Method for controlling DI material edge drop for six-roller mill

A technology of six-high rolling mill and control method, applied in rolling mill control device, metal rolling, metal rolling and other directions, can solve problems such as weak shape control, and achieve the effect of small scale of transformation, low cost and improved yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In combination with the specific embodiments of the present invention and the accompanying drawings, the application process of the technical solution will be further described.

[0042] The technical solution involved in this embodiment is carried out on the S4 frame of the 1420 unit. The S4 frame adopts a six-high rolling mill. Taking the production of DI materials with a width of 874mm-1062mm as an example, the width of the normally rolled strip steel is B=1062mm.

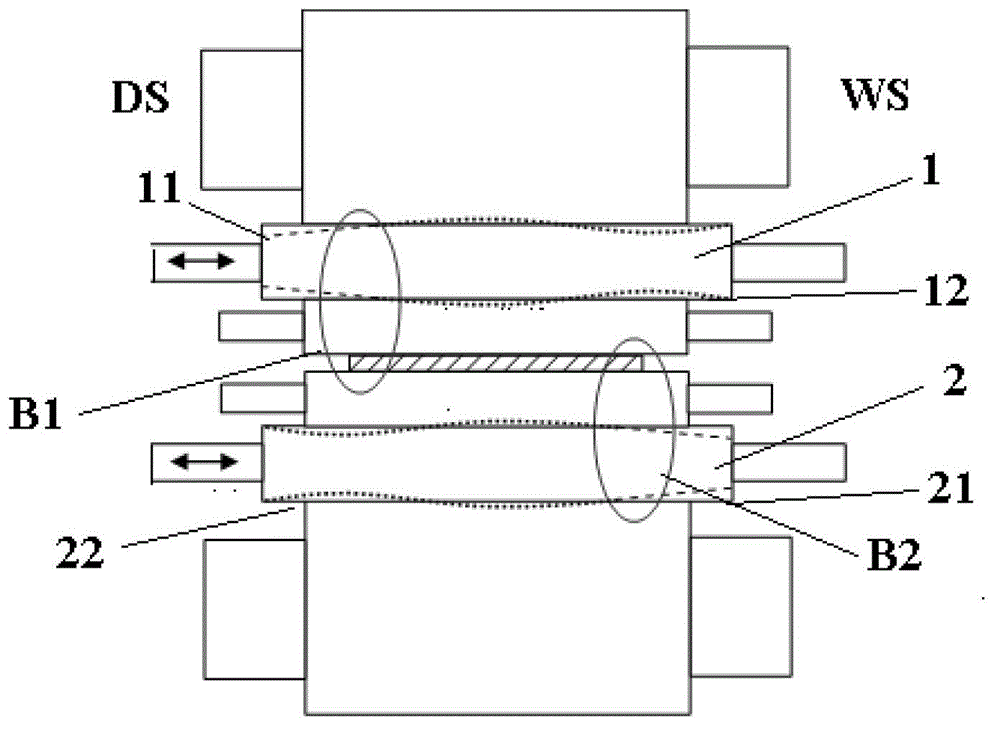

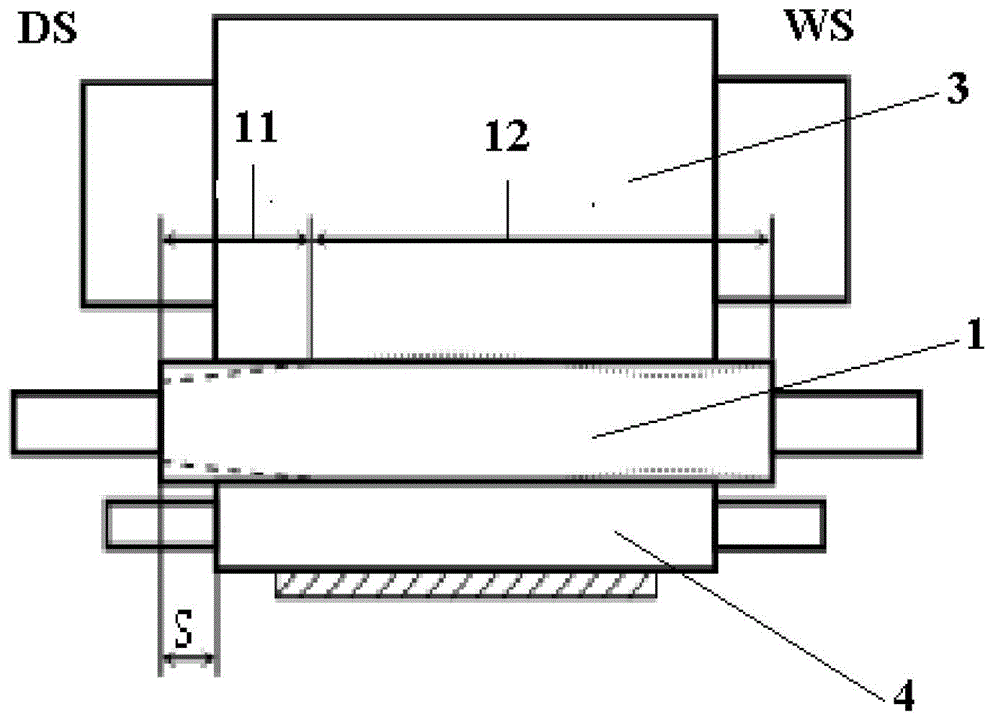

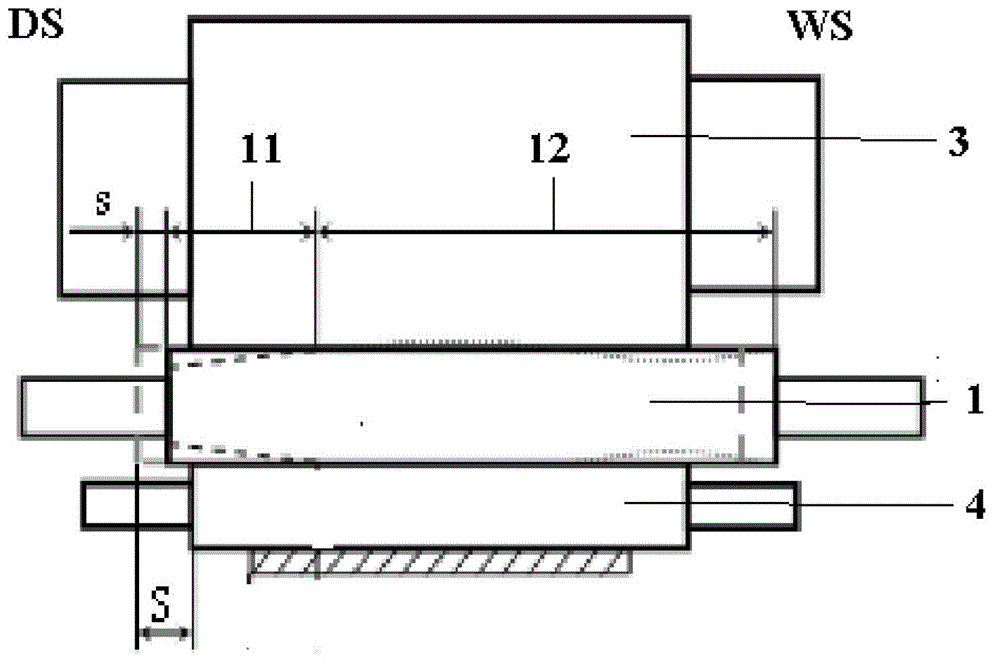

[0043] The six roll rolling mill in the present embodiment is as figure 1As shown, one side of the six-high rolling mill is called the driving side DS, and the side opposite to the driving side is the working side WS; there is a pair of intermediate rolls on the six-high rolling mill, which includes an upper middle roll above the strip Roller 1 and the lower intermediate roller 2 arranged under the strip, the upper intermediate roller 1 is provided with the first section 11 for edge drop control along its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com