Polyester fabric printing method

A technology of polyester fabric and printing method, applied in the field of polyester fabric printing, can solve the problems of polluting the environment, long printing process, large water consumption, etc., and achieve the effects of good film-forming performance, shortened baking time, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A polyester fabric printing method, the specific implementation is as follows:

[0028] Step 1, preparing the color paste for the printing process;

[0029] In step 1, the specific method for preparing the color paste for the printing process is: uniformly mix the disperse dye, the thickener for printing, the oxidizing agent and water; wherein, the ratio of the raw materials for preparing the color paste is as follows in terms of mass percentage: disperse Red 3B 3%, interpenetrating network type polybutylacrylate modified amino silicon oxide compound 1%, high degree of substitution modified starch 2%, potassium permanganate 1%, the balance is water, the sum of the mass percentages of the above components is 100%.

[0030] Step 2, printing the polyester fabric with the color paste prepared in step 1, pre-baking, baking, and completing the printing of the polyester fabric;

[0031] In step 2, the pre-baking temperature is 80° C., and the pre-baking time is 3 minutes; th...

Embodiment 2

[0033] A polyester fabric printing method, the specific implementation is as follows:

[0034] Step 1, preparing the color paste for the printing process;

[0035] In step 1, the specific method for preparing the color paste for the printing process is: uniformly mix the disperse dye, the thickener for printing, the oxidizing agent and water; wherein, the ratio of the raw materials for preparing the color paste is as follows in terms of mass percentage: disperse Red 3B 3%, high degree of substitution modified starch 3%, dimethyl carbonate 1%, the balance is water, the sum of the mass percentages of the above components is 100%.

[0036] Step 2, printing the polyester fabric with the color paste prepared in step 1, pre-baking, baking, and completing the printing of the polyester fabric;

[0037] In step 2, the pre-baking temperature is 80° C., and the pre-baking time is 3 minutes; the baking temperature is 190° C., and the baking time is 90 s.

Embodiment 3

[0039] A polyester fabric printing method, the specific implementation is as follows:

[0040] Step 1, preparing the color paste for the printing process;

[0041] In step 1, the specific method for preparing the color paste for the printing process is: uniformly mix the disperse dye, the thickener for printing, the oxidizing agent and water; wherein, the ratio of the raw materials for preparing the color paste is as follows in terms of mass percentage: disperse Red 3B 3%, carboxymethyl cellulose ether 1%, hydrogen peroxide 1%, the balance is water, and the sum of the mass percentages of the above components is 100%.

[0042] Step 2, printing the polyester fabric with the color paste prepared in step 1, pre-baking, baking, and completing the printing of the polyester fabric;

[0043] In step 2, the pre-baking temperature is 80° C., and the pre-baking time is 3 minutes; the baking temperature is 190° C., and the baking time is 90 s.

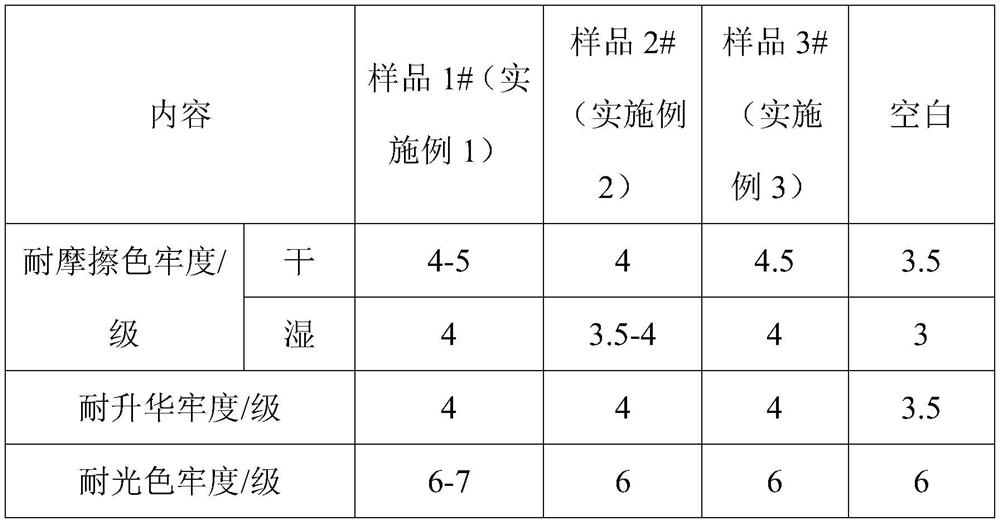

[0044] After adopting the method of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com