tofd test block automatic scanning device

A technology of scanning device and test block, which is applied in the field of ultrasonic testing, can solve problems such as easy bending and inaccuracy of maps, map errors, unfavorable data interpretation and measurement, etc., achieve stable data collection, convenient operation, and avoid incomplete scanning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

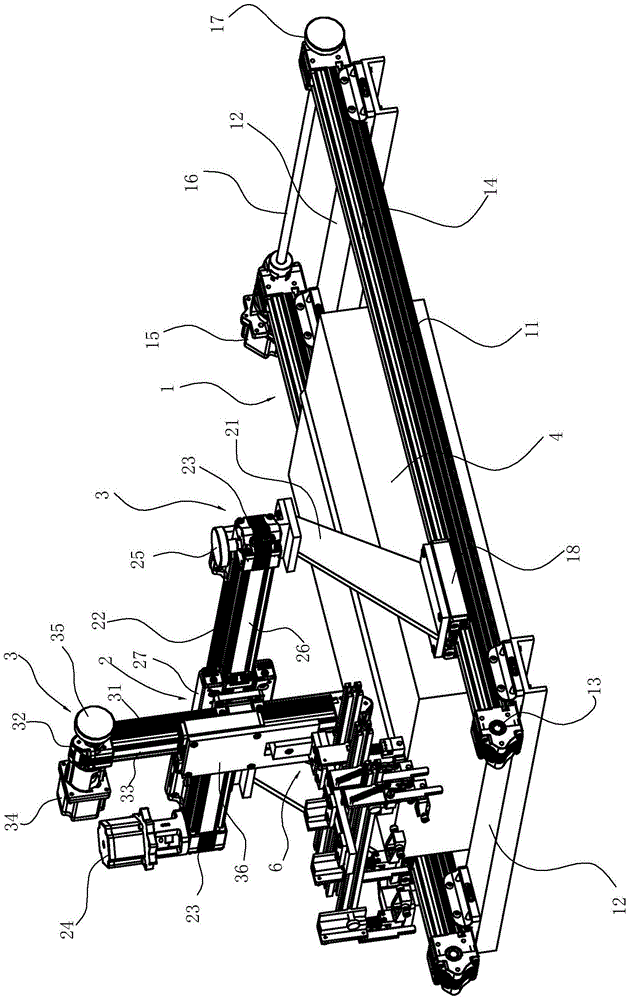

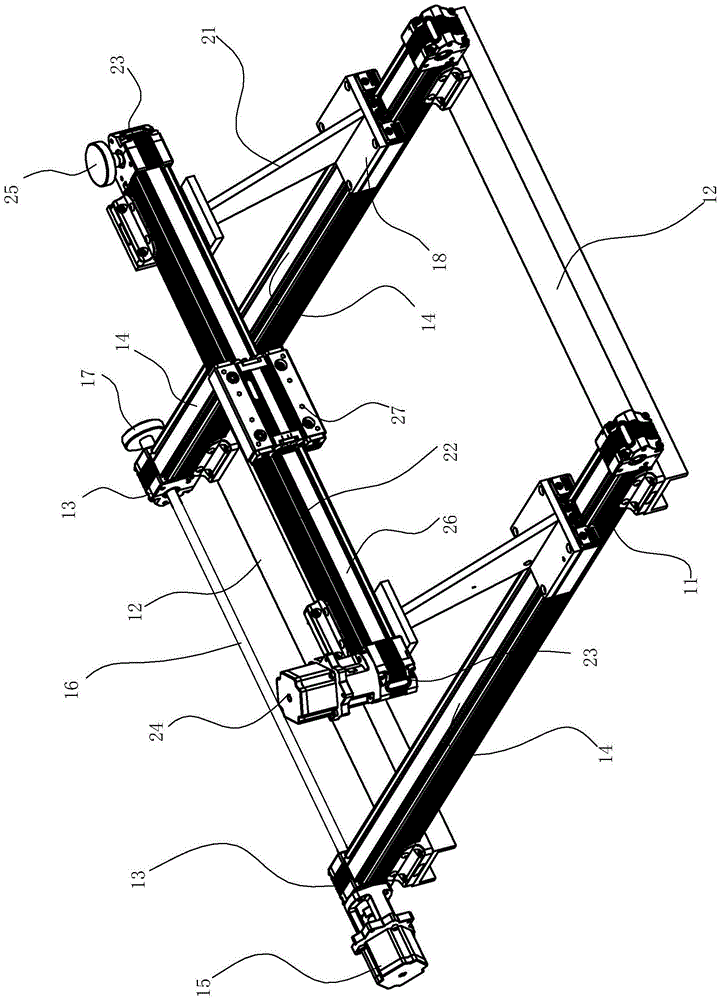

[0030] Such as Figure 1 to Figure 7 As shown, the TOFD test block automatic scanning device includes:

[0031] The scanning frame is sleeved on the outside of the test block 4, and includes a bottom frame formed by two parallel first rails 11 and connecting plates 12 connected to the two first rails. Two first rails 11 Arranged along the length direction (scanning direction) of the test block, the two first guide rails 11 are also components of the first module in the three-dimensional linear motion module in this embodiment.

[0032] The three-dimensional linear motion module is used to drive the connecting seat 6 to move in the X, Y, and Z three-dimensional directions. The three-dimensional linear motion modules in this embodiment are all linear motion modules with a synchronous belt structure.

[0033] The first linear motion module 1 is used to drive the connecting seat 6 to move along the X axis to scan the test block. It includes two first guide rails 11 shared with the sca...

Embodiment 2

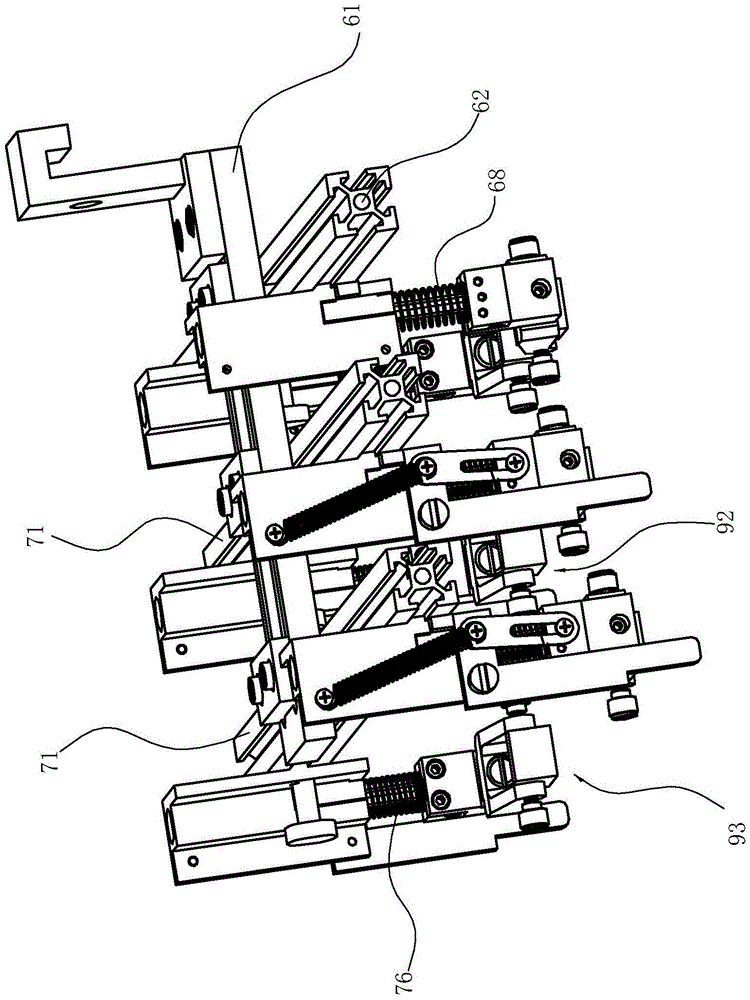

[0049] Such as Figure 8 As shown, the third linear motion module 3'in this embodiment adopts a ball screw structure. It includes a bracket 31' arranged on the second sliding block 27, and the bracket 31' is provided with a ball screw 32'. In this embodiment, there are two guide rails 33' on both sides of the screw, and a third sliding block 34' The third sliding block 34' is fixedly connected with the screw nut of the ball screw 32' and is slidably connected with the two guide rails 33'. The third transmission motor 35' is arranged on the bracket 31' and is coaxially connected with the lead screw 34'.

[0050] Compared with the third linear motion module of the synchronous belt structure in the embodiment 1, the third linear motion module of the ball screw structure in this embodiment has more accurate upper and lower positioning of the probe group, and has a power-off self-locking Features.

[0051] The rest of the content is the same as in Embodiment 1, and will not be repeate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com