A controllable discharge device for a pulverizer

A technology of a pulverizer and a feeding barrel, which is applied in the direction of grain processing, can solve the problems of high energy consumption, low output, uneven product thickness, etc., and achieves the effect of simple and practical installation and guaranteed production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

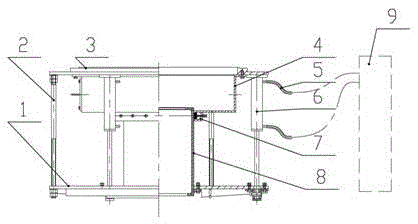

[0015] see figure 1 , which is a structural schematic diagram of a preferred embodiment of a controllable discharge device of a pulverizer in the present invention. As shown in the figure: it includes a transfer bin 4 arranged below the discharge port 3, the bottom surface of the transfer bin 4 is pierced with a discharge cylinder 8 that can move up and down, and the lower end of the discharge cylinder 8 is connected to the adjustment tray 1, the adjustment tray 1 is horizontally positioned on the double thread head guide rod group 2, and the adjustment tray 1 is connected to the driving mechanism for moving up and down.

[0016] During use, when the ground material flows out from the discharge port 3, it is concentrated inside the transfer bin 4, and when the material accumulation height in the transfer bin 4 is higher than the height of the upper opening of the discharge cylinder 8 in the transfer bin 4, from The discharge barrel 8 overflows. At this time, the outer wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com