Integrated device for impurity removal pulping and charging of oil sludge

A technology for pulping and oil sludge, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as inability to integrate feeding materials, inability to automatically clean and discharge, and increase in production costs, and achieve The effect of reducing manufacturing cost and troubleshooting rate, saving manpower, and stabilizing the mixing ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

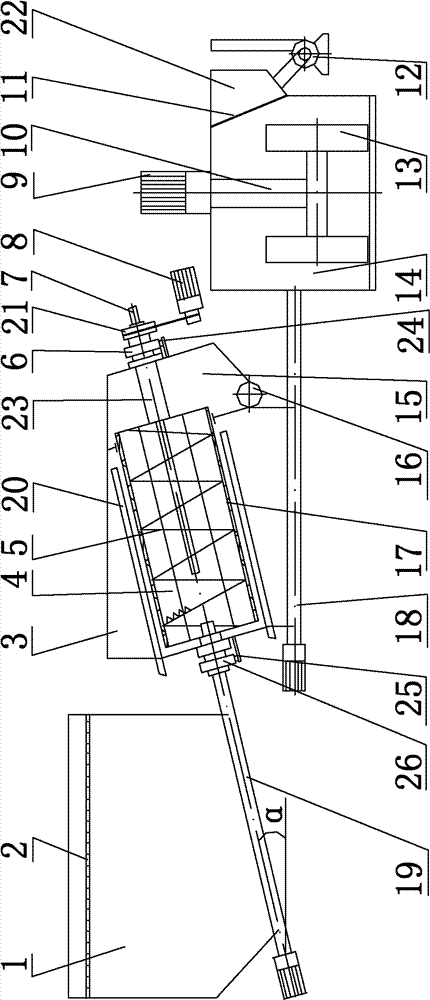

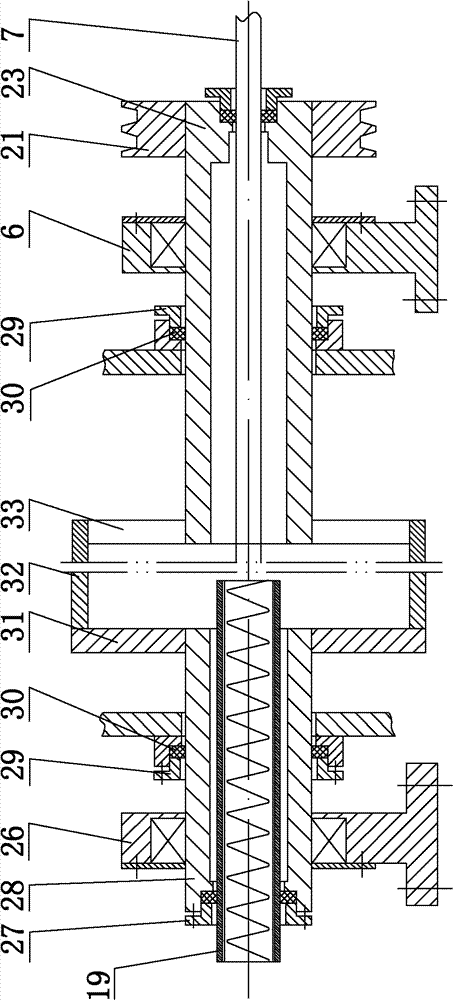

[0011] The present invention will be further described below in conjunction with accompanying drawing:

[0012] Depend on Figure 1 to Figure 2 As shown, the integrated device for sludge removal, pulping and feeding includes feed hopper 1, screw conveyor one 19, impurity removal tank 3, impurity removal drum 4, screw conveyor two 18, screw conveyor three 16, High-pressure hot water injection pipe one 7, high-pressure hot water injection pipe two 20, impurity removal drum driving mechanism 8, pulper 14, pulping driving mechanism 9, roller 13 and mud pump 12, wherein the feed hopper 1 Screw conveyor one 19 is installed at the bottom, and impurity removal drum 4 is housed in the impurity removal tank 3, and a debris pool 15 is provided, and screw conveyor three 16 is installed on the bottom of the debris pool 15, and the discharge of screw conveyor one 19 The end is located in the impurity removal drum 4, the bottom of the impurity removal tank 3 is equipped with a screw conveyo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com