A sun room short column structure and its cutting method

A sun room and short column technology, which is applied in the direction of building structure, construction, and building material processing, can solve structural problems, problems that affect the smooth progress of the lifting and installation process, and achieve failure prevention, force balance, and structural safety protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following is an example of a high-rise sun room 9 with a weight of 162T, and describes preferred embodiments of the present invention in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit invention.

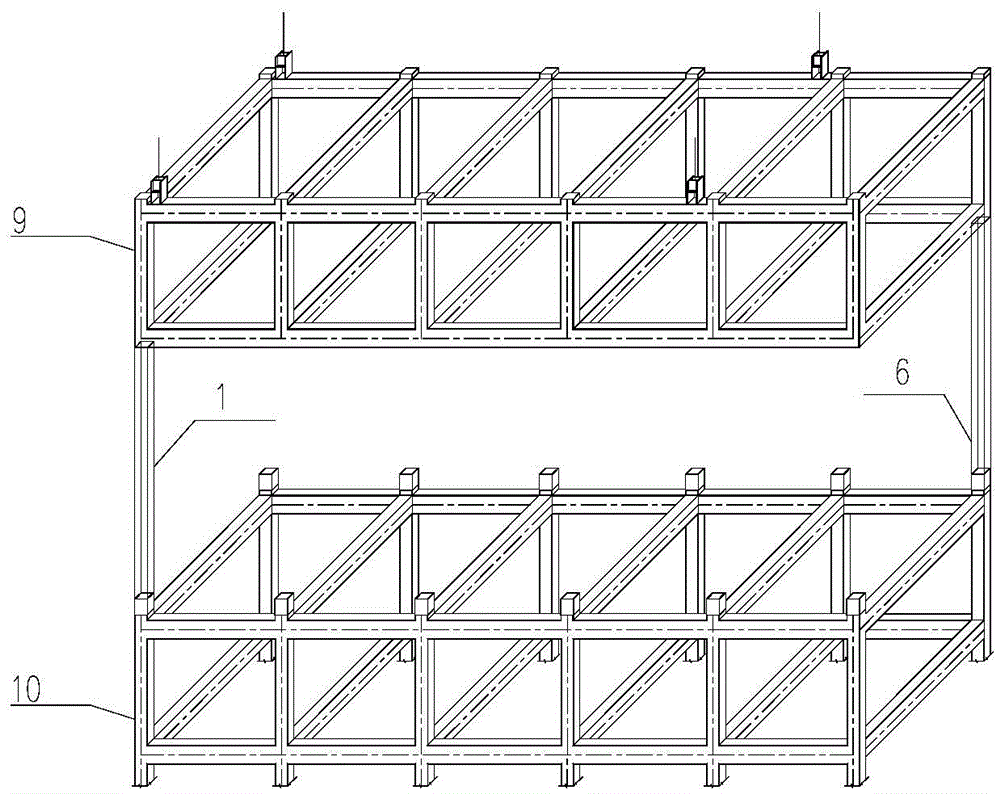

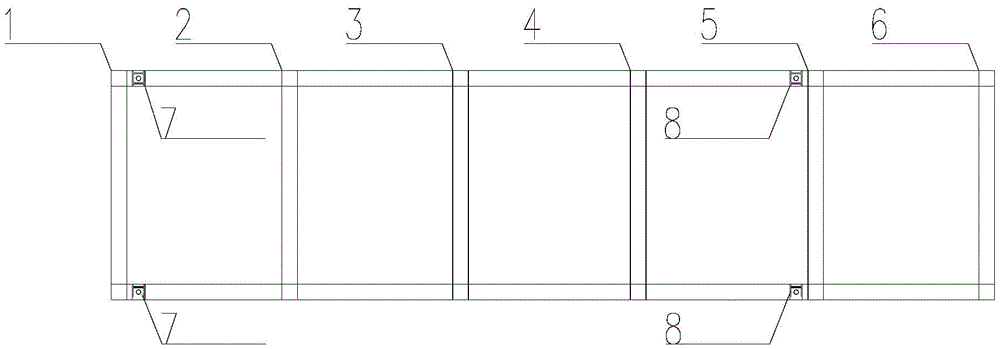

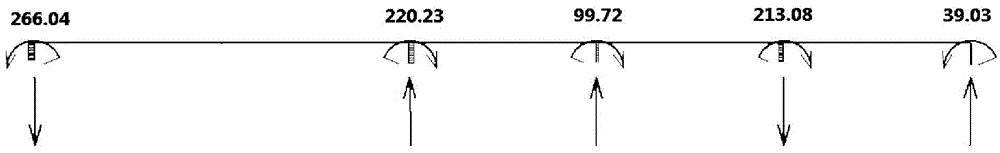

[0027] Such as figure 1 and figure 2 As shown, the high-rise sun room 9 and the low-rise sun room 10 are connected with the sun room short column structure to form the whole sun room. The sun room short column structure includes a first temporary column 1, a second temporary column 2, a third temporary column 3, The fourth temporary column 4, the fifth temporary column 5 and the sixth temporary column 6, the first temporary column 1, the second temporary column 2, the third temporary column 3, the fourth temporary column 4, the fifth temporary column 5 and the sixth Temporary columns 6 are arranged at equal inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com