Automatic screw filling machine

A filling machine and fully automatic technology, which is applied to screwdrivers, wrenches, manufacturing tools, etc., can solve the problems of low reliability of mechanized operation, troublesome adjustment of screw size, and low efficiency during use, and achieve simple structure, high automation efficiency, and easy processing convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

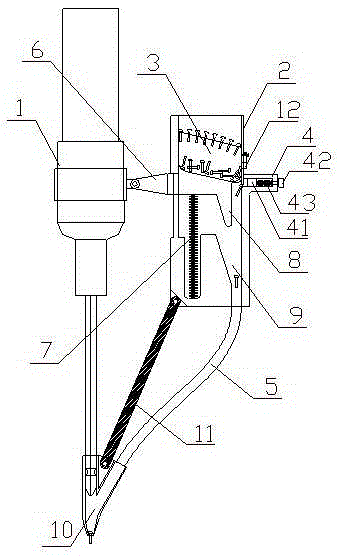

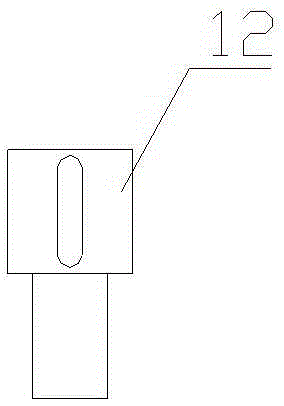

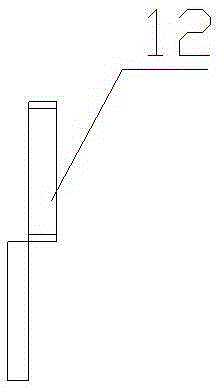

[0024] Example: see figure 1 , figure 2 as well as image 3 , a fully automatic screw filling machine, comprising an electric batch 1 and a screw filling device, the screw filling device comprising a screw storage box 2, a screw arrangement clamp 3, a material distribution clamp 4 and a screw conveying pipeline 5; the specific implementation is, in the screw The storage box 2 is provided with a box cover, which can close the screw storage box 2 .

[0025] The upper part of the screw storage box 2 has a storage cavity, and the side of the storage cavity close to the electric batch 1 is provided with a chute in the vertical direction. The upper edge of the screw arrangement clamp 3 is arc-shaped, and one end close to the chute is higher than the other end, and a screw arrangement groove is provided on the upper edge of the screw arrangement clamp 3 (along its length direction), so that the screws Under the action of gravity, it can slide freely along the chute. The screw ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com