Method for arranging a drive unit on a top element of a revolving door

A drive unit and revolving door technology, which is applied to revolving doors, wing leaf parts, door/window accessories, etc., and can solve the problem that installation measures cannot use revolving doors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

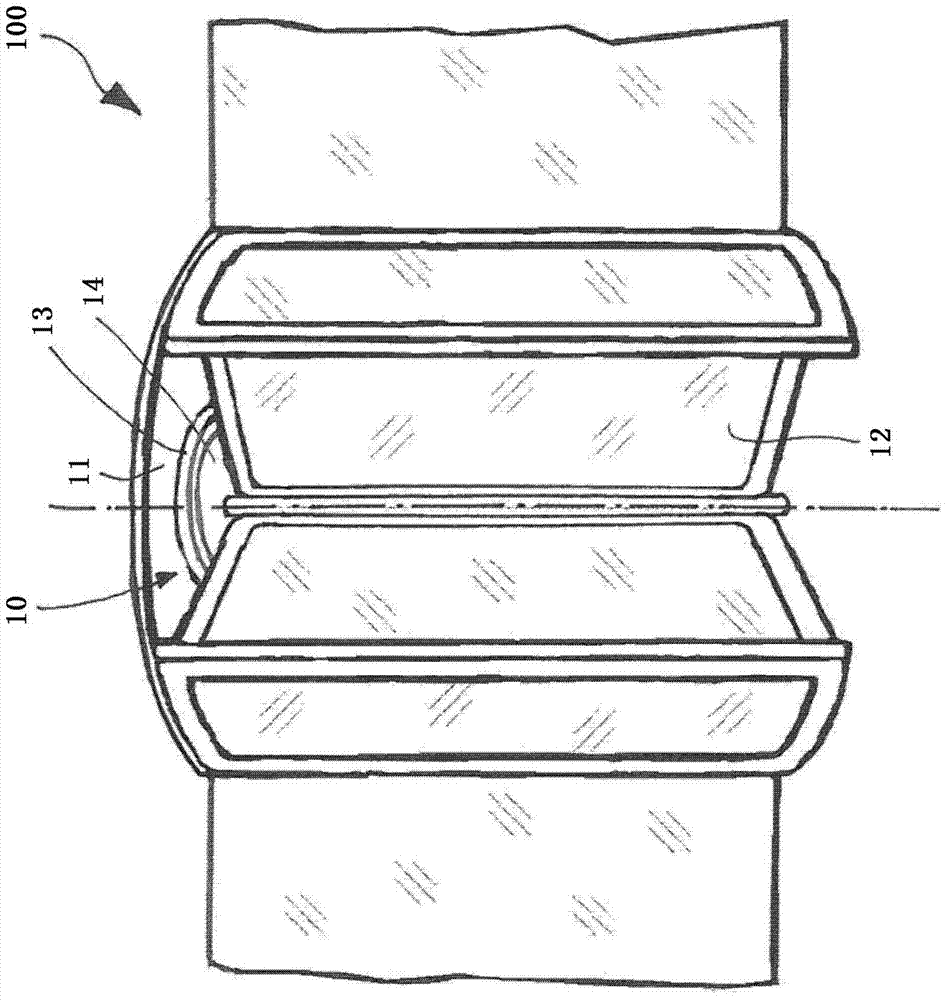

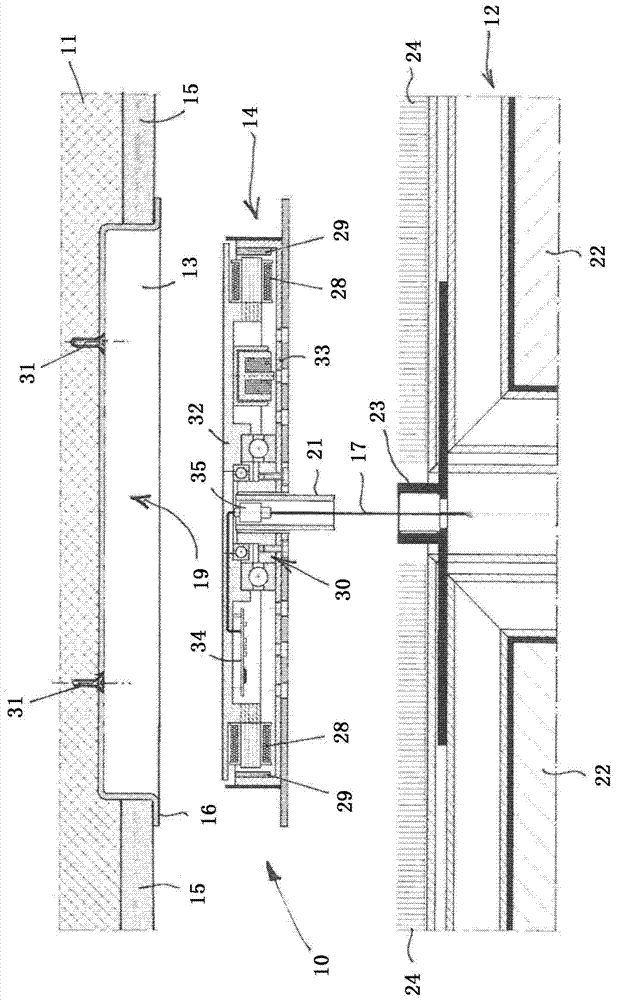

[0032] figure 1 An exemplary embodiment of a revolving door 100 is shown in a schematic perspective view, which is equipped in a retrofitted frame with a drive unit 10 which is arranged on the bottom side on a top element 11 of the revolving door 100 . The drive unit 10 is connected to the turnstile 12 of the revolving door 100 such that the drive unit 10 is located on the underside of the top element 11 and on the upper side of the turnstile 12 .

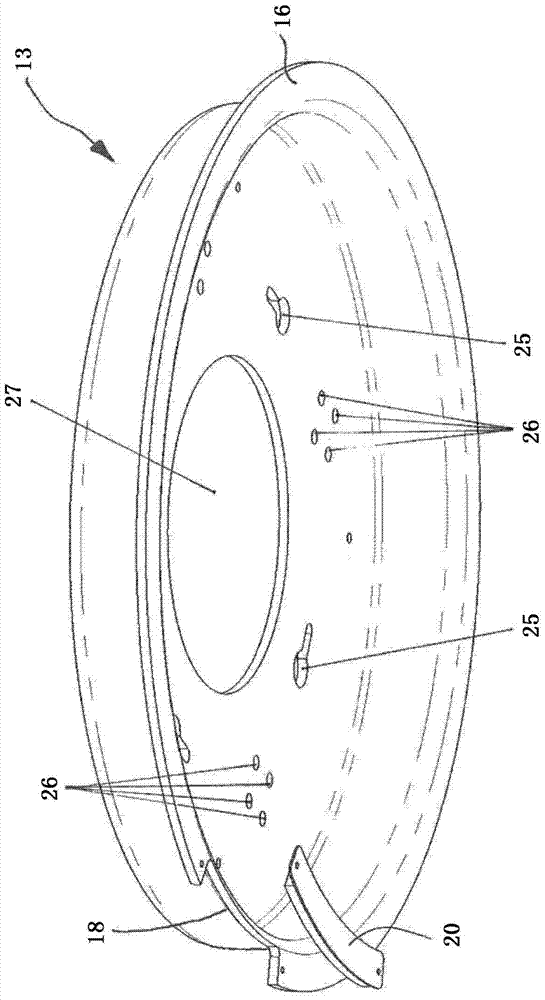

[0033] The drive unit 10 has a multi-pole motor 14 which has a flat cylindrical disk-shaped shape. The other components of the revolving door 100 and in particular the drive unit are not located on the upper side of the roof element 11 and the revolving door 100 can be integrated, for example, in a building facade which consists mainly of glass elements. In particular, the top element 11 of the revolving door 100 can be formed from a glass element, which can likewise be attached to the frame of the revolving door 100 in an additio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com