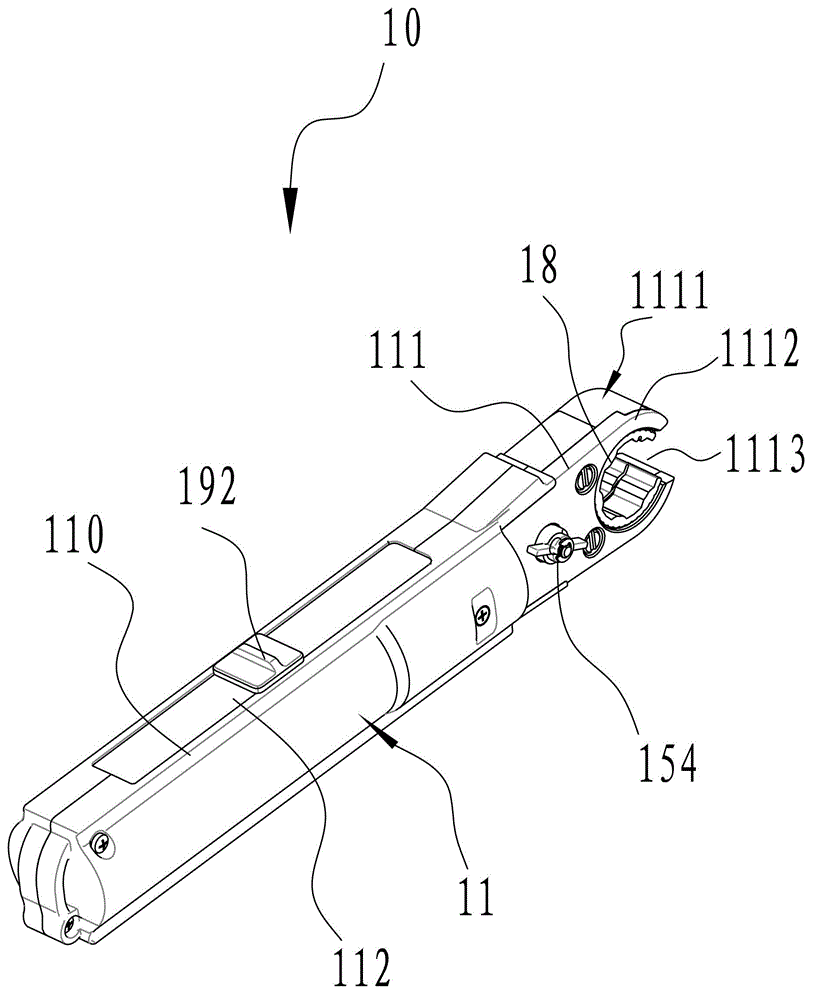

[0030] Please refer to Figure 1~3 , an electric wrench 10, including a housing 11, a power component 13, a reduction mechanism 14, a ratchet mechanism 15, a support transmission assembly 17, an open gear 18 and a control assembly 19.

[0031] The casing 11 is a "one"-shaped structure, which includes a main casing 110 extending in the longitudinal direction and a supporting casing 111 extending from one end of the main casing 110 . The power component 13 , the speed reduction mechanism 14 , the ratchet mechanism 15 , the supporting transmission assembly 17 and the split gear 18 are sequentially connected and housed in the housing 11 .

[0032] Please also refer to Figure 4 , in this embodiment, the main housing 110 includes a first outer housing 1101 and a second outer housing 1102, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com