Bottom-feeding vertical type axial flow threshing device

The technology of a threshing device and a vertical shaft is applied in the field of agricultural machinery, which can solve the problems of poor cleaning and separation operation effect, affecting the operation efficiency of machines and tools, and low grain cleanliness, etc., and achieves novel structure, good feeding smoothness and operation efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

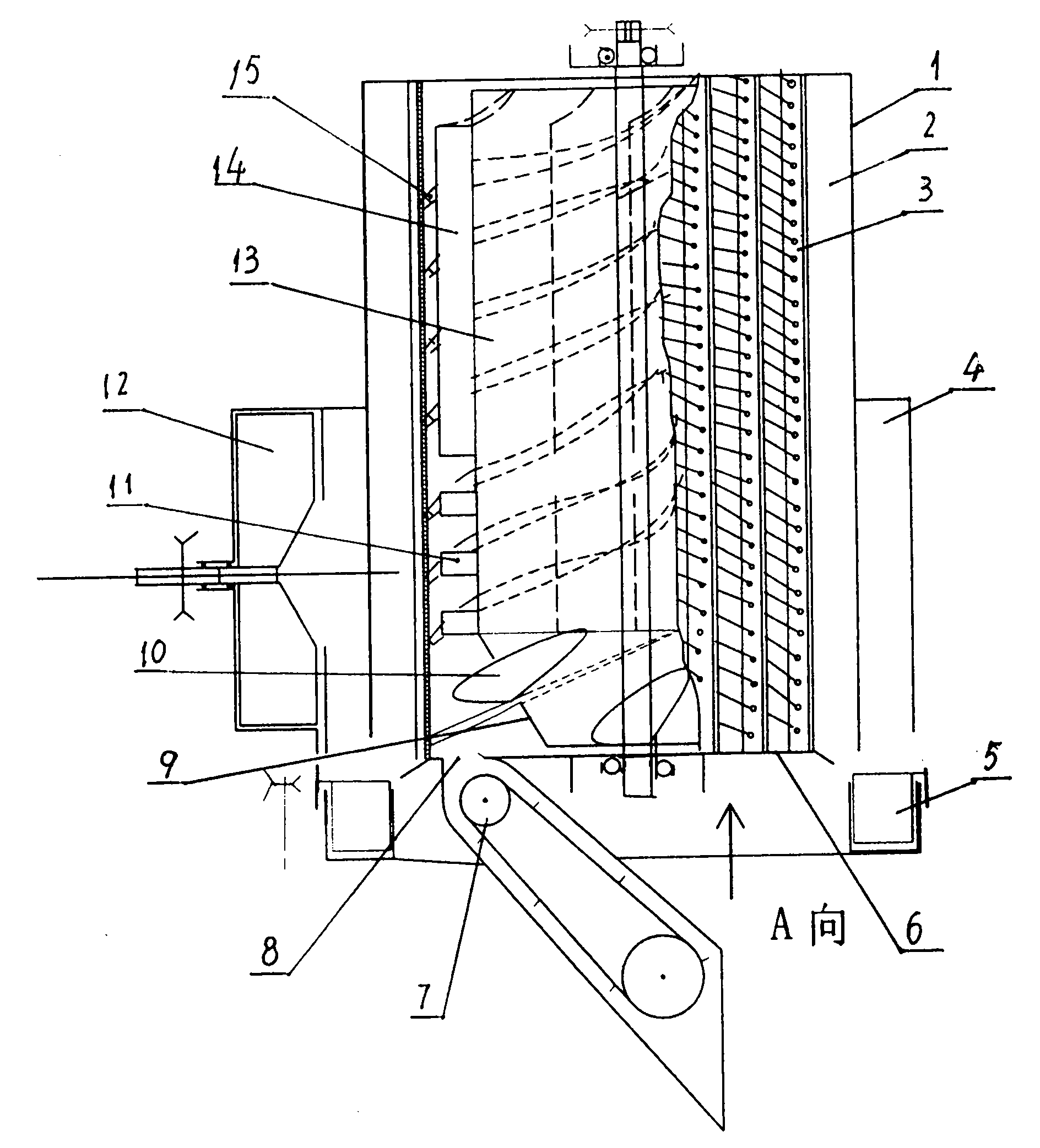

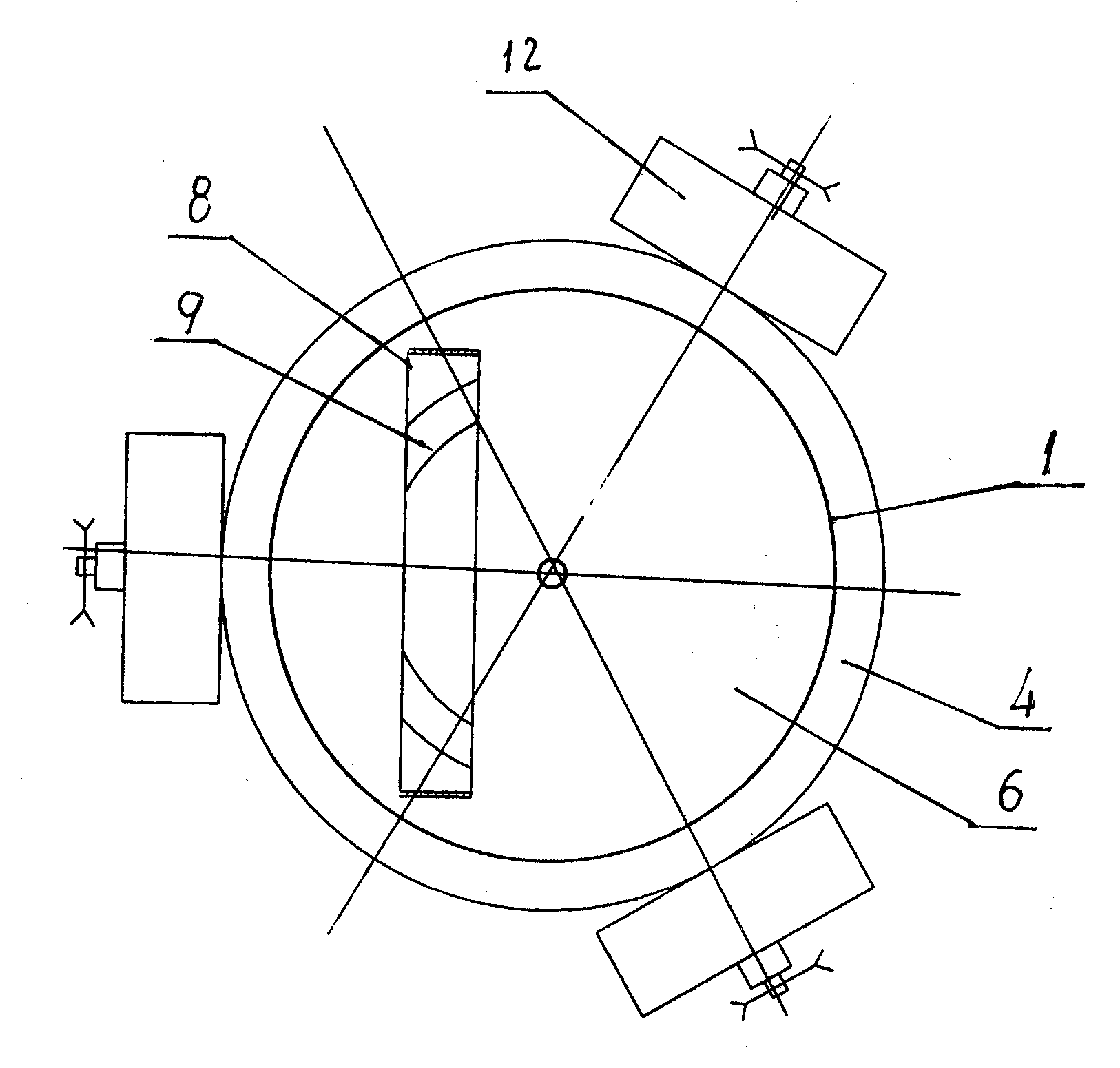

[0010] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A bottom-fed vertical axial flow threshing device, in which a threshing cylinder 13 is vertically and rotatably installed in a casing 1, and a fixed cylindrical concave plate 3 is integrally contained in the casing 1 outside the threshing cylinder 13. An annular separation chamber 2 is formed between the cylindrical concave plate 3 and the housing 1, and an annular grain collection tank 5 matching it is arranged under the bottom of the annular separation chamber 2, and is fixed on the outside of the lower side of the threshing drum 3. The threshing tooth 11 is fixed with a spiral deflector 15 on the inner side of the cylindrical concave plate 3, and a feeding port 8 is provided on the side of the bottom plate 6 of the cylindrical concave plate 3. Below the feeding port 8 Equipped with a feeding device 7, an inverted cone 9 is fixed on the lower end surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com