An anti-extrusion and tensile-resistant power cable

An anti-extrusion technology for power cables, applied in the field of anti-extrusion and stretch-resistant power cables, can solve problems such as failure to ensure smooth transmission of power and communication, easy deformation of wires in the cable core, economic losses, etc., to reduce the risk of damage , Improve the extrusion resistance, improve the effect of elastic deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

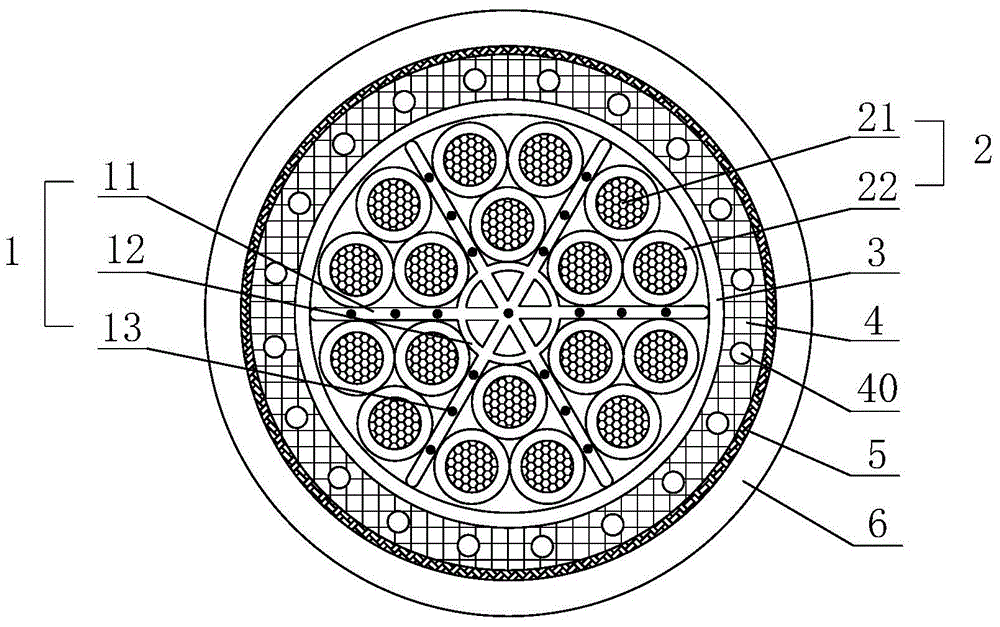

[0012] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of an extrusion-resistant and tensile-resistant power cable proposed by the present invention.

[0013] refer to figure 1 , an anti-extrusion and stretch-resistant power cable proposed by the present invention, comprising a cable core, a wrapping layer 3, an elastic anti-extrusion layer 4, a shielding layer 5, and a sheath layer 6;

[0014] The cable core is composed of an elastic support frame 1 and a plurality of conductors 2. The conductor 2 includes a conductor 21 located in the middle, and the conductor 21 is covered with an insulating layer 22. The support plates 12 are integrated, and the support plates 12 are arranged radially along the cylinder 11. One end of all the support plates 12 is located in the cylinder 11 and meets at the central axis of the cylinder 11, and the other end passes through the side wall of the cylinder 11. The outer side of the cylinder 11 leans against the wrappi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com