Experimental device and experimental method for simulating dynamic leakage and leaking stoppage of drilling fluid

An experimental device and drilling fluid technology, applied in earthwork drilling, wellbore/well components, measurement, etc., can solve problems such as inability to use simulation, inability to simulate leakage phenomena well, ignoring drilling fluid flow, etc., and achieve experimental error Small size, easy operation, large core size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

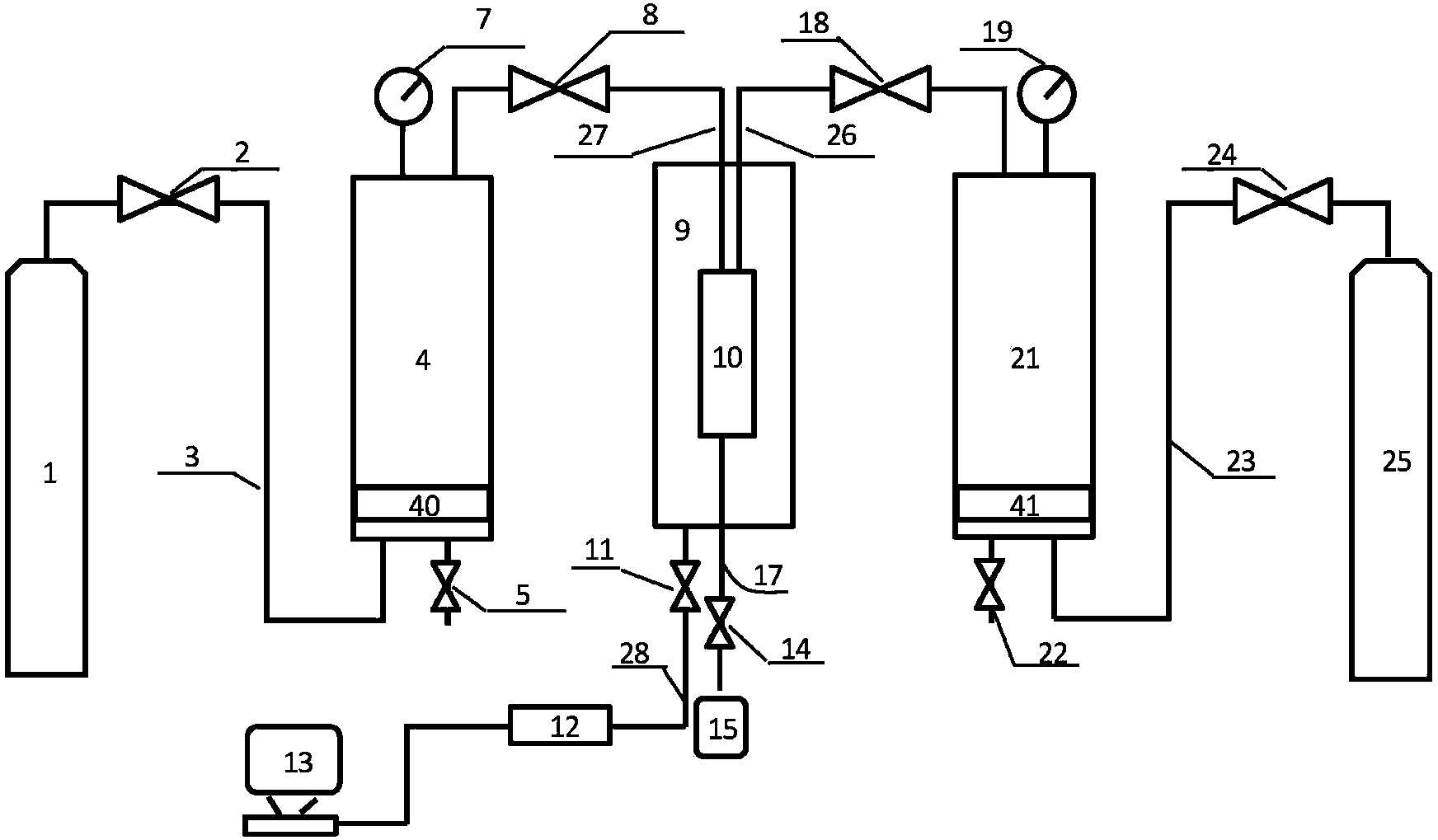

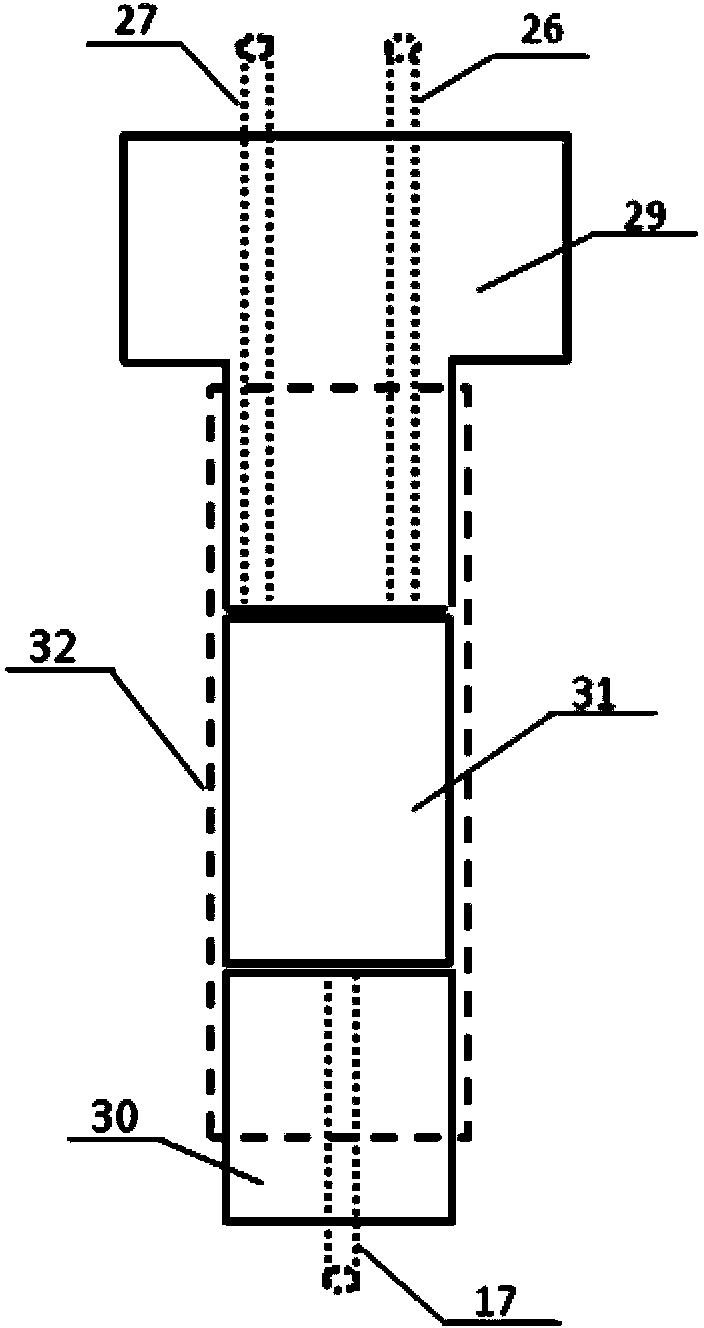

[0033] Such as figure 1 As shown, the experimental device for simulating the dynamic loss and plugging of drilling fluid includes: a first high-pressure nitrogen cylinder 1, a first circulation cylinder 4, a loss test cylinder 9, a core holder 10, a second circulation cylinder 21, and a second high-pressure nitrogen cylinder. A nitrogen cylinder 25, a servo-controlled injection pump 12; a core holder 10 is placed in the leakage test cylinder 9.

[0034] The first high-pressure nitrogen cylinder 1 is connected to the bottom end of the first circulation cylinder 4 through the first high-pressure pipeline 3, and the first pressure-reducing valve 2 is set on the first high-pressure pipeline 3; high-pressure nitrogen is housed in the first high-pressure nitrogen cylinder 1, with To provide pressure to the drilling fluid in the first circulation cylinder 4; the first piston 40 is provided in the first circulation cylinder 4, and the first piston 40 is used to realize the isolation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com