Weighing device applied to high-temperature working environment

A working environment and weighing device technology, applied in the field of weight detection, can solve problems such as short service life, low weighing accuracy, and low stability of sensor weighing, and achieve the effect of improving service life and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

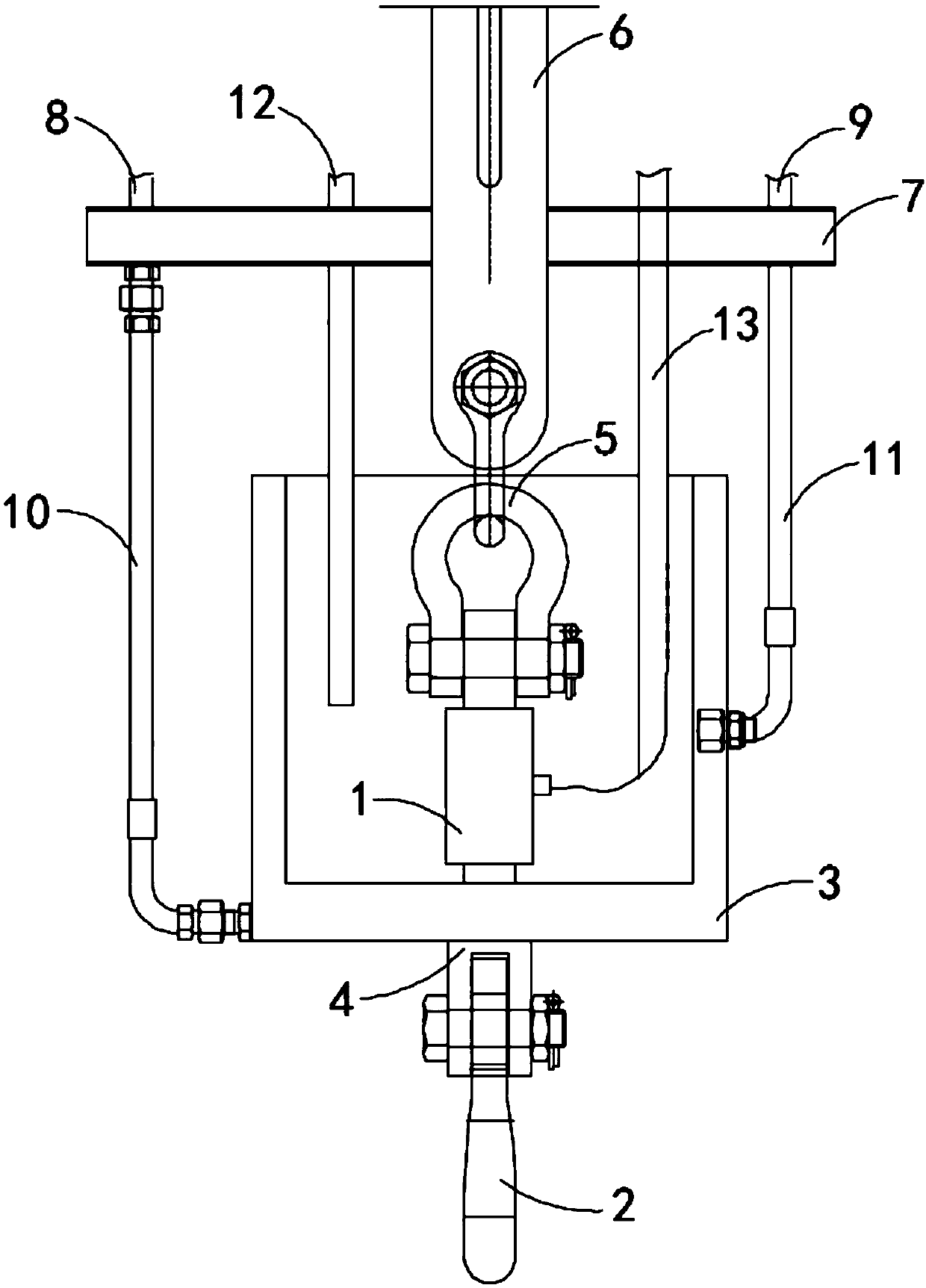

[0013] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0014] refer to figure 1 , a weighing device adapted to high-temperature working environment conditions, including a load cell 1 and a hook 2, the load cell 1 is provided with a water-cooled heat shield 3 with an open upper end, and the water-cooled heat shield 3 is water-cooled The box body, the lower end of the load cell 1 is fixedly connected with the inner bottom surface of the water-cooled heat shield 3, the lower end of the water-cooled heat shield 3 is fixedly connected with the upper end of the hook 2 through the water-cooled lower link 4, and the water-cooled lower link 4 is connected with the hanger. The hooks 2 are fixedly connected by bolts, the upper end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com