Dyeing agitating machine for sweet potato starch

A technology of sweet potato starch and mixer, which is applied in the direction of mixer with rotating stirring device, mixer, dissolving, etc., which can solve the problems of accelerating the oxidation, browning and coloring of sweet potato glue, and not having to add air.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

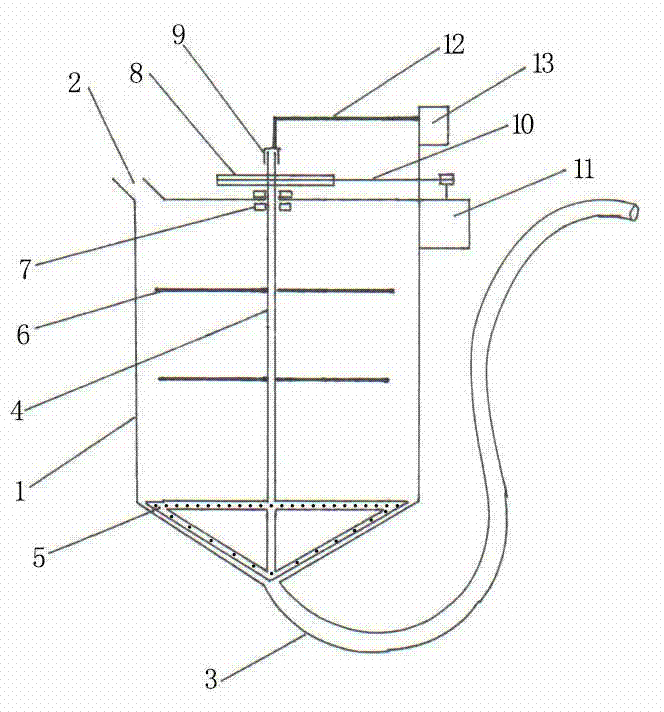

[0010] The sweet potato starch dyeing mixer has a feed inlet (2) on the upper side of the cylindrical conical bottom container (1), and a discharge steel wire rubber hose (3) is connected to the bottom of the cone. There is a hollow stirring shaft (4) in the center of the container. The stirring shaft (4) consists of a triangular hollow tube stirring fin (5), a horizontal stirring rod (6), a bearing (7), a pulley (8), and a sealing sleeve (9) drilled with many small holes from bottom to top. The belt pulley (8) is connected with the motor (11) to the sealing sleeve (9) through the belt (10), and connected with the air compressor (13) through the air pipe (12).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com