Special powder automatic filling device

An automatic filling and powder technology, applied to explosives processing equipment, offensive equipment, explosives, etc., can solve problems such as bulky, expensive, difficult installation and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

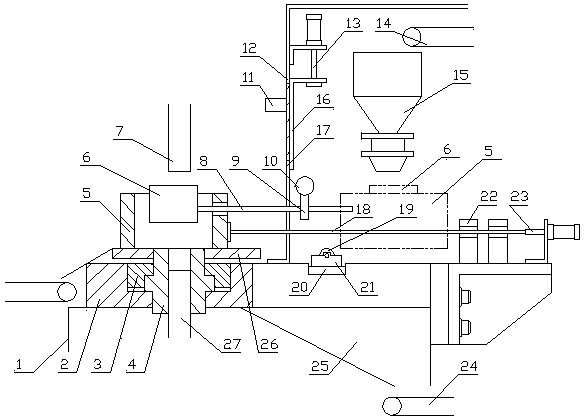

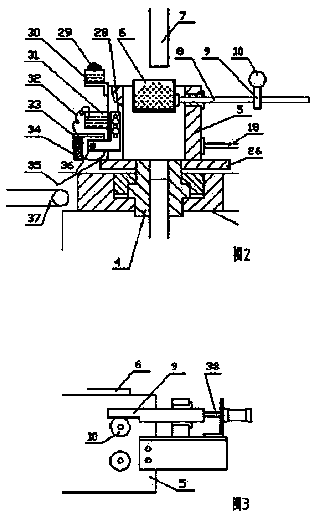

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0015] see figure 1 , figure 2 , image 3 , when charging the material box 6, the square frame 5 is located under the powdery material hopper 15 and above the funnel 25, and is in a suspended state under the support of the driving round rod 18. After the material box 6 in the square frame is fed , the lifting door 16 on the dividing plate 12 is opened, and the square frame and the material box on it are pushed toward the die 4 under the promotion of the driving round rod 18. When approaching the center of the die, the bottom surface of the square frame contacts the top surface of the slide plate 26, Thereby closing the bottom surface of the square frame, then the third piston rod 38, the columnar rack 10, the gear 9, and the rotating rod 8 act to make the material box 6 rotate, and the powder is dumped in the square frame, and the square fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com