Method and device for implementing the same

A technology of impact head and back groove, which is applied in the direction of driving devices, earthwork drilling, cutting machinery, etc., and can solve problems such as damage to the impact power box, large contact area with materials, and equipment that cannot work continuously

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

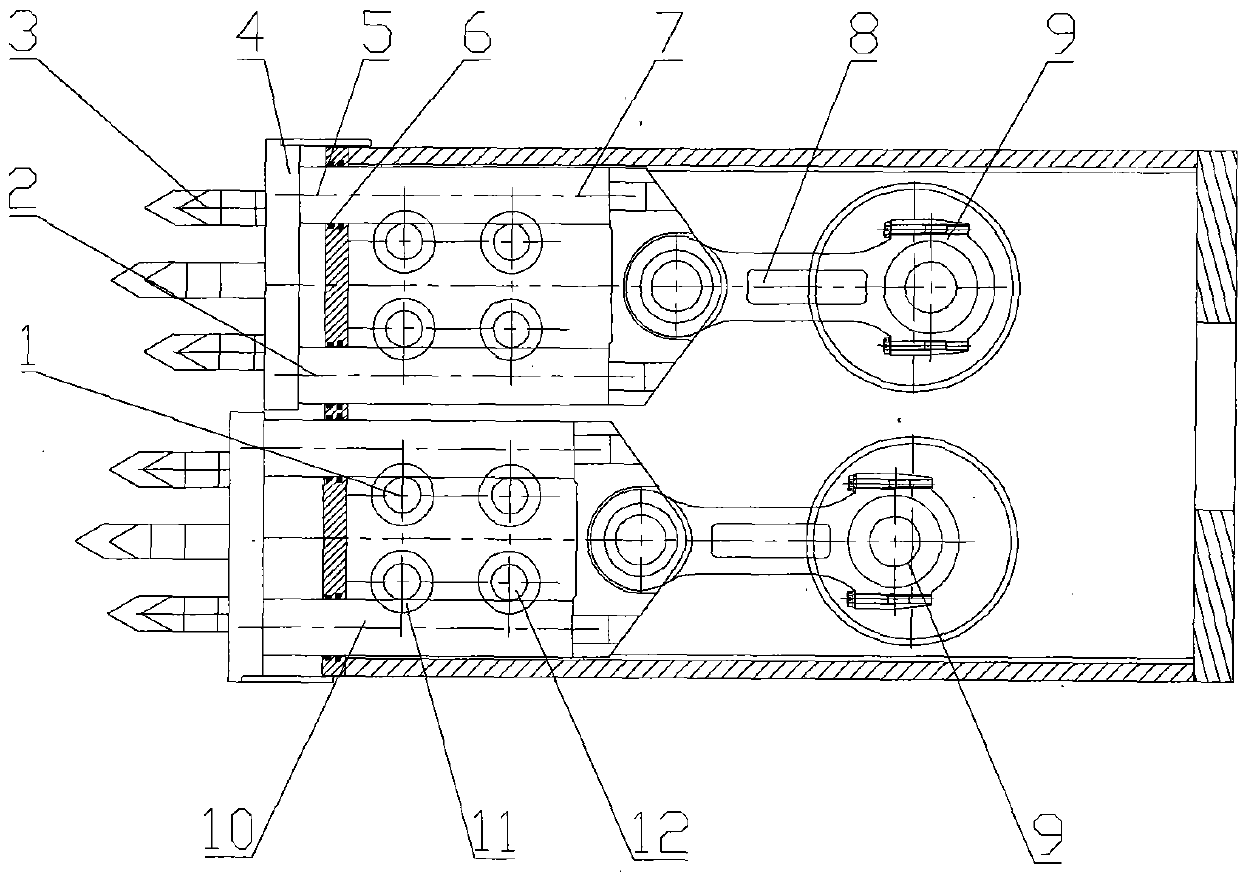

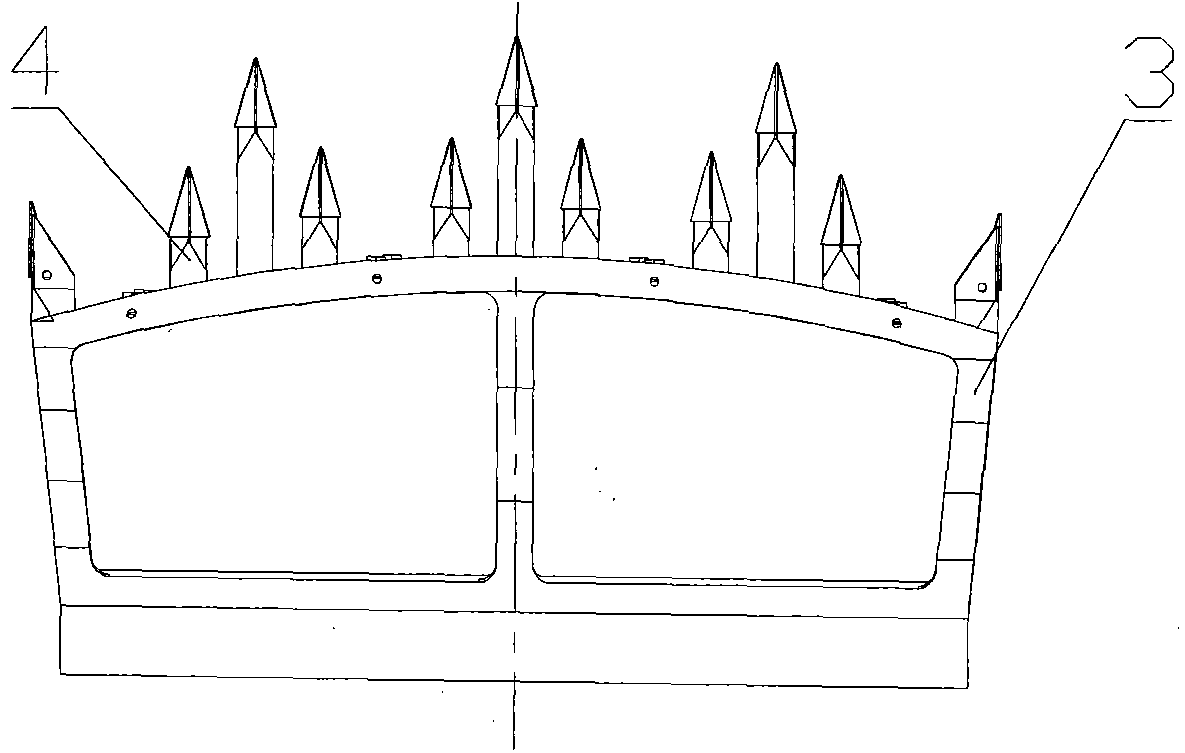

[0088] figure 1 To Fig. 4 is the method for increasing and / or widening the righting impact head with the back groove and the method for implementing the method in embodiment 1. The use of the back groove to increase and / or widen the righting impact head device, the use of the back groove to increase And / or the widening and righting impact head device comprises opposite back groove guide mechanism 37, impact supporting mechanism 12, driving mechanism 9, impact head 3 etc., and impact head 3 comprises gear seat 4 etc., and opposite back groove guide mechanism 37 comprises rolling friction pair The back groove structure 10, the impact guide 7, etc., the rolling friction pair back groove structure 10 includes an upper rolling friction groove 1, a lower rolling friction groove 11, etc., and the upper rolling friction groove 1 and the lower rolling friction groove 11 include guide rolling friction body 6, etc., the impact guide 7 includes an upper impact guide 5, a lower impact guid...

Embodiment 2

[0106] Figure 5 It is the heightening and / or widening centering impact head device described in Embodiment 2. The difference from Embodiment 1 is that the upper arc-shaped rolling friction groove 13 and the lower arc-shaped rolling friction groove 14 are arranged on the gear seat 4 In the U-shaped guide frame 15 formed with the upper impact guide 5 and the lower impact guide 2 or in the frame-shaped guide frame 38 or cylindrical guide frame, the tooth seat 4 will correspond to the upper impact guide 5 and the lower impact guide 2. Fastened on the upper arc-shaped rolling friction groove 13, the lower arc-shaped rolling friction groove 14, etc., the power impact member 8 drives the tooth seat 4 or the upper impact guide 5, the lower impact guide 2, etc. to reciprocate, and the upper impact guide 5 , the lower impact guide 2, etc. realize rolling friction reciprocating motion under the support of the upper arc-shaped rolling friction groove 13 and the lower arc-shaped rolling f...

Embodiment 3

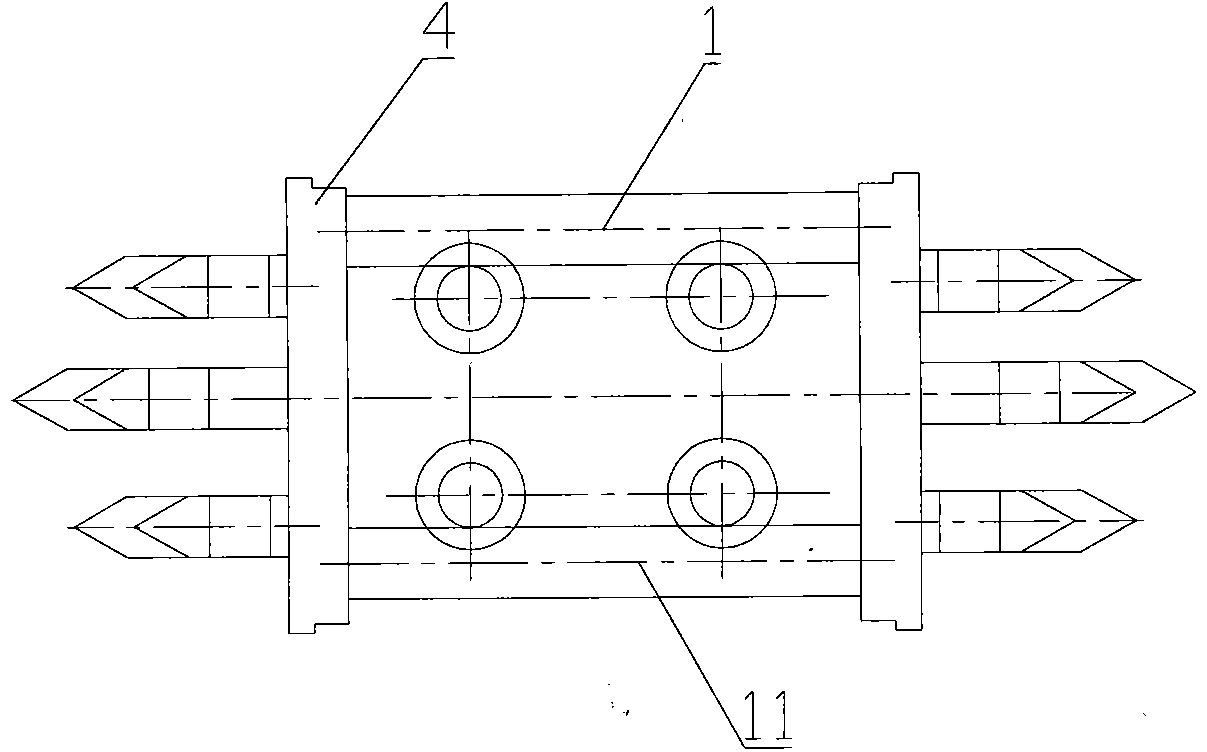

[0109] Figure 6 to Figure 7 For embodiment 3, the use of back groove heightening and / or widening of the righting impact head device is different from embodiment 1 in that the rolling elements 16 on the upper part of the upper impact guide 5 and the lower impact guide 2 are reduced. The rolling elements 16 etc. reduce the height of the back groove guide mechanism 37, thereby reducing the height of the gear seat 4, etc., use the back groove guide mechanism 37 to reduce the use quantity of the rolling elements 16, etc., and make a larger impact head 3 smaller Small or a single tooth seat 4 with the same impact cutting height is divided into multiple tooth seats 4, the single-layer impact head 3 with the same impact cutting height is changed to a combination of multi-layer impact heads 3, etc., each of the combined impact head 17 The small impact head 3 uses the same power source 18, etc., so that the impact area of each small impact head 3 is reduced, the impact force is large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com