A production process of high-grade pipeline steel with low compression ratio and thick specification

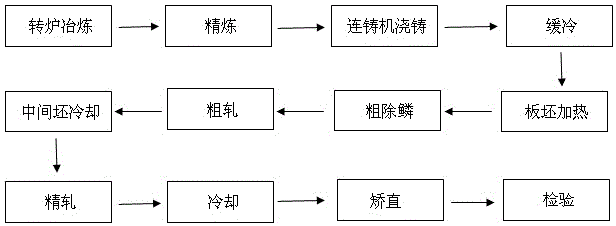

A technology with low compression ratio and production process, which is applied in the field of production process of low compression ratio thick gauge high-grade pipeline steel, which can solve unfavorable production of thick gauge X80 pipeline steel, unfavorable grain refinement control, high rough rolling start temperature, etc. problem, to achieve the effect of improving production guarantee ability, improving uniformity and performance stability, and low final cooling temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

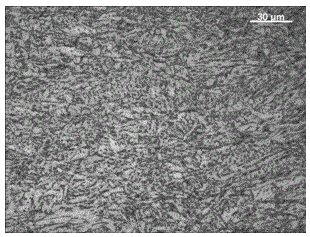

Embodiment 1

[0045]The present embodiment is the specific implementation production process of 33mmX80 with a compression ratio of 7.6. The selected process is suitable for the production of 33mmX80 pipeline steel by 4300 wide and thick plate rolling mill. The thickness of the billet is 250mm, the thickness of the finished plate is 33.2mm, the range of compression ratio is 7.4-7.6, and the total deformation is ≥85%. The process includes the following steps:

[0046] Smelting: adopt clean steel smelting methods, on the basis of ultra-low P and S, control the total amount of five major harmful elements, that is, control the sum of S, P, O, N, and H to less than 150ppm to ensure the purity of steel degree, uniformity. The main chemical composition of the steel is shown in Table 1: During the slab continuous casting process, the dynamic soft reduction technology is adopted, and the central segregation of the slab reaches Class C 1.0.

[0047] Table 133mmX80 chemical composition

[0048] ...

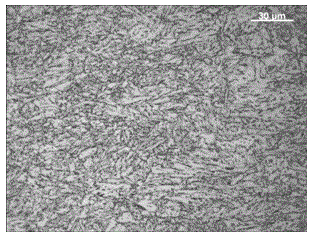

Embodiment 2

[0058] This embodiment is a specific implementation production process of 27mmX80 with a compression ratio of 9.3. The selected process is suitable for the production of X80 pipeline steel in the 4300 wide and heavy plate mill. The thickness of the billet is 250mm, the thickness of the finished plate is 27.2mm, the range of compression ratio is 9.1-9.3, and the total deformation is ≥85%. The process includes the following steps:

[0059] Smelting: adopt clean steel smelting methods, on the basis of ultra-low P and S, control the total amount of five major harmful elements, that is, control the sum of S, P, O, N, and H to less than 150ppm to ensure the purity of steel degree, uniformity. The main chemical composition of the steel is shown in Table 2: During the slab continuous casting process, the dynamic soft reduction technology is adopted, and the quality of the slab reaches C class 1.5.

[0060] Table 227mmX80 chemical composition

[0061]

[0062] Heating: In the he...

Embodiment 3

[0071] This embodiment is a specific implementation production process of 26.4mmX80 with a compression ratio of 9.5. The selected process is suitable for the production of X80 pipeline steel in the 4300 wide and heavy plate mill. The thickness of the billet is 250mm, the thickness of the finished plate is 26.6mm, the range of compression ratio is 9.3-9.5, and the total deformation is ≥85%. The process includes the following steps:

[0072] Smelting: adopt clean steel smelting methods, on the basis of ultra-low P and S, control the total amount of five major harmful elements, that is, control the sum of S, P, O, N, and H to less than 150ppm to ensure the purity of steel degree, uniformity. The main chemical composition of the steel is shown in Table 3: During the slab continuous casting process, the dynamic soft reduction technology is adopted, and the quality of the slab reaches C class 1.5.

[0073] Table 326.4mmX80 chemical composition

[0074]

[0075] Heating: In th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap