A rotary vertical drop test machine

A drop test, rotary technology, used in impact testing, machine/structural component testing, instrumentation, etc., to solve problems such as the inability to meet multiple drop tests for fragile samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

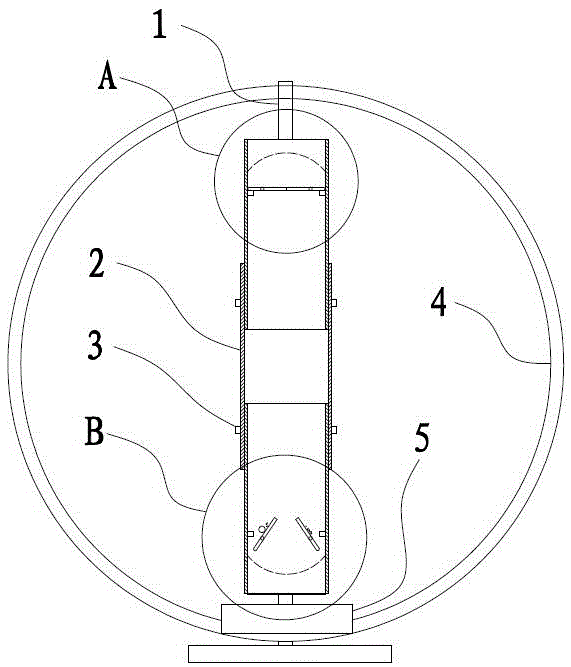

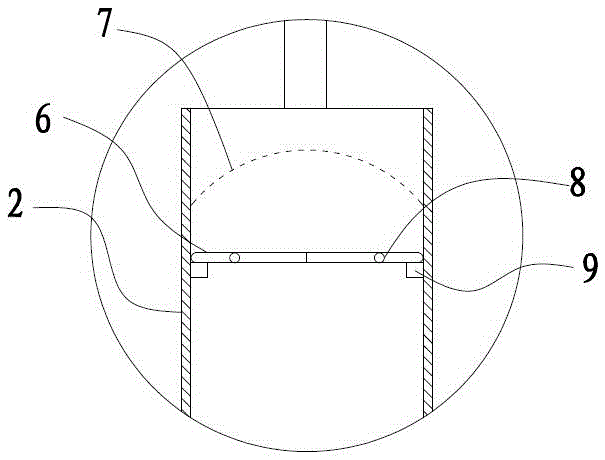

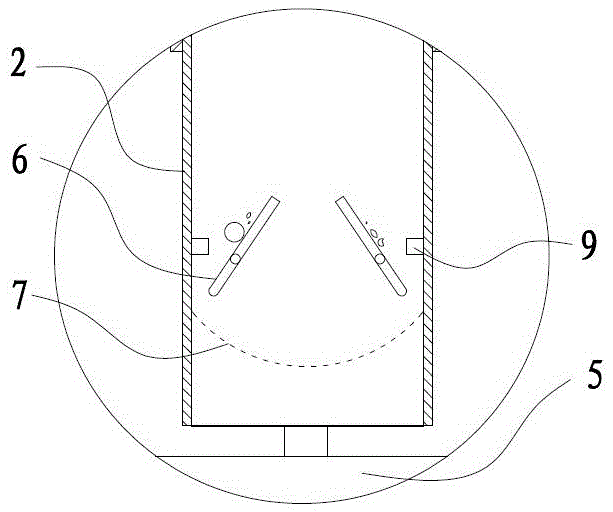

[0023] Embodiment: a kind of biomass pellet fuel rotary vertical drop test machine, such as figure 1 , Figure 4 shown. The device includes a support 1, and the support has a fixed base and a vertical pole. The middle part of the vertical rod of the bracket is connected with the falling cylinder 2 through the rotating shaft 10, and the rotating shaft clamps the falling cylinder through two hoops 3. The drop cylinder 2 is a cylinder with a square cross section, which is divided into three sections. The hoop 3 is clamped in the middle section of the drop cylinder 2, and the two ends of the drop cylinder 2 are slidably sleeved inside the middle section. The end sections can be synchronously telescopically adjusted. Both the rotation of the falling cylinder 2 and the expansion and contraction of the two ends of the falling cylinder 2 are driven by motors. A protective ring 4 is arranged around the rotation track of the falling cylinder 2 on the support 1, and a scrap box 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com