Fire adjustment device

An adjustment device and firepower technology, applied in the field of firepower adjustment devices, can solve the problems of large-scale motors, increased power consumption, and increased motor costs, and achieve the effects of miniaturization, prevention of ignition failure, and reduction of power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

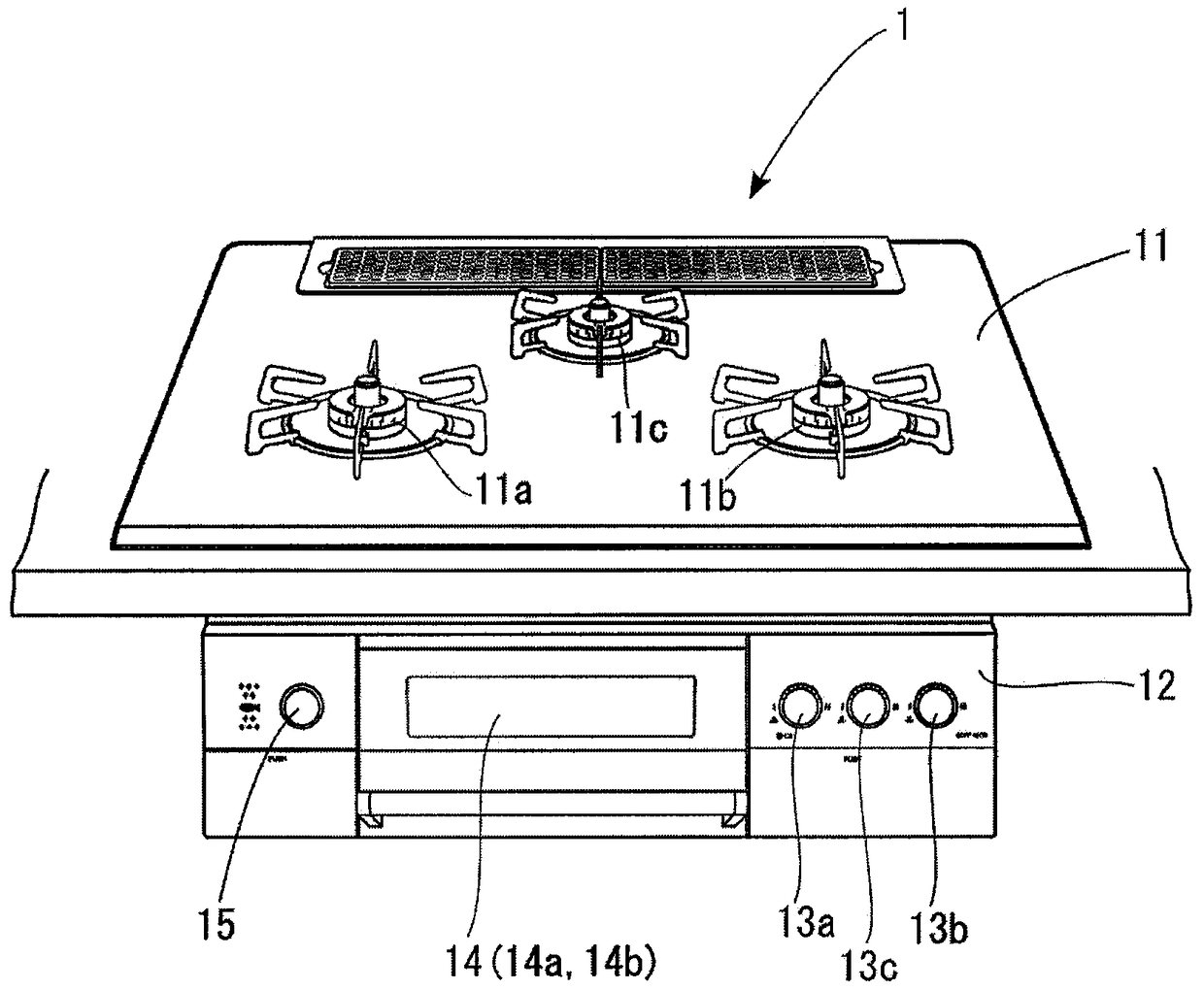

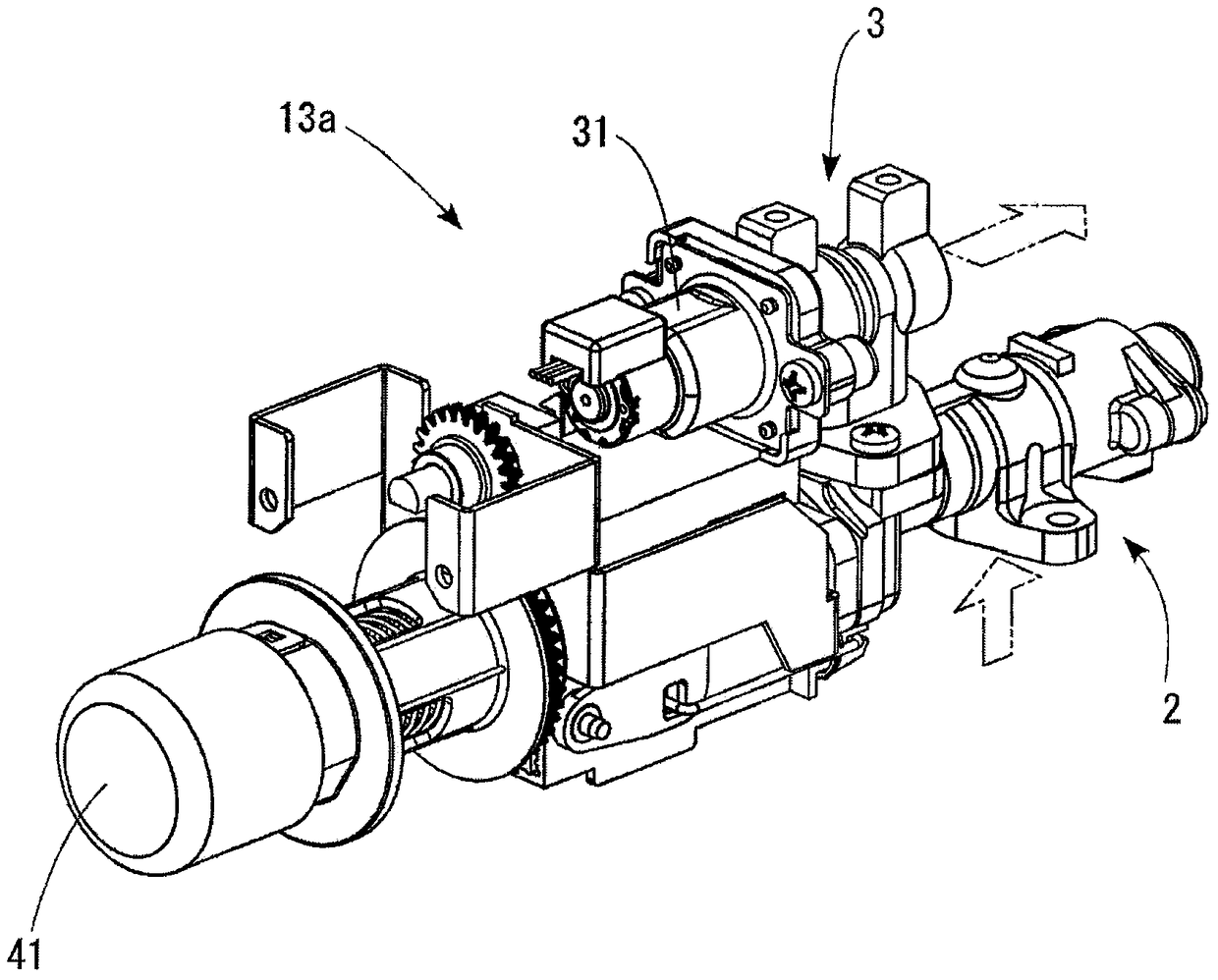

[0052] refer to figure 1 , No. 1 is a gas stove suitable for the fire power regulating device of the present invention. A top plate 11 is arranged on the upper surface of the gas stove 1, and three gas burners 11a, 11b, 11c are arranged on the top plate 11. On the front panel 12 of the gas stove 1, there are fire power adjustment devices 13a, 13b, 13c for igniting, extinguishing and fire power adjustment of each gas burner 11a, 11b, 11c. In addition, a grill cabinet 14 is provided approximately at the center of the front panel 12 , and an upper burner 14 a and a lower burner 14 b are provided in the grill cabinet 14 . In addition, the ignition, extinguishment, and adjustment of the heating power of the upper burner 14 a and the lower burner 14 b are performed by the heating power adjusting device 15 .

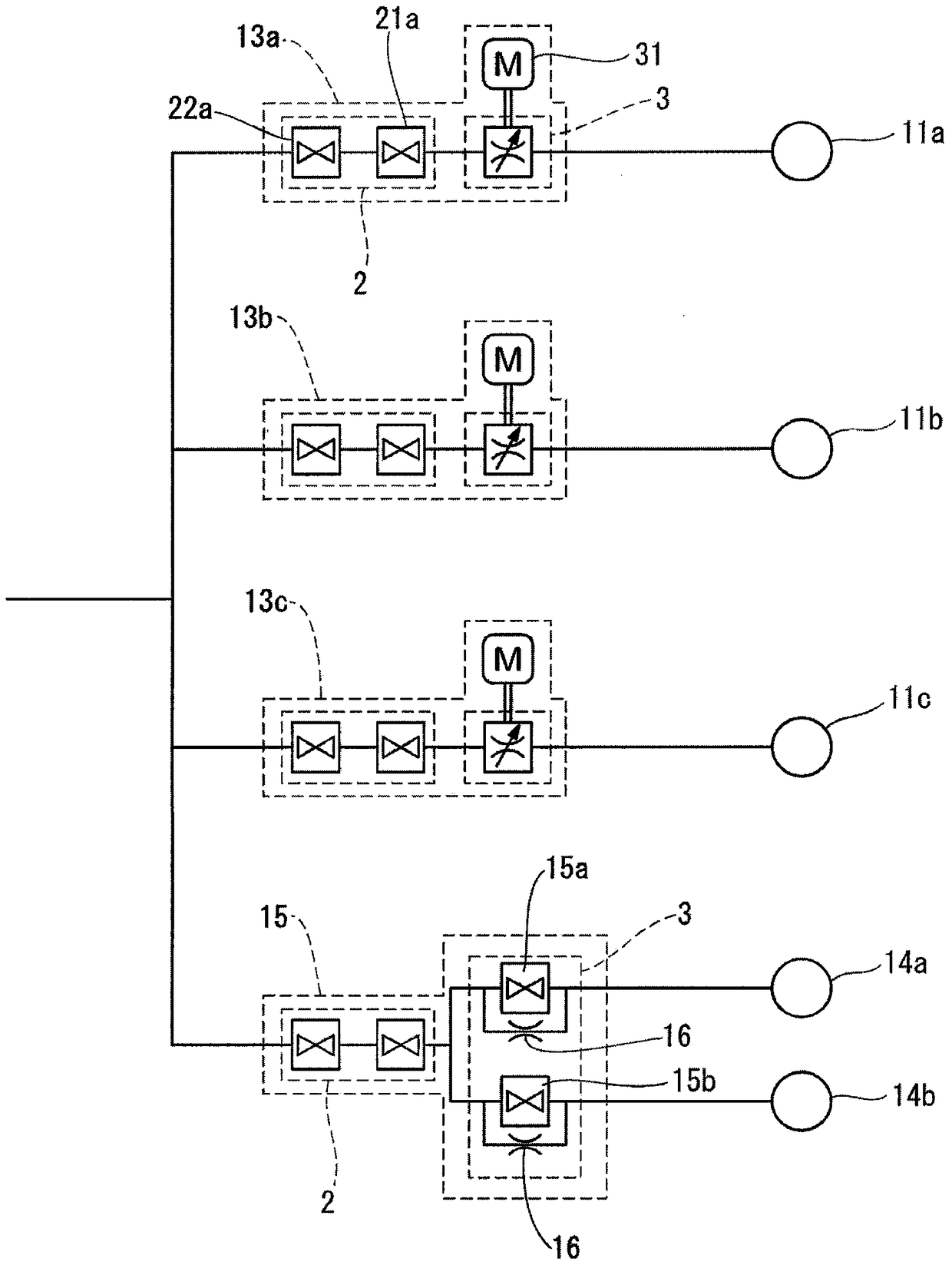

[0053] refer to figure 2 , in the present embodiment, the gas supply pipeline is separated into four that are arranged in parallel, and the fire power adjustment devices 13a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com