Optimization method for plastic injection molding technological parameter

A technology for process parameter optimization and injection molding, which is used in electrical digital data processing, special data processing applications, instruments, etc., and can solve problems such as difficulty in accurate adjustment, large deviation, and cumbersome process parameter setting process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0149] The present invention is further described below in conjunction with embodiment.

[0150] The injection molding machine used in the experiment is FANUCS2000i150A of Japan FANUC Company, and the experimental material is POM (polyoxymethylene) plastic.

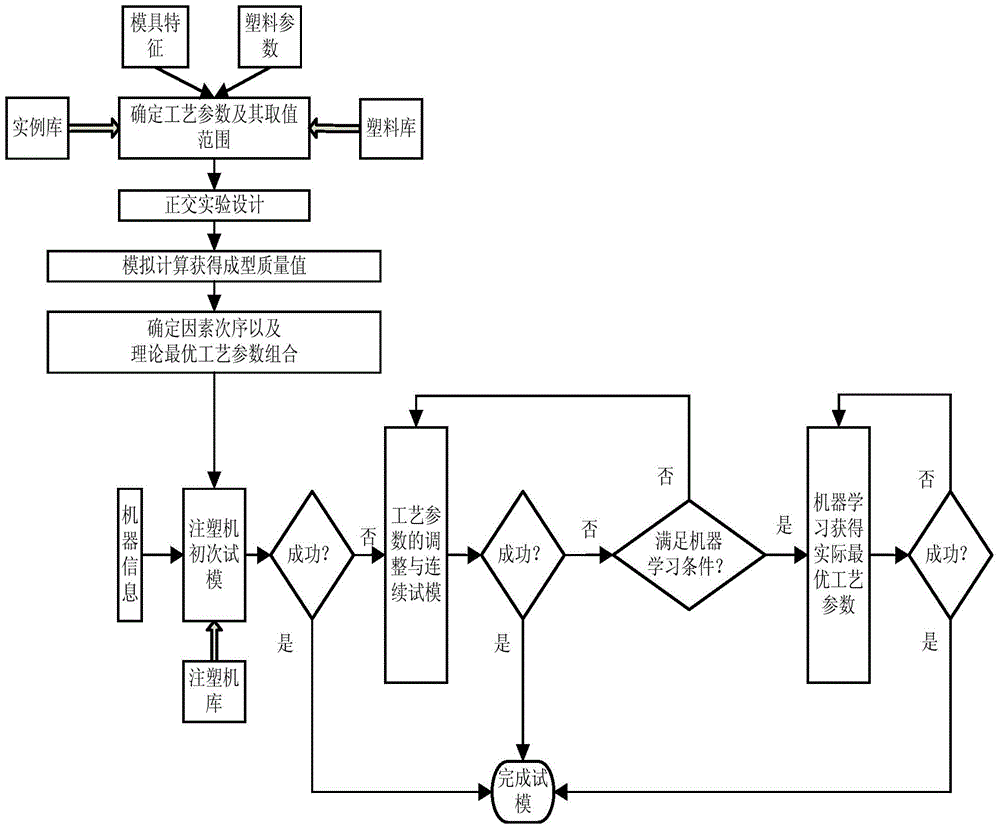

[0151] Such as figure 1 As shown, the embodiment of the present invention includes a preliminary optimization step and a re-optimization step;

[0152] (1) Preliminary optimization step, including the following sub-steps:

[0153] (1.1) Determine process parameters and their value ranges:

[0154] The process parameters include melt temperature T p , mold temperature T m , injection rate V, holding pressure P, holding time t p , cooling time t c ;

[0155] The selected plastic category: POM, grade: POM Generic Estimates, manufacturer: CMOLD Generic Estimates, according to the plastic database in the plastic injection molding CAE simulation software HSCAE can get 180 ℃ ≤ T p ≤235℃, 50℃≤T m ≤105℃;

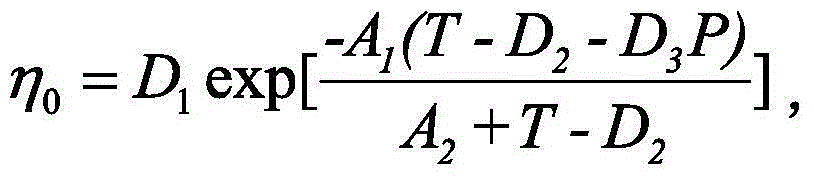

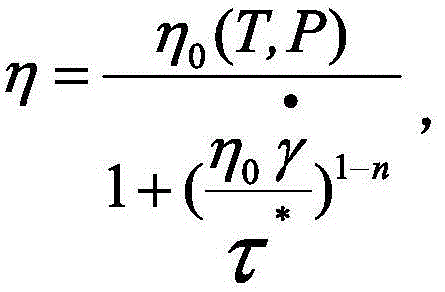

[0156] The flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com