Lightning arrester and its manufacturing process

An air-termination device and air-termination rod technology, which is applied in hot-dip plating process, metal material coating process, over-voltage arrester using spark gap, etc. It can reduce the lightning current pulse intensity, improve the discharge effect, and increase the surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

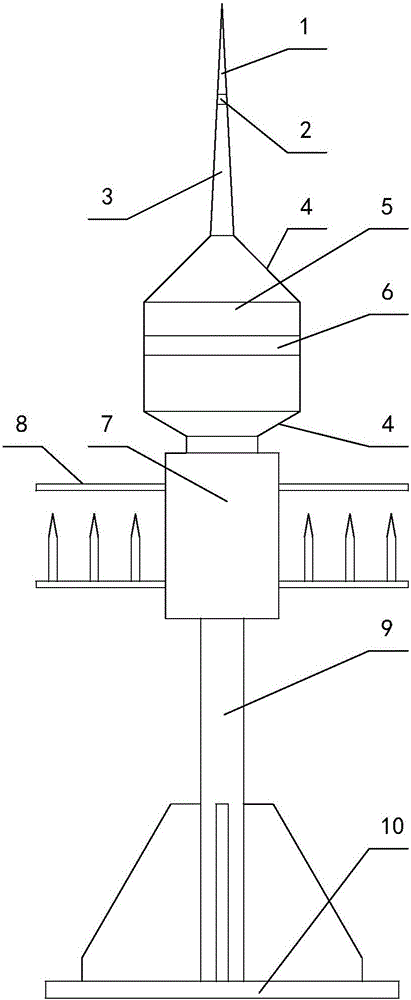

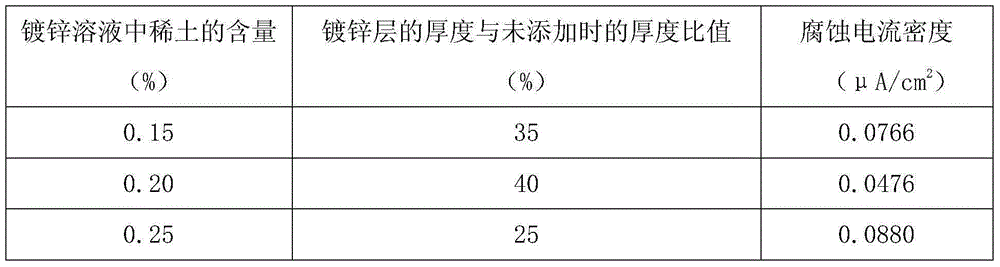

[0026] It can be seen from the schematic diagram of the structure of the lightning protection air-termination device of the present invention shown in the accompanying drawings that it includes an air-termination pole with a pointed tip 1 and a mounting base 10 for connecting with the roof of a building. The air-termination pole is vertically connected to Install on the base 10. It also includes a pre-discharge device and a lightning protection device. The pre-discharge device and the lightning protection device are both arranged in the middle of the lightning rod, and the lightning protection device is located below the pre-discharge device; the lightning rod The surface is coated with a galvanized layer through hot-dip galvanizing, and the galvanizing solution during galvanizing contains rare earths, and the content of the rare earths is 0.1% to 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com