A simple detection device for the leakage between the pump barrel and the plunger and the tightness of the oil well pump

A detection device and sealing technology, which can be used in pump testing, measuring the acceleration and deceleration rate of fluid, and using liquid/vacuum for liquid tightness measurement. , oil well liquid production decline and other problems, to achieve the effect of simple device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

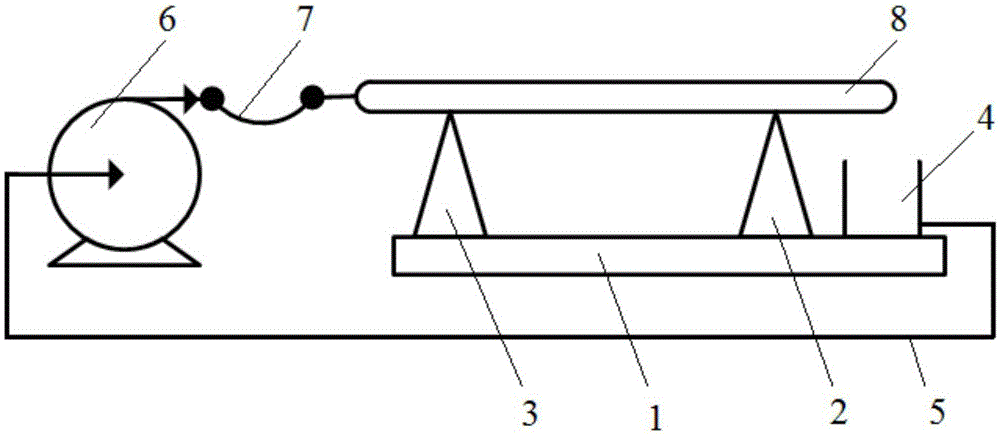

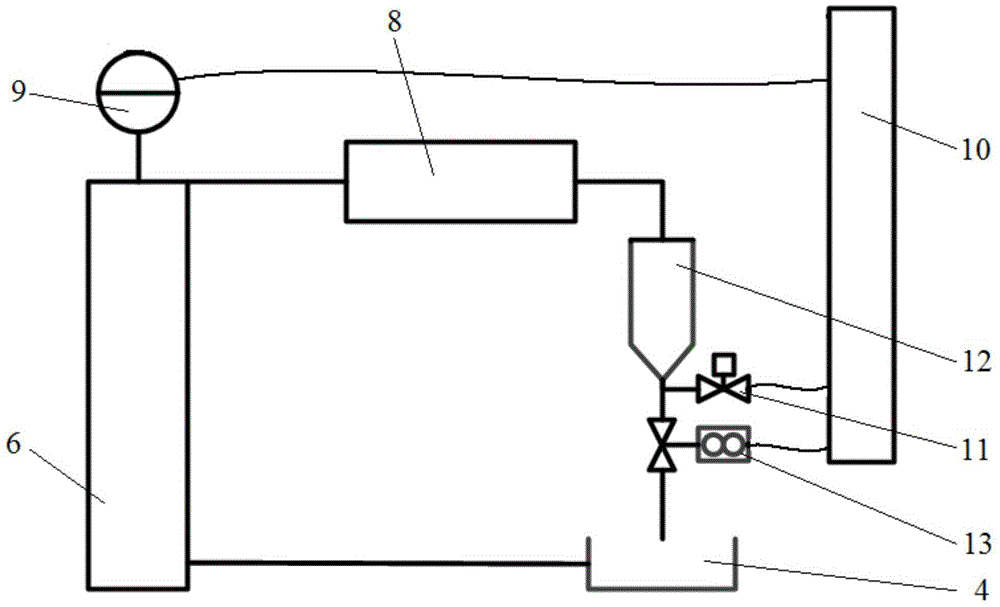

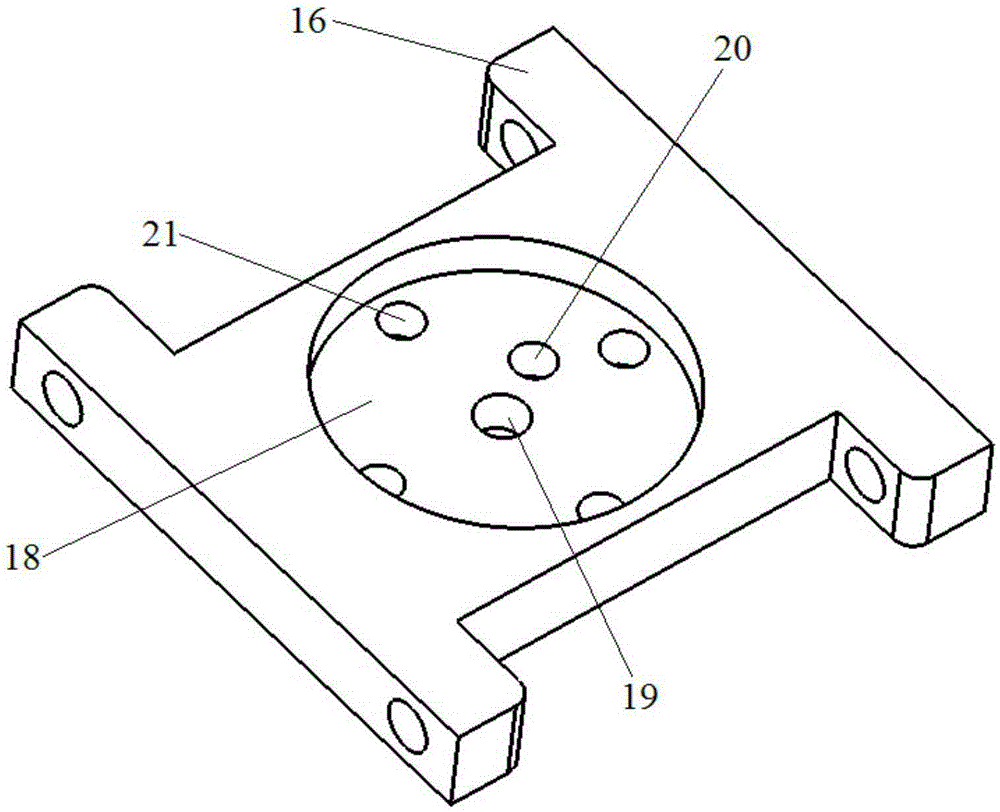

[0014] In the simple detection device for leakage between the barrel and the plunger of the oil well pump and the tightness of the present invention, a check valve and a pressure gauge 9 are sequentially installed on the oil outlet passage of the pressure test pump 6, and the oil outlet passage leads to the test bench. In the test bench, as image 3 , Figure 4 As shown, the four corners of the upper end cover 14 and the lower end cover 15 have fixed ears 16 respectively, and bolt through holes are arranged on the fixed ears 16, and four pillars 17 are connected with the upper end cover 14 and the four fixed ears of the lower end cover 15 respectively. 16 connections form the pump bucket fixed mount. The bottom of the upper end cover 14 has a circular sinkhole 18, such as image 3 As shown, there are three kinds of through holes in the circular sinkhole 18, the first one is an upper fixture fixing hole 19 with an internal thread at the center of the circular sinkhole 18, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com