Electronic device, camera module and assembly method thereof

A lens module and lens technology, which is applied in installation, optics, instruments, etc., can solve the problems of incomplete appearance, long assembly time, lens impact, etc. of the lens module, so as to improve assembly yield, reduce impact, and reduce screws the effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

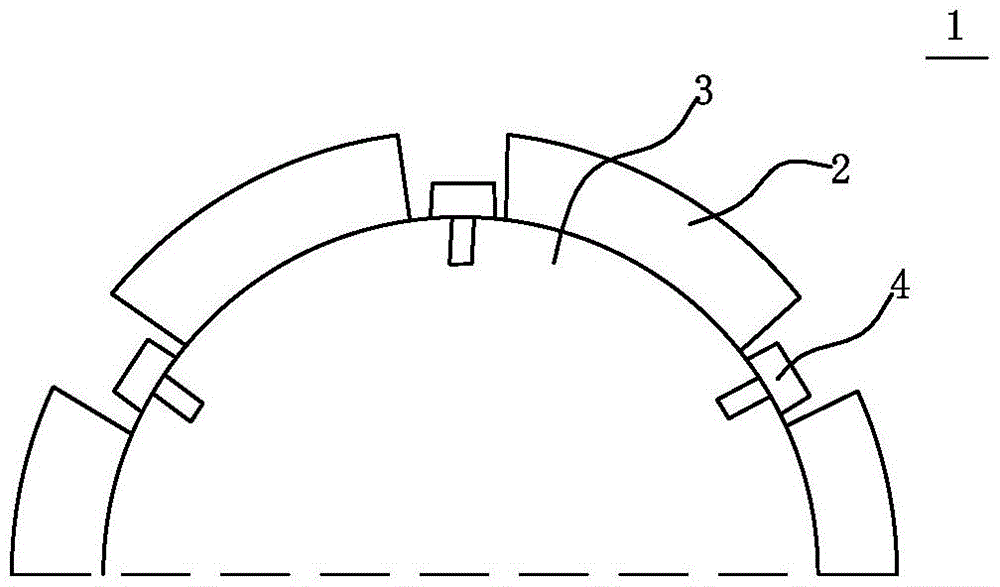

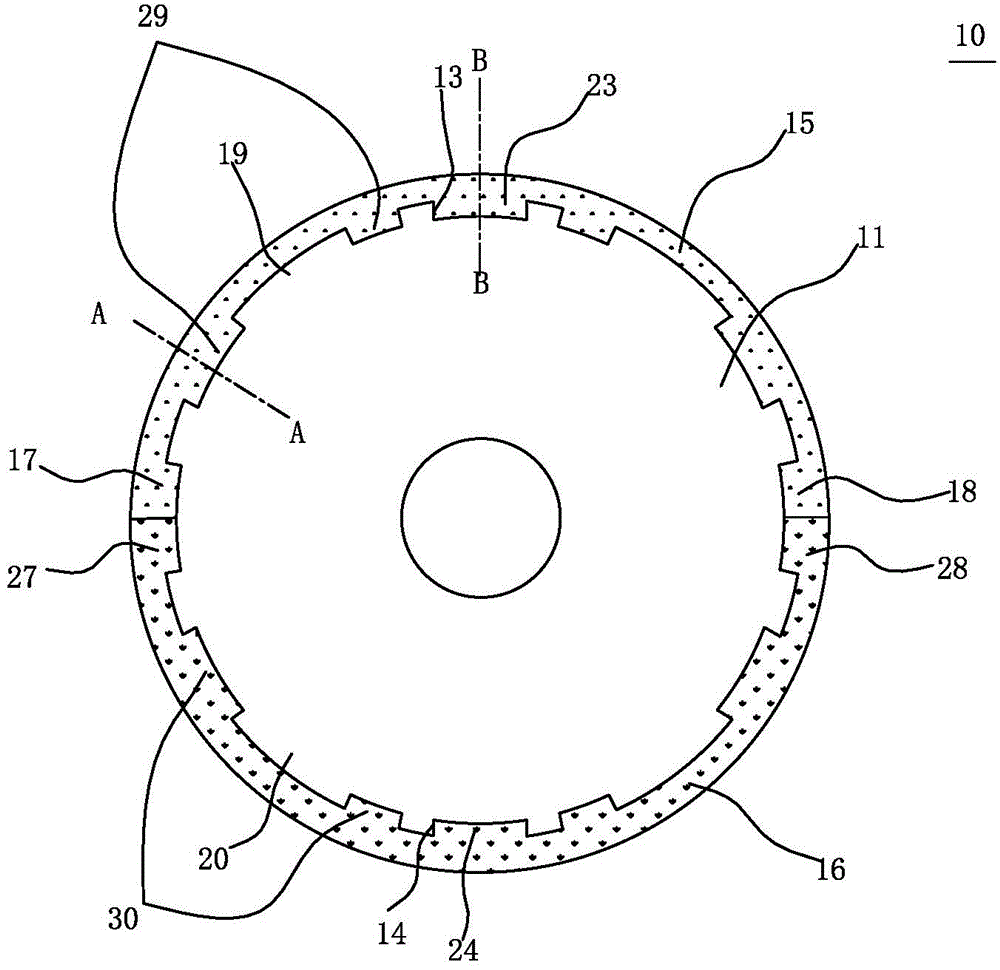

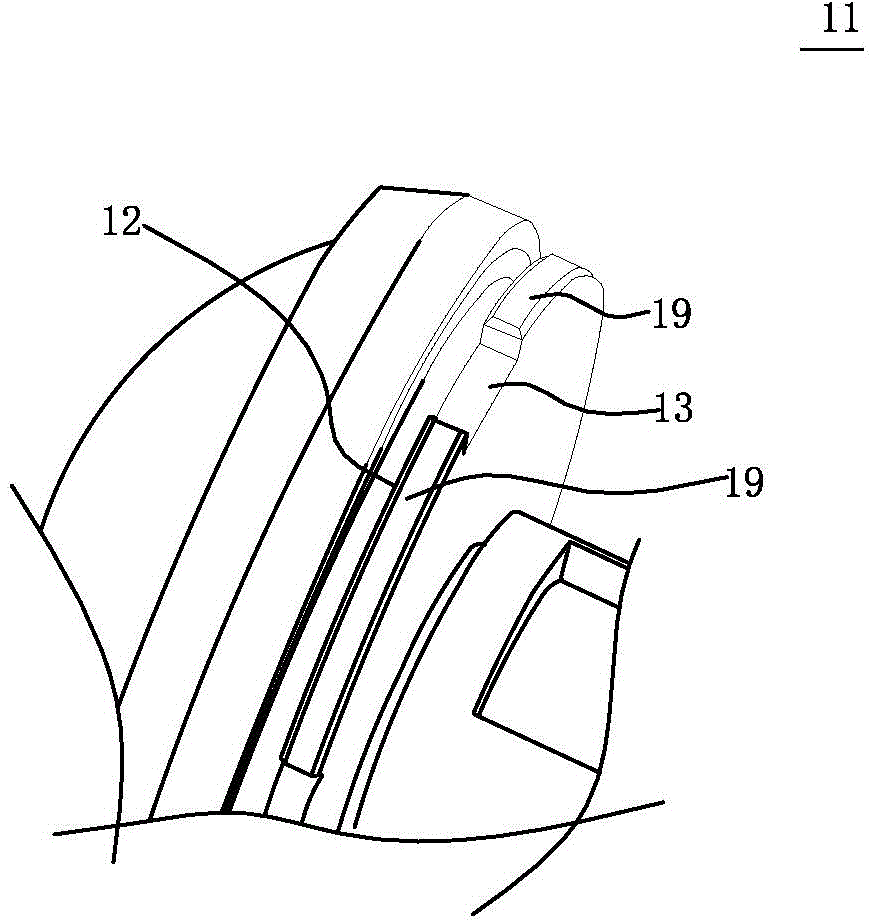

[0024] See Figure 2-Figure 6 , figure 2 Shown is a schematic diagram of the lens module according to the present invention, image 3 Shown is a schematic diagram of a lens according to the invention, Figure 4A Shown is a schematic diagram of a lens ring according to the present invention, Figure 4B Shown is a sectional view of a lens ring according to the present invention, Figure 5 Shown is a schematic cross-sectional view of the lens module according to the present invention along line AA, Image 6 Shown is a schematic cross-sectional view of the lens module according to the present invention along line BB. The present invention provides an electronic device having the following lens module 10 , wherein the electronic device is, for example, a projector, a camera, a computer or other palm-sized electronic devices. The lens module 10 includes a lens 11 and a lens ring 21 . The outer edge 12 of the lens 11 has a first positioning portion 13 and a second positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com