Soil-structure contact surface shear test device capable of realizing bidirectional high-frequency vibration

A technology of shear test and high-frequency vibration, applied in the direction of applying stable shear force to test the strength of materials, measuring devices, instruments, etc., can solve problems such as normal force fluctuations on the contact surface, and achieve constant vertical pressure output, Avoid the effect of normal pressure fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

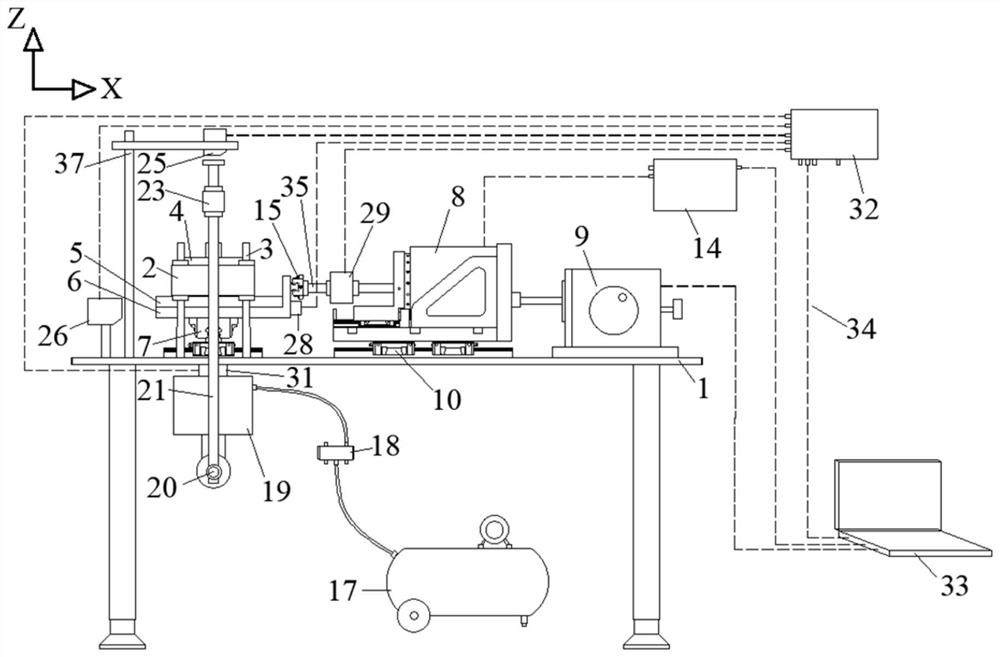

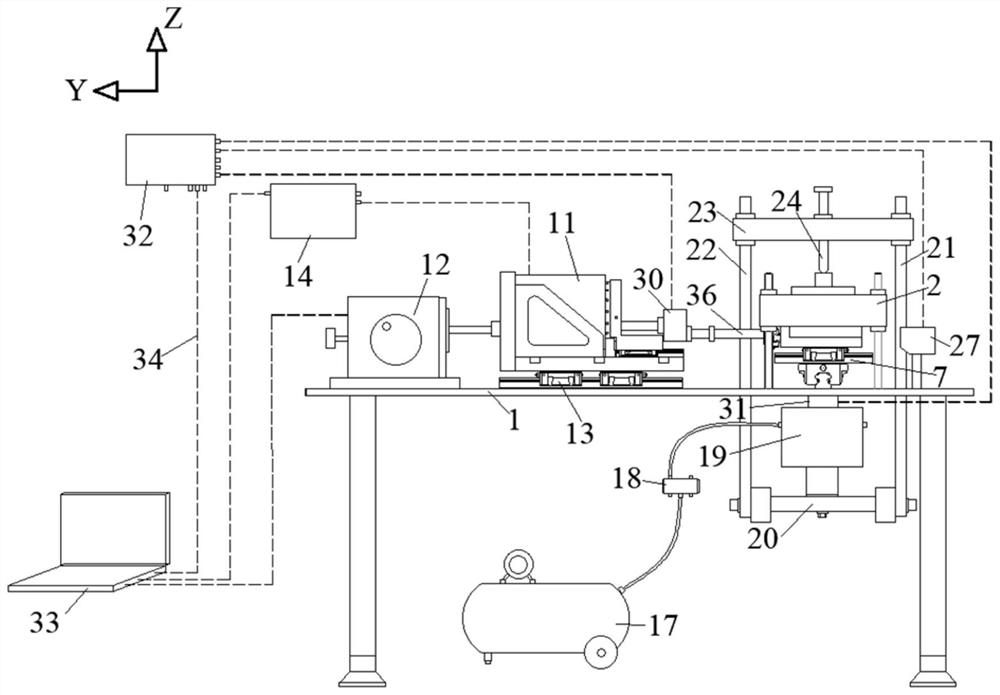

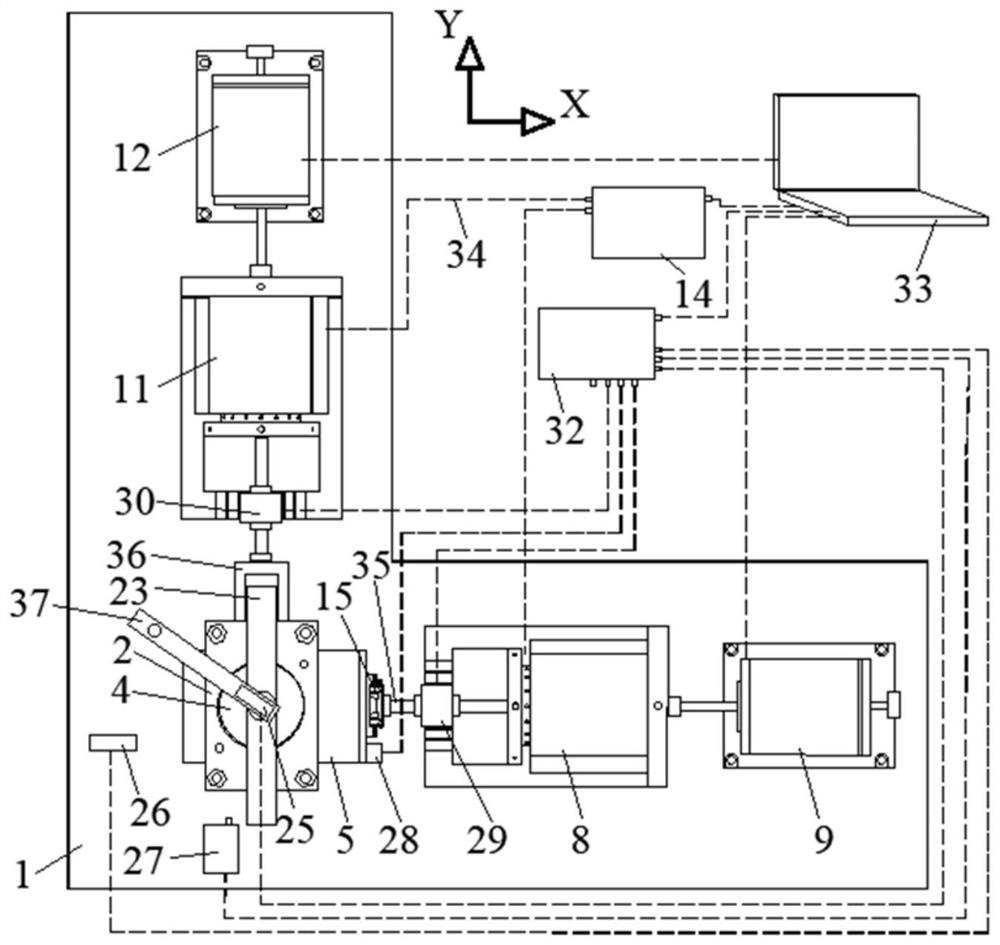

[0039] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a soil-structure interface shear test device that can realize bidirectional high-frequency vibration includes a test unit, a loading unit (for horizontal loading and Z-direction loading) and a measurement and control unit (for measurement acquisition and control) . Relevant components mainly include: test bench 1, upper shear box 2, upper shear box fixing mechanism 3, pressure transmission plate 4, structural panel 5, tray 6, double slide rail motion platform 7, first voice coil motor module 8, The first stepper motor 9, the first single-rail motion platform 10, the second voice coil motor module 11, the second stepper motor 12, the second single-rail motion platform 13, the servo driver 14, and the first linear slide 15. Second linear slide rail 16, air compressor 17, electro-hydraulic servo valve 18, cylinder 19, lower beam 20, first column 21, second column 22, upper beam 23, dowel bar 24,...

Embodiment 2

[0054] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a soil-structure interface shear test device that can realize two-way high-frequency vibration includes a test unit, a loading unit, and a measurement and control unit. The test unit includes a test bench 1 and an upper shear box set on the test bench 1. Fixing mechanism 3, the upper shearing box 2 that is arranged on the upper shearing box fixing mechanism 3, the double slide rail moving platform 7 that is arranged on the test bench 1, the pallet 6 that is arranged on the double sliding rail moving platform 7 and is arranged on The structural panel 5 on the tray 6 and located below the upper shear box 2, the loading unit includes an X-direction voice coil motor loading mechanism, a Y-direction voice coil motor loading mechanism and an upper shear box 2 corresponding to the tray 6 respectively. The adapted Z-direction loading mechanism and the measurement and control unit are respectively adap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com