Foam dyeing method and device for towel fabric

A dyeing method and a technology of a dyeing device, which are applied in the field of dyeing technology, can solve problems such as large liquor ratio, production water, energy consumption for drying, and difficulty in cleaning, so as to reduce energy consumption, reduce residual dye overflow, and improve washing color. The effect of fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

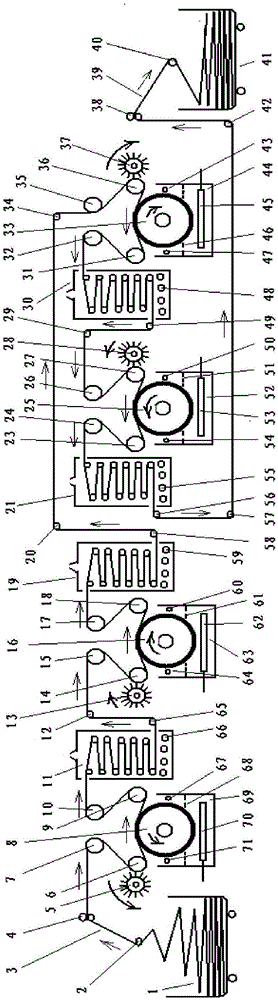

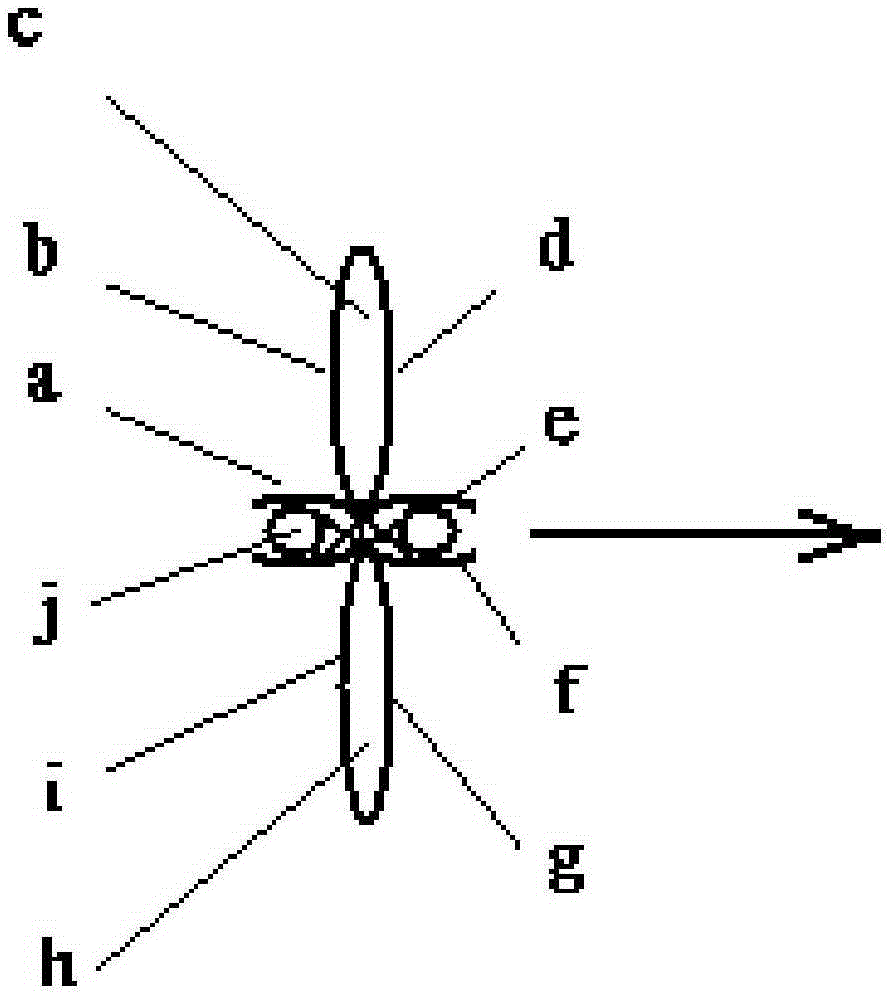

[0020] figure 1 Shown is a schematic diagram of a foam dyeing device for towel fabric provided according to a preferred embodiment of the present invention. figure 2 Shown is a cross-sectional view of a terry towel to be dyed according to a preferred embodiment of the present invention. Please also refer to figure 1 and figure 2 , the foam dyeing method of the towel fabric provided by the preferred embodiment of the present invention will be described in detail below.

[0021] In this embodiment, the towel fabric 3 to be dyed is composed of front pile c, reverse pile h, ground warp a, ground warp f, ground weft e, ground weft j, etc., which are used in the method of the preferred embodiment of the present invention During processing, the white fabric is refined and bleached so as to be easy to dye, and before entering the first dyeing solution tank 69, it is pre-wetted through immersion. First, the terry towel fabric 3 to be dyed exits from the cloth supply frame 1 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com