Coiled tubing flush ignition device

A technology of ignition device and tubing, which is applied in wellbore/well components, production fluid, earthwork drilling and production, etc. It can solve problems such as economic loss, delay of operation period, and inability to determine whether the tubing is clean, so as to reduce pollution and improve success rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

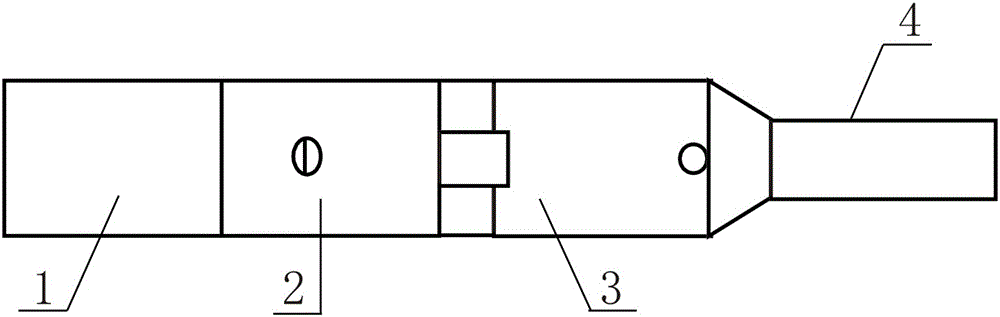

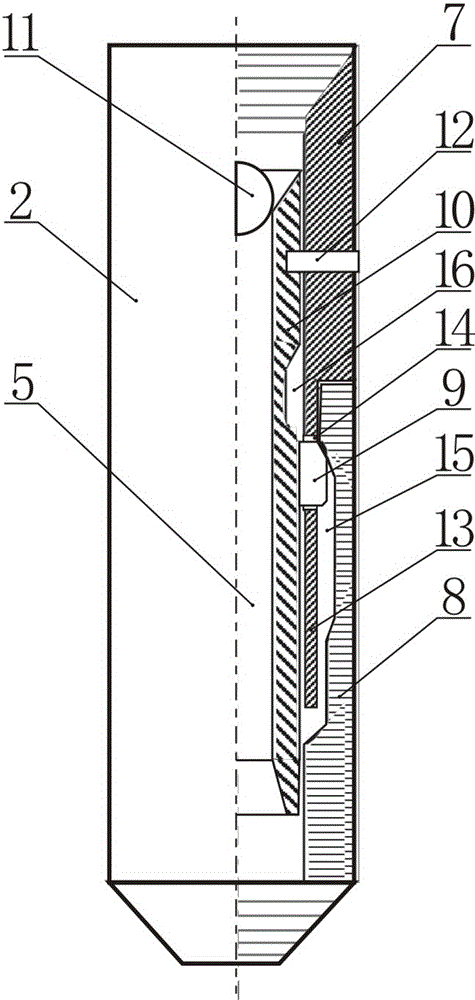

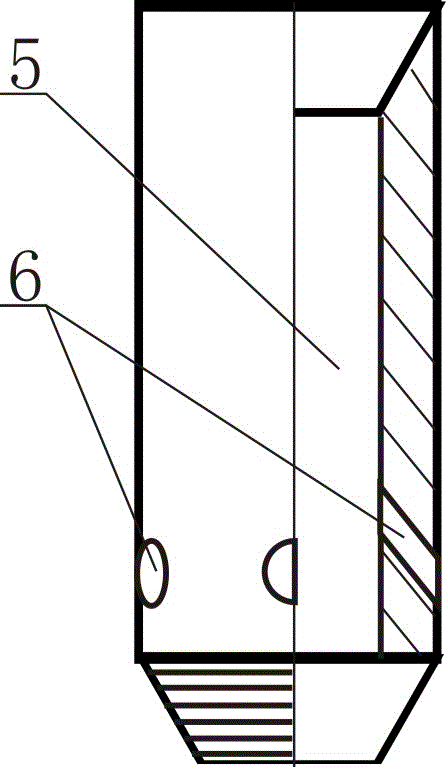

[0018] Such as figure 1 , 2 As shown, the coiled tubing flushing and ignition device is composed of a tubing joint 1, a ball-pitching shear separation component 2, a flushing pipe 3 and an ignition rod 4. , one end of the flushing pipe 3 is threadedly connected to the tubular lower joint of the ball-pitching-shearing separation assembly 2, and the other end is threadedly connected to the ignition rod 4, and the oil pipe joint, the ball-pitching-shearing separation assembly, and the flushing pipe are respectively provided with interconnected flushing liquids channel 5, the wall of the flushing pipe 3 is provided with a flushing hole 6 communicating with the flushing liquid passage 5; A ball seat 10, a steel ball 11 and a pin 12 are formed. The tubular insertion part 13 at the lower end of the tubular upper joint 7 is inserted into the upper port of the tubular lower joint 8. The left pipe wall and the right side of the tubular insertion part 13 are The side tube walls are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com