Flame-retardant porous sheets, moldings thereof, and flame-retardant acoustical absorbents for automobiles

A fiber sheet and sound-absorbing material technology, which is applied in fiber treatment, superstructure sub-assembly, textiles and papermaking, etc., can solve the problems of weather resistance degradation, flame retardant detachment, hindering sound absorption, etc., and achieve improved mold release , Adhesion improvement, rigidity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

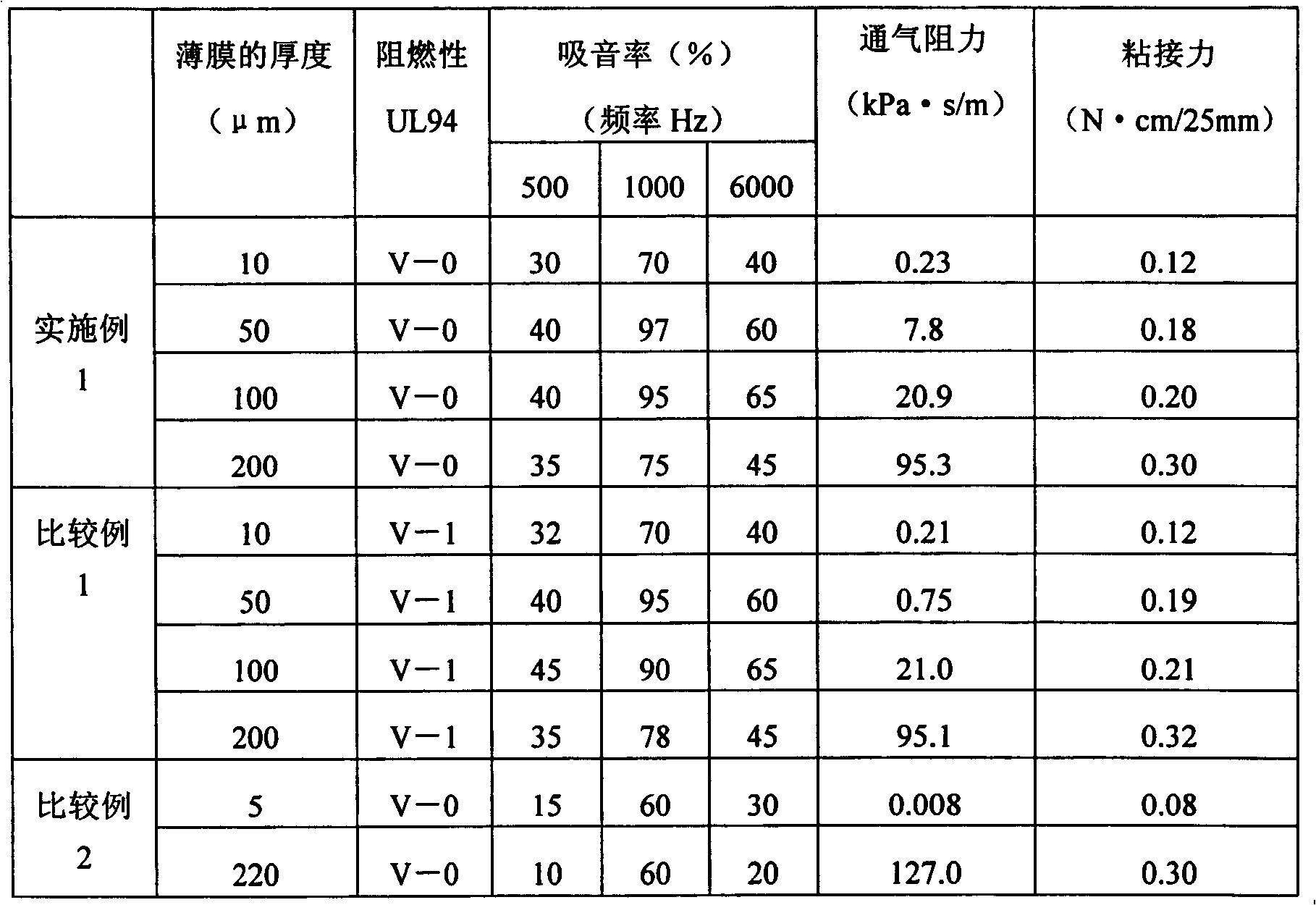

Embodiment 1

[0075] The weight per unit area composed of polyester fiber and made by spunbond method is 40g / m 2 In the non-woven fabric, an impregnating liquid is immersed in the above-mentioned non-woven fabric with a solid content of 50% by mass of the unit area weight. The impregnating liquid is added and mixed with 70 parts by mass of sulfomethylated phenol- Alkyl resorcinol-formaldehyde initial condensate (50% by mass solid content) and 30 parts by mass of melamine resin coated with ammonium polyphosphate flame retardant capsule (50% by mass aqueous dispersion, particle size: 15-20μm), dried at a temperature of 130-140°C for 5 minutes, and pre-cured the above-mentioned sulfomethylated phenol-alkylresorcinol-formaldehyde initial condensate. The flame retardant non-woven fabric fiber sheet with the flame retardant capsule bonded to the woven fabric. The obtained non-woven fiber sheet is used as the skin material, and as the base material, 15% by mass of phenol resin is used as the base mate...

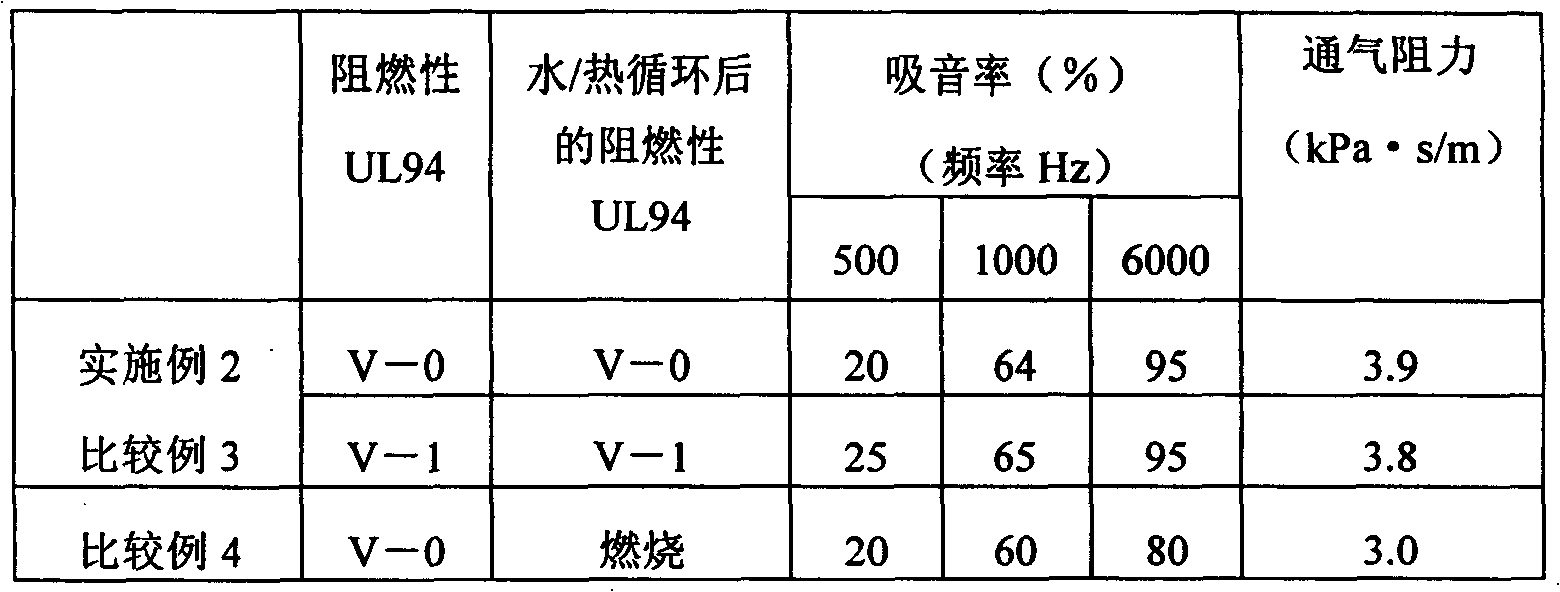

Embodiment 2

[0084] Using 60% by mass polyester fiber (fineness: 6dtex, fiber length: 25mm), 15% by mass low-melting polyester fiber (fineness: 12dtex, fiber length: 35mm) and 25% by mass kenaf fiber (fiber diameter : 0.1~0.3mm, fiber length: 35mm) composed of fiber web, and obtained sheet fiber by needle punching method (weight per unit area: 600g / m 2 , Thickness: 10mm). Then, to 80 parts by mass of the initial condensate of sulfomethylated phenol-resorcinol-formaldehyde (50% by mass solid content) was added and mixed with 20 parts by mass of a melamine resin coated ammonium polyphosphate barrier. Burning agent capsules (particle size: 10-15 μm) to prepare an immersion liquid. The impregnating liquid is used to impregnate the sheeting fiber with a solid content of 50% by mass of the unit area weight, and drying at a temperature of 100 to 130° C. for 5 minutes to pre-curing the sheeting fiber to produce Obtain flame-retardant fiber sheet. Then, the pre-cured fiber sheet was hot-pressed and pre...

Embodiment 3

[0095] The weight per unit area made of polyester fiber and made by spunbond method is 40g / m 2In the non-woven fabric, 3 parts by mass of fluorine-based water and oil repellent will be added to 40 parts by mass of sulfomethylated phenol-alkylresorcinol-formaldehyde initial condensate (60% by mass solid content) (40% by mass solid content), 1 part by mass of carbon black dispersion (30% by mass solid content), 2 parts by mass of phosphorus and nitrogen-containing flame retardant (40% by mass solid content) and 54 parts by mass of water The prepared impregnating liquid is immersed in the above non-woven fabric with a solid content of 50% by weight of the unit area weight, and then added to 80 parts by mass of water mixed with 20 parts by mass as a flame retardant capsule The dispersion liquid of "Ek リツト AP462" (trade name: manufactured by Clarion Technology Co., Ltd.) is sprayed on the surface of the non-woven fabric coated with the above-mentioned impregnating liquid at a solid con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com