Sunroof windshield mounting station tooling device

A glass and position technology technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of time and energy consumption, low production efficiency, time-consuming and labor-intensive glass components, and save time and labor in the installation process, improve production efficiency, Manpower requirement and time-consuming reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will now be described in further detail with reference to the accompanying drawings.

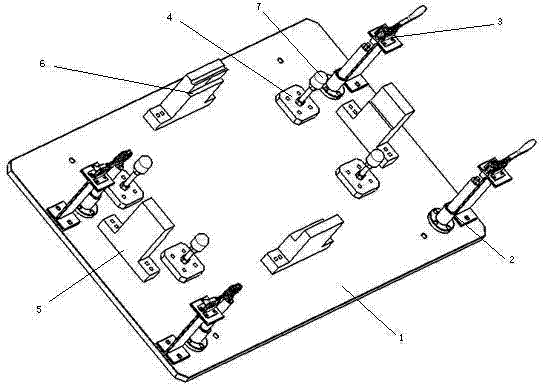

[0012] see figure 1 , The sunroof glass installation position tooling device of the present invention includes a workbench 1, and the glass bracket 4, the glass positioning block 5, the slide rail bracket 2 and the quick clamp 3 are all arranged on the workbench 1. When assembling, support the convex surface of the glass downward on the glass support 4, and the glass positioning block 5 will clamp the four sides of the glass, thereby fixing the glass. Put the slide rail assembly on the slide rail bracket 2, and pull the quick clip 3 to fix the slide rail assembly. Both the sunroof assembly and the slide rail assembly are thus fixed in place so that no support is required. In addition, when the tooling is manufactured, the positions of the glass bracket 4, the glass positioning block 5, the slide rail bracket 2, and the quick clamp 3 are all designed for the sun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com