Paper tube carrier vehicle

A technology of transport vehicles and paper tubes, which is applied in the direction of transportation and packaging, trolleys, motor vehicles, etc., can solve the problems of easy damage of paper tubes, poor practical performance, product variation and bending, etc., and achieve improved transportation effect, good stability, and reduced workload effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

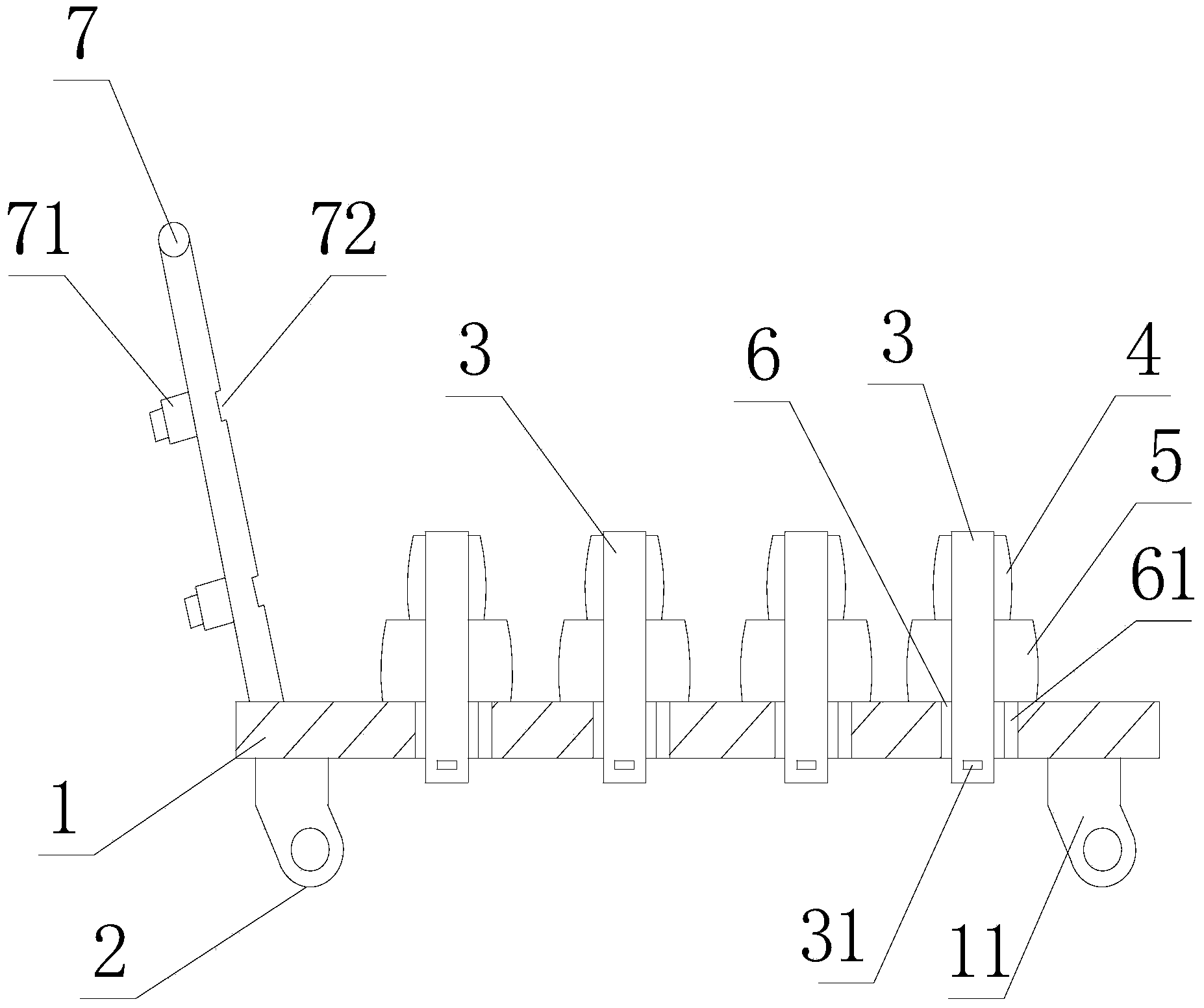

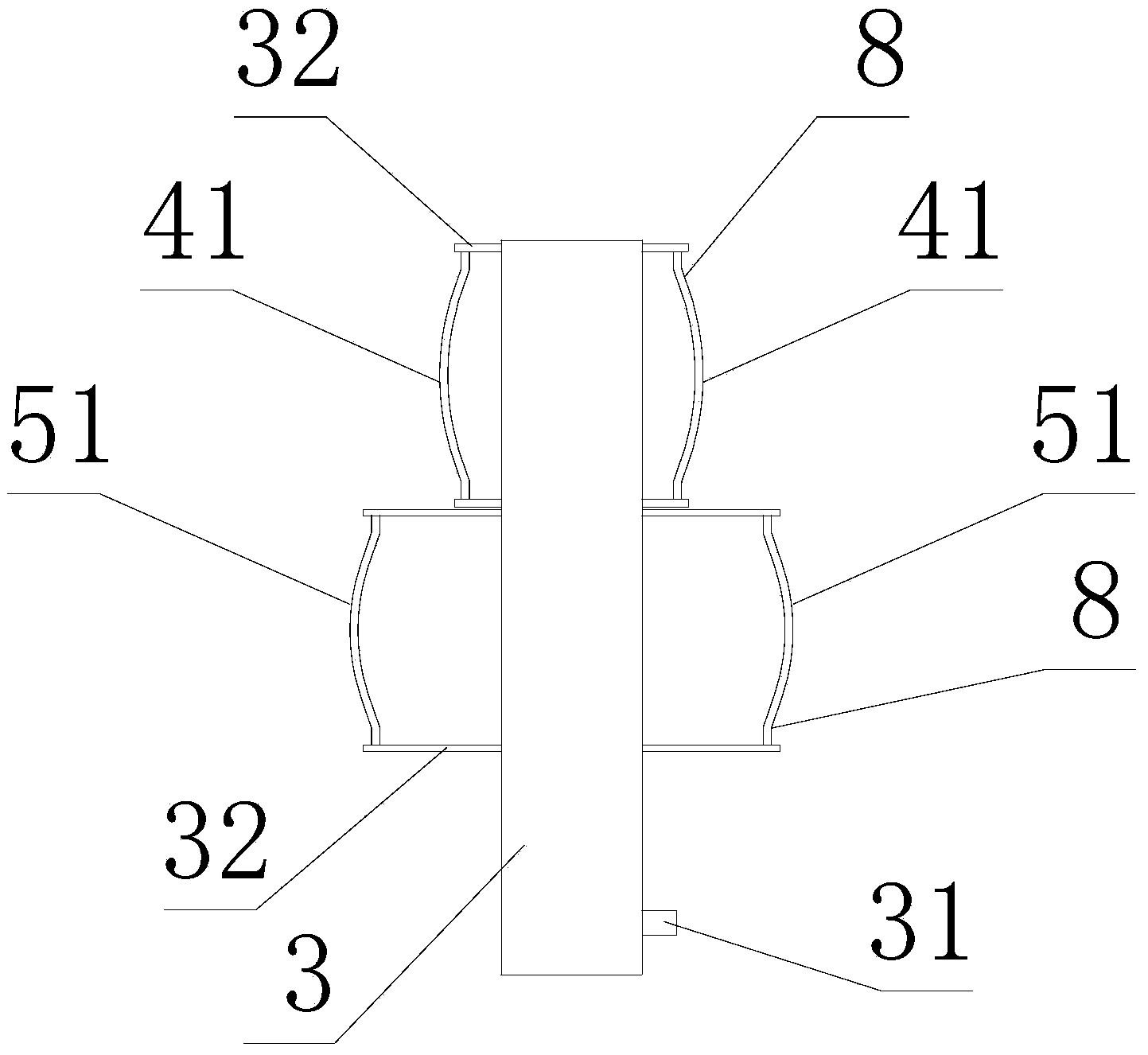

[0021] like figure 1 , figure 2 , image 3 As shown, a paper tube transport vehicle includes a base 1 with moving rollers 2 at the bottom, several detachable placement rods 3 arranged on the base 1, and a group of paper feeding tubes are arranged in the middle of the placement rods 3 The first connecting part 5 of the first connecting part 5 is provided with another set of second connecting part 4 for placing the paper feeding tube on the placing rod 3 above the first connecting part 5, and the placing rod 3 below the first connecting part 5 passes through On the base 1, the base 1 is provided with a mounting portion 6 matched with the placing rod 3, and the bottom end of the placing rod 3 is provided with at least one block 31 for locking the placing rod 3 on the base 1, The mounting part 6 is provided with a card slot 61 that matches the block 31, the distance between the block 31 and the first connecting part 5 is greater than the thickness of the mounting part 6, and th...

Embodiment 2

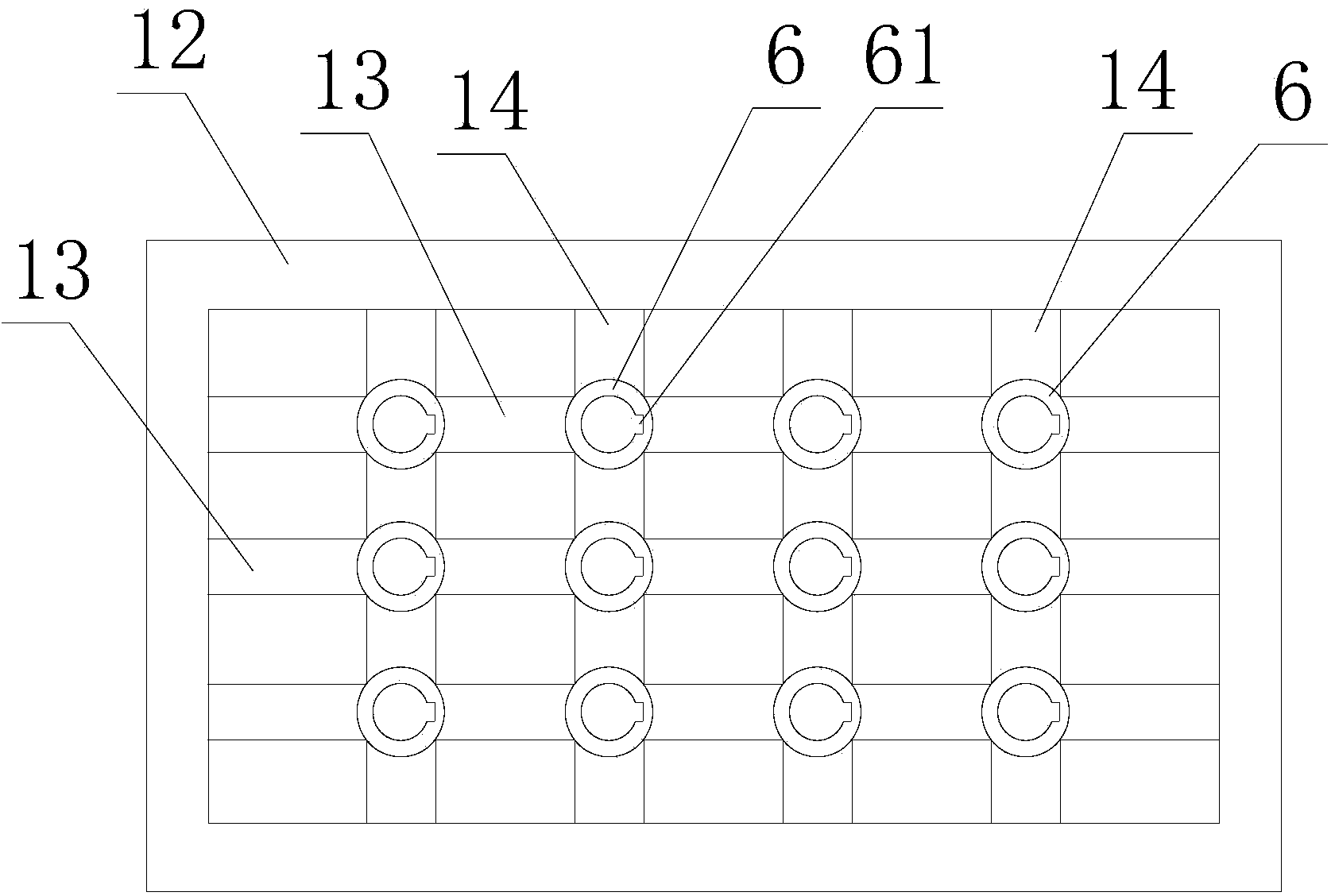

[0023] A paper tube transport vehicle as described in Embodiment 1, this embodiment has the following differences: Figure 4 As shown, the base 1 is grid-shaped, and the sleeves are arranged on the base 1 in a staggered manner, which has a simple structure, is easy to process, saves production costs, has good practical performance, and ensures that two adjacent paper tubes do not collide.

Embodiment 3

[0025] A kind of paper tube transport vehicle as described in embodiment one and two, this embodiment has the following differences: as Figure 5 As shown, the base 1 is a flat plate with a smooth surface, and the installation part 6 is a through hole arranged on the base 1, which is convenient for installation, simple in structure, and good in practical performance. Good performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com