Railway fine tool machining auxiliary clamp

An auxiliary fixture and precision tool technology, applied in metal processing equipment, metal processing mechanical parts, clamping and other directions, can solve the problems of difficult positioning, low production efficiency, displacement, etc., to achieve safe and effective fixation, cost reduction, use handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to further illustrate the present invention, introduce below in conjunction with accompanying drawing of description:

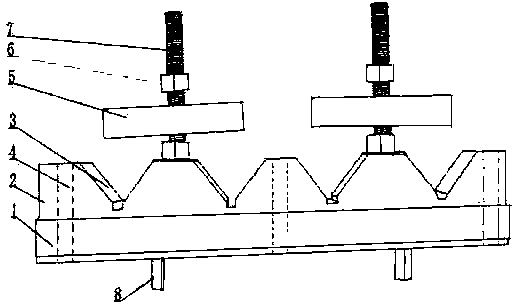

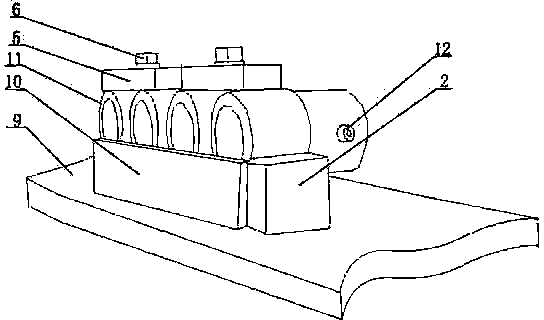

[0012] Refer to attached figure 1 , Auxiliary fixture for railway precision tool processing, which includes base 1, bar iron block 2, V-shaped groove 3, fixing hole 4, pressing block 5, nut 6, screw rod 7 and positioning pin 8, the lower end of base 1 is equipped with Two positioning pins 8, the upper end of the base 1 is connected to the bar-shaped iron block 2, and there are four V-shaped grooves 3 on the bar-shaped iron block 2, and the bar-shaped iron block 2 forms three isosceles trapezoidal blocks in the middle and two isosceles trapezoidal blocks at both ends. The upper ends of the two right-angled trapezoids and the middlemost isosceles trapezoid are respectively provided with fixing holes 4, and the upper ends of the other two isosceles trapezoids are designed with screw rods 7, and the screw rods 7 are covered with pressing blocks. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com