A kind of lateral vibration test device and test method of threaded fastener

A threaded fastener and lateral vibration technology, which is applied in vibration testing, measuring devices, testing of machine/structural components, etc., can solve the problem that the testing system cannot detect the change, amplitude and vibration acceleration of the lateral shear force of the bolt specimen in real time Difficult to adjust, complex structure of the lateral vibration testing machine, etc., to achieve the effects of stepless amplitude modulation vibration acceleration, real-time monitoring, and large vibration acceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention is described in further detail below in conjunction with accompanying drawing:

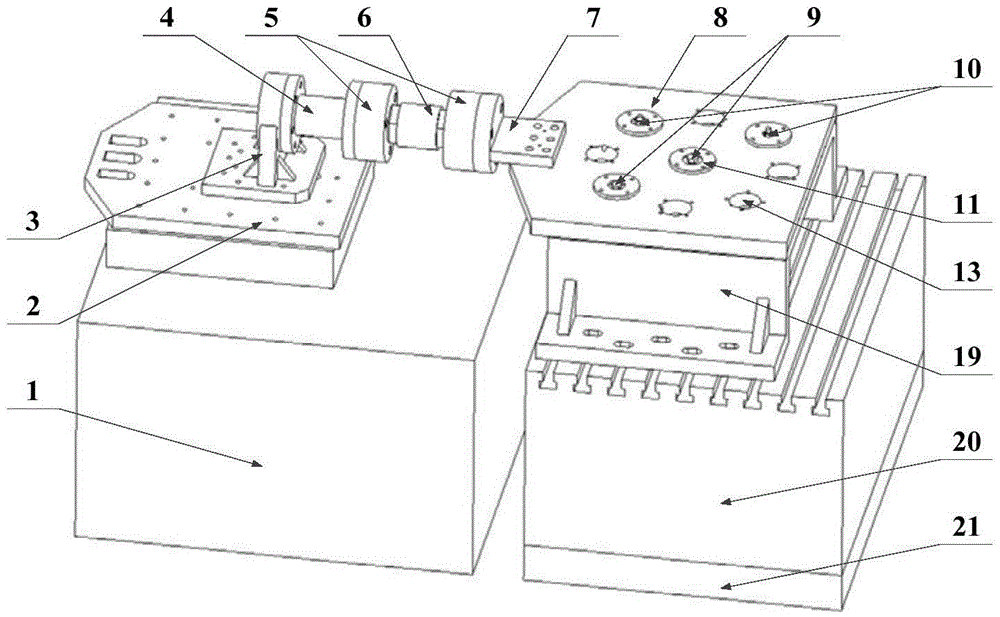

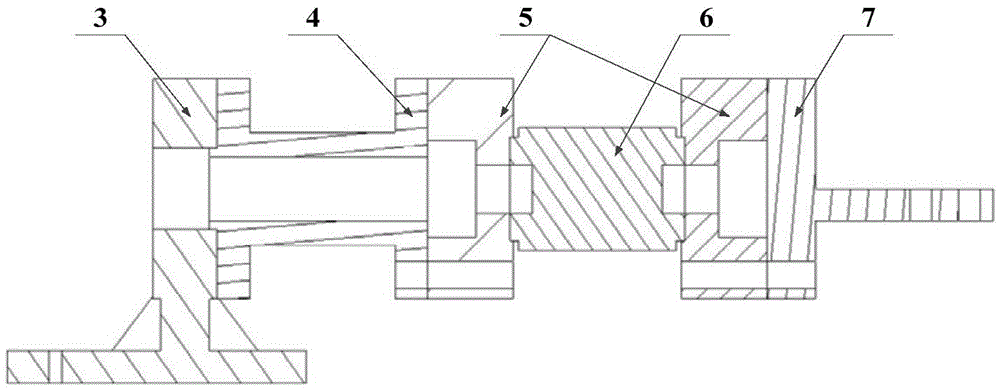

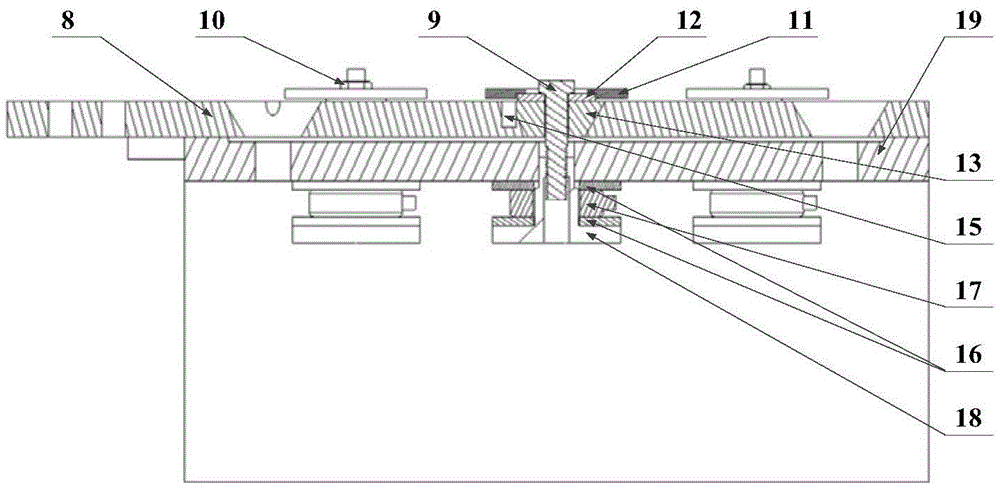

[0044] see Figure 1 to Figure 8 , the lateral vibration test device for threaded fasteners of the present invention includes a lateral vibration platform, a transmission system, a fixture system, a mounting base and a measuring device; the lateral vibration platform includes a vibration platform base 1, a horizontal vibration table 2 and a vibration source, and the vibration source The excitation coil is used, the output end of the vibration source is fastened with the horizontal vibrating table 2 by bolts, the horizontal vibrating table 2 is connected with the vibration platform base 1 through a ball chain, and multiple sets of threaded holes for connecting the transmission system are opened on the horizontal vibrating table; The system includes a transmission seat 3, a cylindrical transmission part 4, a sensor flange 5, a tension pressure sensor 6, and a T-shaped tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com