A Gas Generator with Wide Range Adjustable Flow and Temperature

A gas generator, a large-scale technology, applied in the combustion chamber, combustion method, combustion equipment and other directions, can solve the problems of poor ignition reliability and combustion stability of the gas generator, and achieve good operation effect, simple structure, and large-scale The effect of adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

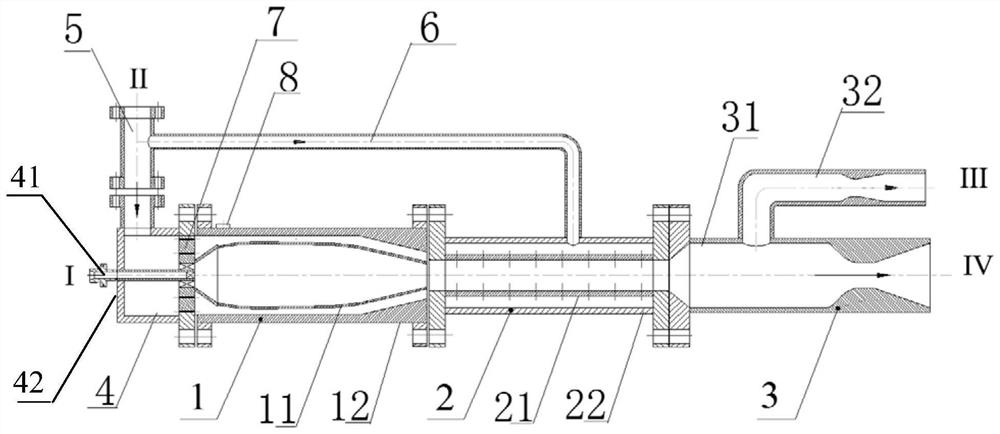

[0026] Such as figure 1 In this embodiment, the gas generator whose flow and temperature can be adjusted in a wide range is composed of four parts: the head 4, the combustion section 1, the mixing section 2 and the flow diversion section 3. Each section is connected by flanges, copper gaskets or graphite wound gaskets seal.

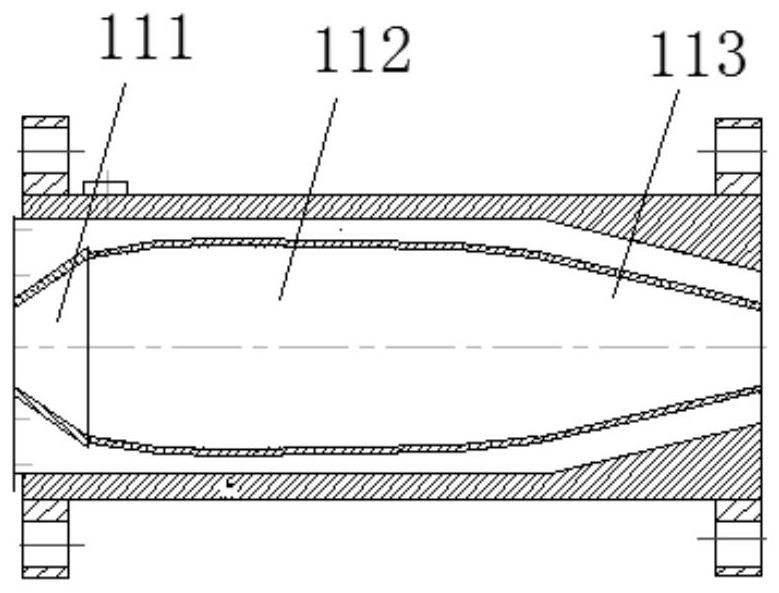

[0027] Wherein the head 4 comprises a head inner tube 41 and a head outer tube 42 coaxially set, the head outer tube 42 is equipped with an air pipeline 5, an air passage is formed between the head inner tube 41 and the head outer tube 42, The head inner tube 41 is a fuel channel; the combustion section 1 includes a coaxially set combustion section inner tube 11 and a combustion section outer tube 12. There is an air through hole, and the air in the air channel is sprayed into the inner tube 11 of the combustion section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com