Method for producing illusion yarn by mixing three-color roving and illusion yarn prepared by the method

A three-color, roving technology, applied in the direction of yarn, spinning machine, drafting equipment, etc., can solve the problem of unable to obtain multi-color segment color yarn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

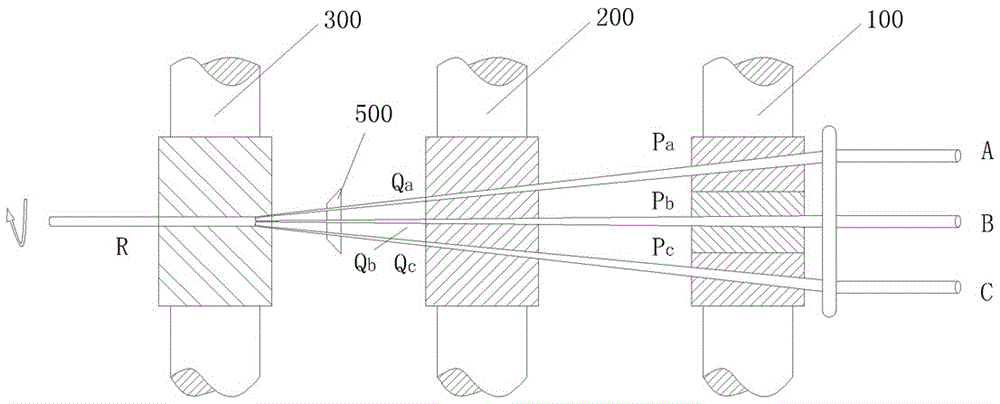

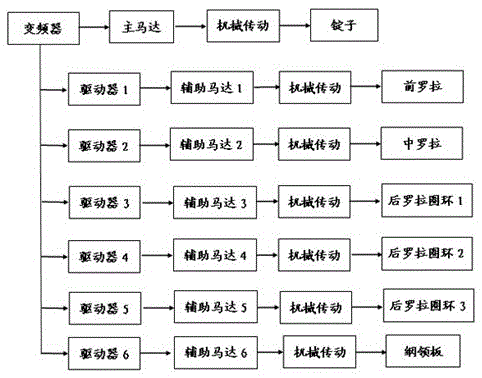

[0053] Such as figure 1 It is shown that the three-color coupling drafting and twisting device of the present invention is composed of a drafting system and a twisting system. The drafting system is composed of a rear combination roller 100, a middle roller 200 and a front roller 300, and a bell mouth 500 is arranged between the front roller and the middle roller.

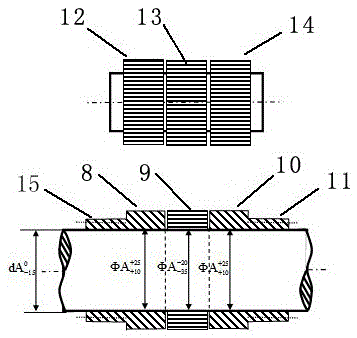

[0054] Such as figure 2 As shown, the rear combination roller 100 comprises the first ring 8, the second ring 9 and the third ring 10 equal to the outer diameter of three sections, and the first ring 8, the second ring 9 and the third ring 10 corresponds to the first top roller 12 , the second top roller 13 , and the third top roller 14 . The first ring 8 , the second ring 9 and the third ring 10 are sequentially fitted on the same mandrel, and are respectively driven by three different ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com