Multistage-control-based batching weighing control method

A control method and multi-stage technology, applied in the field of weighing, can solve the problems of difficult control of precision, difficulty in improving the speed and accuracy of raw material weighing at the same time, and the influence of the amount of material falling in the air, so as to achieve fast weighing of material batching and solve the problem of material batching Weighing speed and accuracy contradict each other, and the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

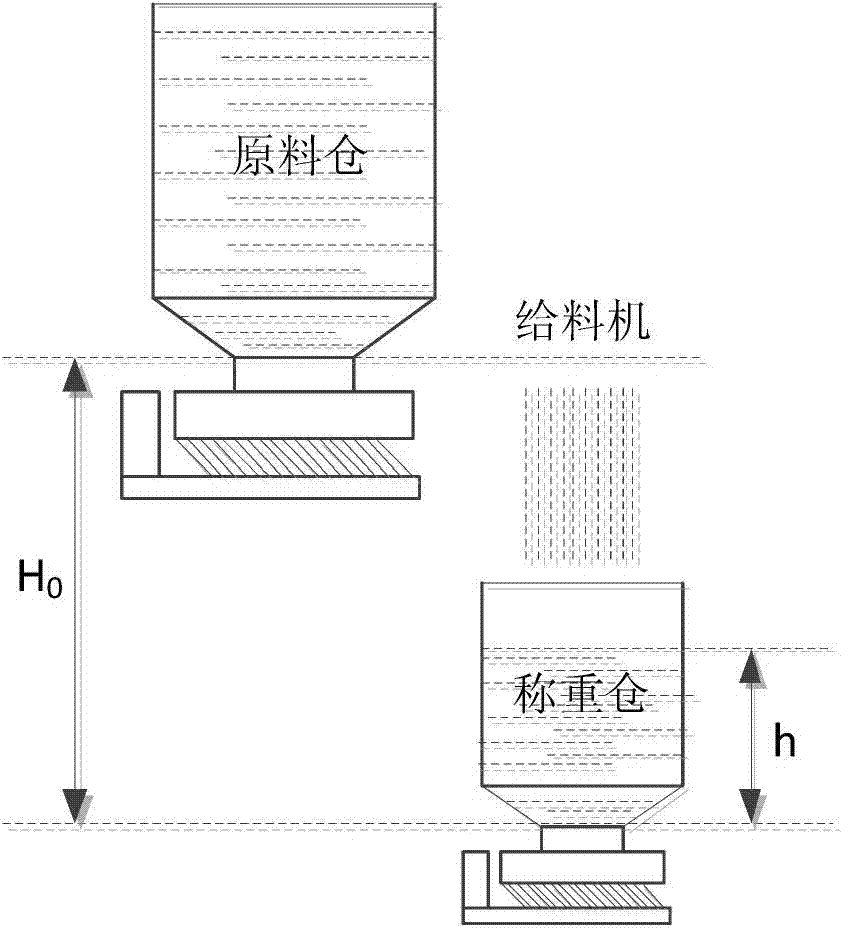

[0035] figure 2 It is a schematic diagram of the material batching and weighing structure of the present invention. As shown in the figure, there is a gap distance between the feeder and the weighing bin, which will affect the accuracy of weighing.

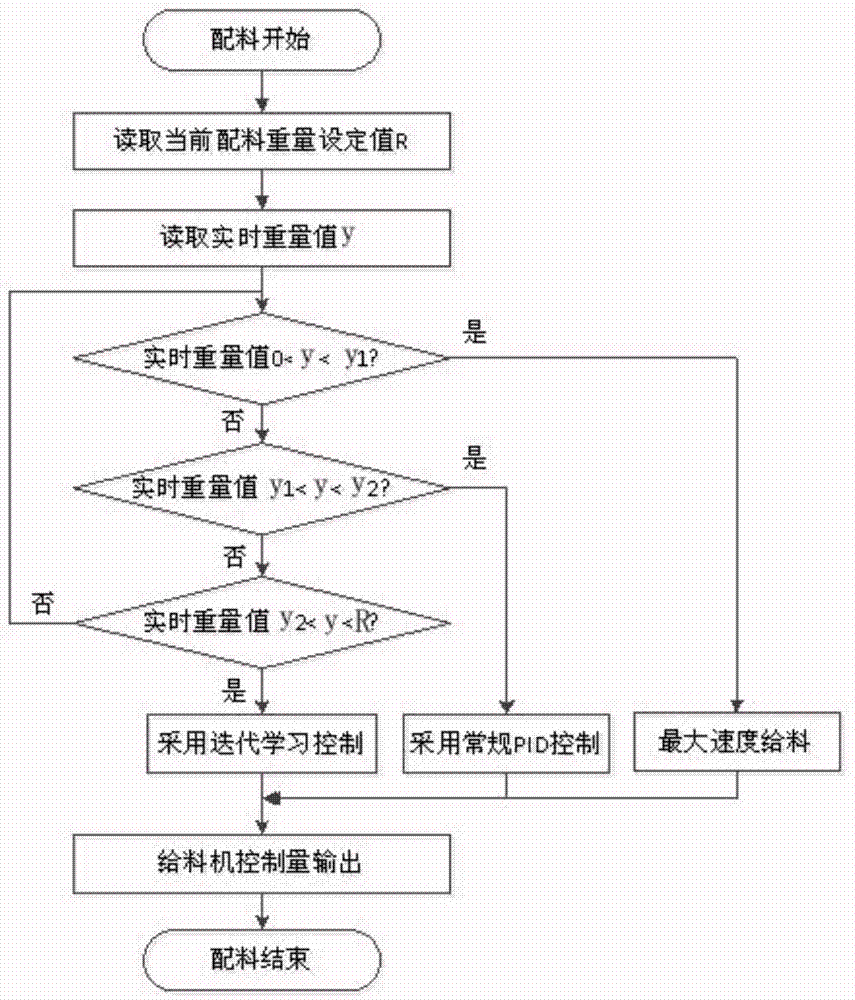

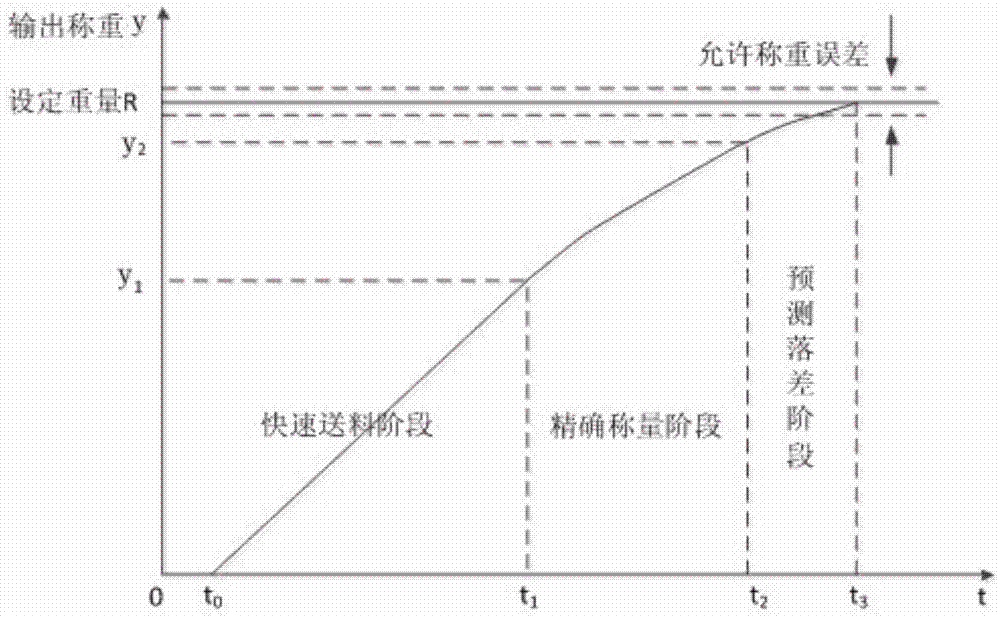

[0036] A batching weighing control method based on multi-stage control in the present invention divides the batching weighing process into three stages, and uses different control methods for control. The specific process is as follows:

[0037] The first stage: fast feeding stage, that is, to set the total weight value of weighing and the weight threshold of the first stage. When the actual feeding amount is less than or equal to the weight value of the first stage, any material will be fed at the same constant maximum speed. quick batching;

[0038...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com