Mounting member, and seat equipped with airbag module

A technology for installing parts and airbags, applied to seat frames, vehicle parts, vehicle seats, etc., can solve the problems of time-consuming and other problems, and achieve the effect of simple structure, high deployment performance, and simple assembly operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

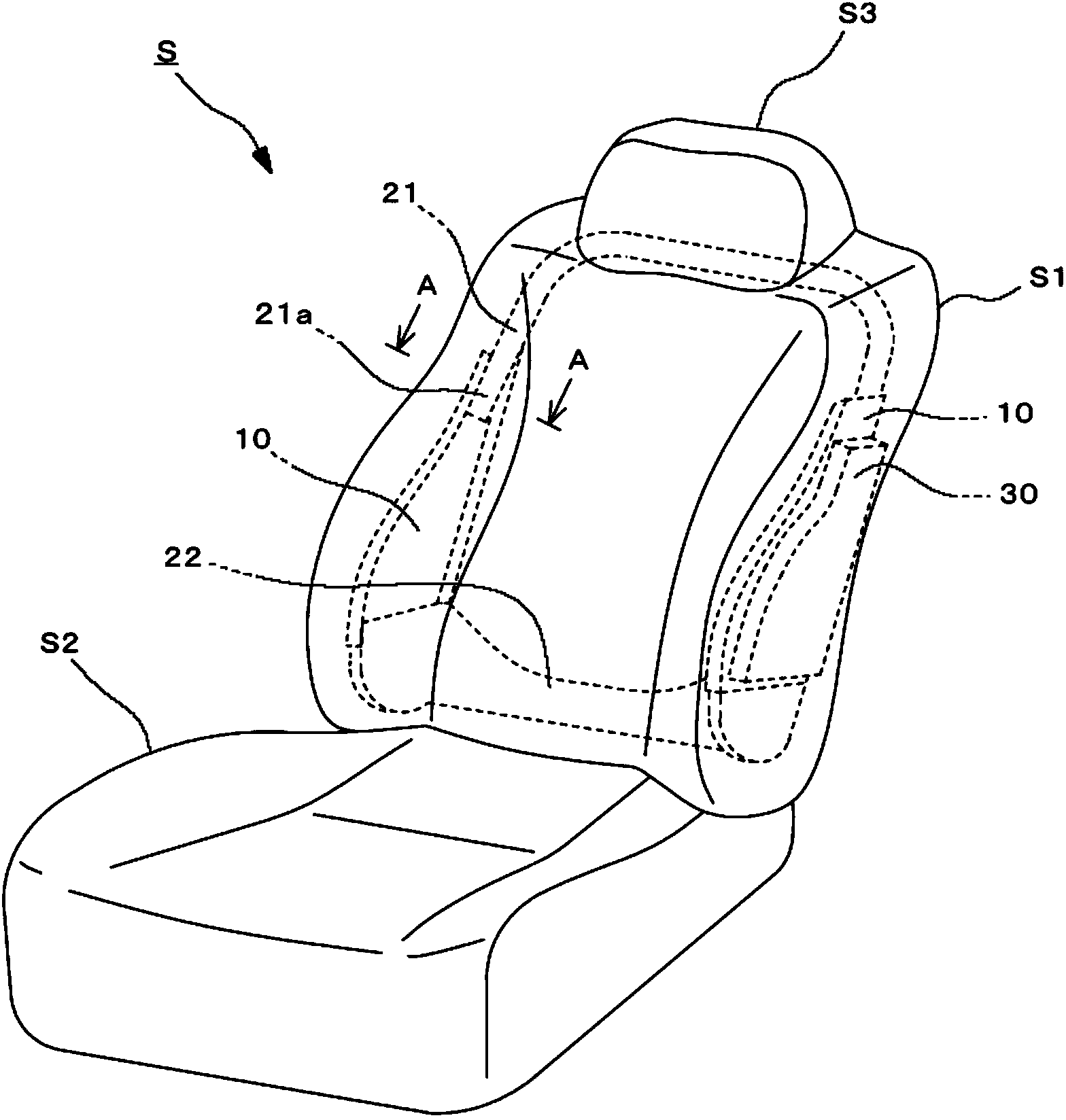

[0113] Such as figure 1 As shown, the vehicle seat S according to this embodiment is composed of a seat back S1 , a seat portion S2 , and a headrest S3 .

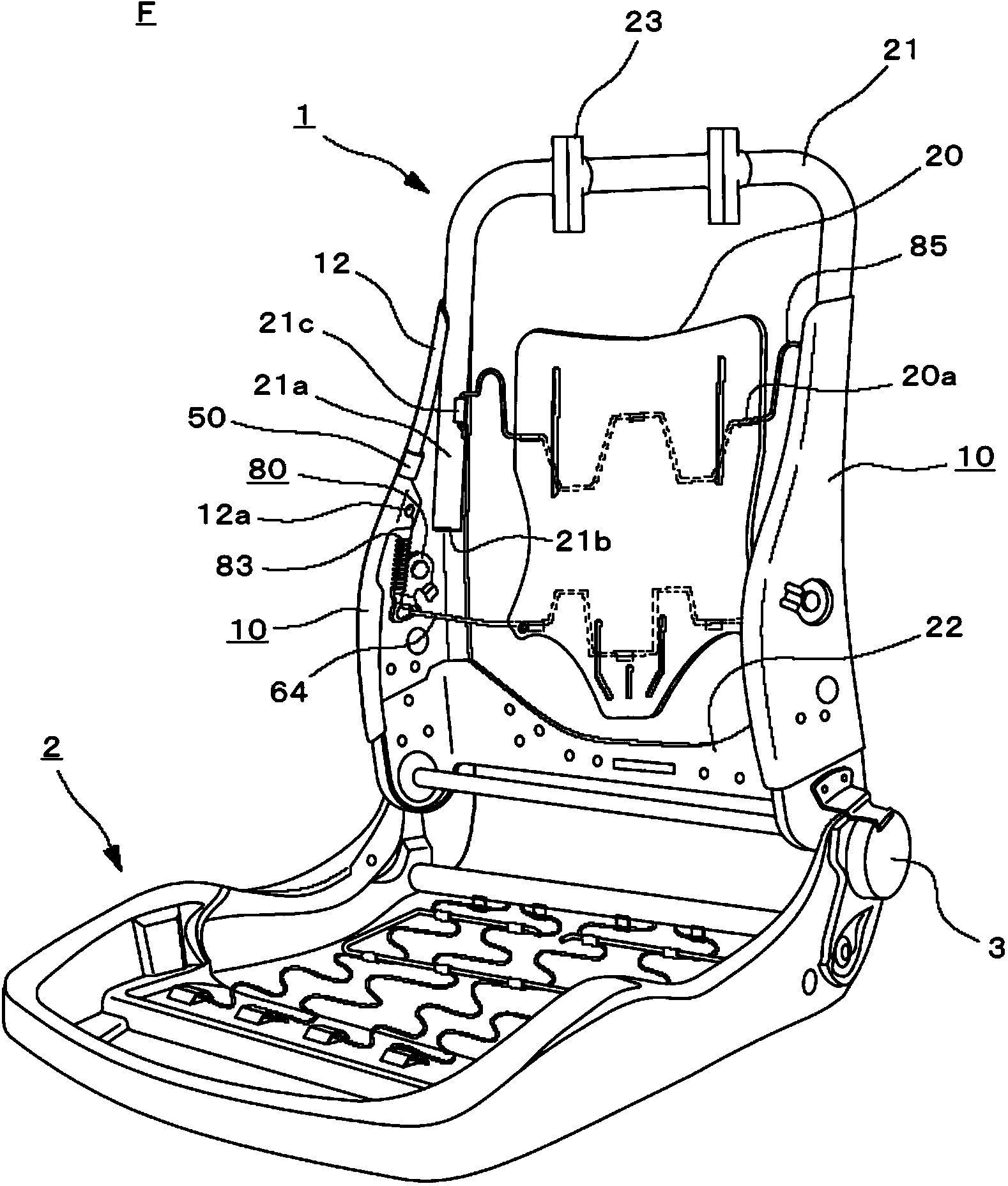

[0114] figure 2 The seat frame F shown is provided in a vehicle seat S. As shown in FIG. The seat frame F is composed of a seat back frame 1 as a frame of the seat back S1 and a seat frame 2 as a frame of the seat portion S2. The seat frame 2 and the seat back frame 1 are connected by a reclining mechanism 3 . The seat back S1 and the seat portion S2 are constituted by a cushion and a decorative cover provided on the outer sides of the seat back frame 1 and the seat frame 2 .

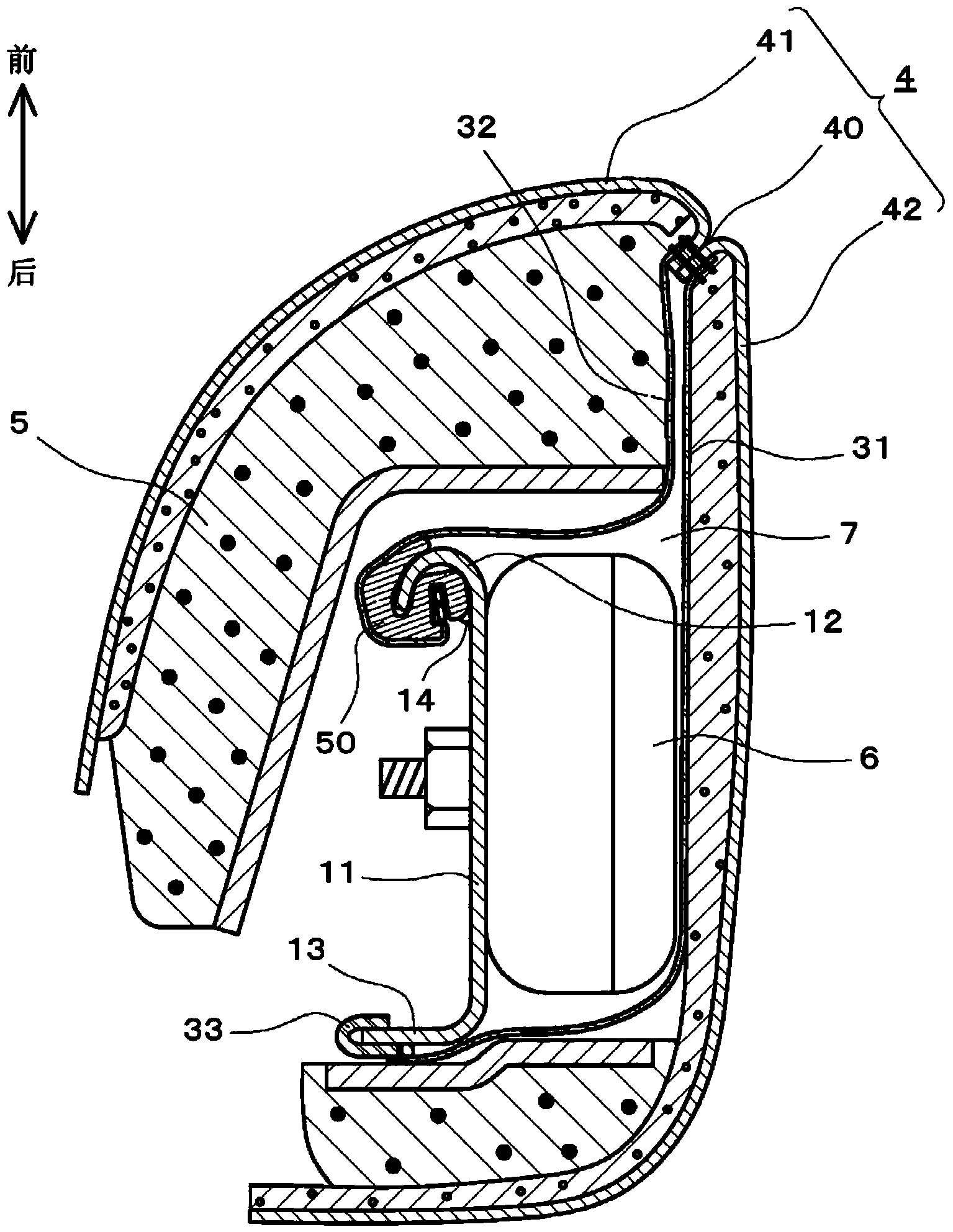

[0115] Such as figure 1 , figure 2 As shown, the seat frame S1 consists of the seat back frame 1, the cushion pad 5 placed on the seat back frame 1, the decorative cover 4 covering the seat back frame 1 and the cushion pad 5, and the broken part of the decorative cover 4 sewn on one end. The pair of fabrics 31 and 32 of the part 40 are main c...

Embodiment 2

[0179] according to Figure 17 ~ Figure 19 A second embodiment of the present invention will be described. In addition, description of the same configuration as that of the first embodiment is omitted.

[0180] Instead of the mounting part 50 of Embodiment 1, it is also possible to use Figure 17 ~ Figure 19 Mounting part 50 is shown.

[0181] In the attachment member 50 of this embodiment, the opening connected to the slit 69 is formed between the inner wall surface 59i and the curved surface 55b.

[0182] The slit 69 is provided at a position opposite to the groove 53 on the side wall of the locking portion 55 , and is an opening extending to the outer surface of the mounting member 50 . The gap surrounded by the first wall portion 59 and the second wall portion 60 constitute.

[0183] The first wall portion 59 extends from the curved surface 55a, and the second wall portion 60 extends from the curved surface 55b. The second wall portion 60 is opposed to the end portion...

Embodiment 3

[0219] refer to Figure 20 ~ Figure 24 A third embodiment of the present invention will be described. In addition, description of the same configuration as that of the first embodiment is omitted.

[0220] In the side frame 10 of the present embodiment, as Figure 20 As shown, the front edge portion 12 includes an upper portion 12a, a large curvature portion 12b, and a lower portion 12c. The upper part 12a is a part sandwiched between the upper end of the front edge part 12 and the large curvature part 12b, and the distance from the rear edge part 13 is substantially constant, or the lower part is located slightly away from the rear edge part 13 than the upper part.

[0221] The large curvature part 12b is a part sandwiched between the upper part 12a and the lower part 12c, and is a part where the distance from the rear edge part 13 increases rapidly. The large curvature portion 12b is drawn as a concave curve toward the rear of the seat S when viewed from the side. Over t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com