Sandwich type frictional welding tool and method of metal welding part

A metal welding and sandwich technology, applied in the field of friction welding, can solve the problems of low strength and voids of metal composite surfaces, and achieve the effects of high reliability and quality, improved strength and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

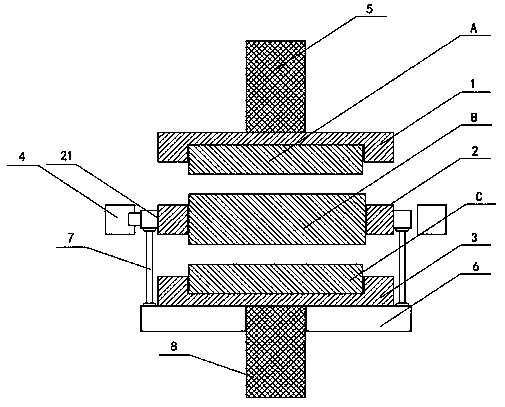

[0038] The following will be attached Figure 1~4 The present invention is further described with examples.

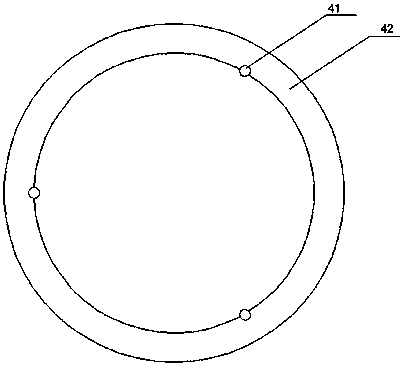

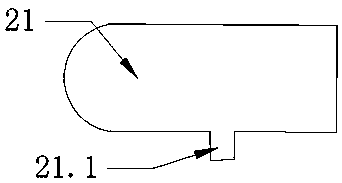

[0039] Sandwich-type friction welding tooling for metal welding parts, including an upper fixture 1 for clamping an upper metal piece, a middle fixture 2 for clamping a middle metal piece, and a lower fixture 3 for clamping a lower metal piece, and is characterized in that It includes a rotating impact assembly 4 connected to an external driving device and a pressure assembly 5 mounted on the upper clamp 1 for pressing the upper metal piece, the middle metal piece and the lower metal piece. The rotating impact assembly 4 is mounted on the middle layer On the outer periphery of the clamp 2, the rotating impact assembly 4 rotates at a high speed and impacts the middle clamp 2, pushing the middle clamp 2 to vibrate in the horizontal direction.

[0040] As shown in the figure, the metal parts to be welded are clamped by the upper, middle and lower three-layer clamps, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com